Electrode material, and preparation method and application thereof

A technology of electrode materials and positive electrode materials, applied in the field of electrode materials and their preparation, can solve the problem of high surface alkalinity and achieve the effect of stabilizing the evolution of lattice oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention aims to provide an electrode material, which has a micron-scale core-shell spherical structure, wherein the inner core is composed of positive electrode material, and the cladding layer is composed of amorphous Ni a mn b co c Composition B, where 0<a+b+c≤3, 0≤a≤3, 0≤b≤3, 0≤c≤3. The preparation method of the electrode material comprises the following steps:

[0046] S1. Dissolving the transition metal salt in absolute ethanol, stirring until the transition metal is completely dissolved, to obtain a solution;

[0047] S2, dissolving sodium borohydride in absolute ethanol, stirring until sodium borohydride is completely dissolved to obtain solution B;

[0048] S3. Dispersing the positive electrode material in the A solution prepared in step S1 to obtain a C solution;

[0049] S4. Under a protective atmosphere, slowly add the B solution prepared in step S2 to the C solution prepared in step S3; after the addition, stir to react;

[0050] S5, filte...

Embodiment 1

[0059] A preparation method of an electrode material, comprising the steps of:

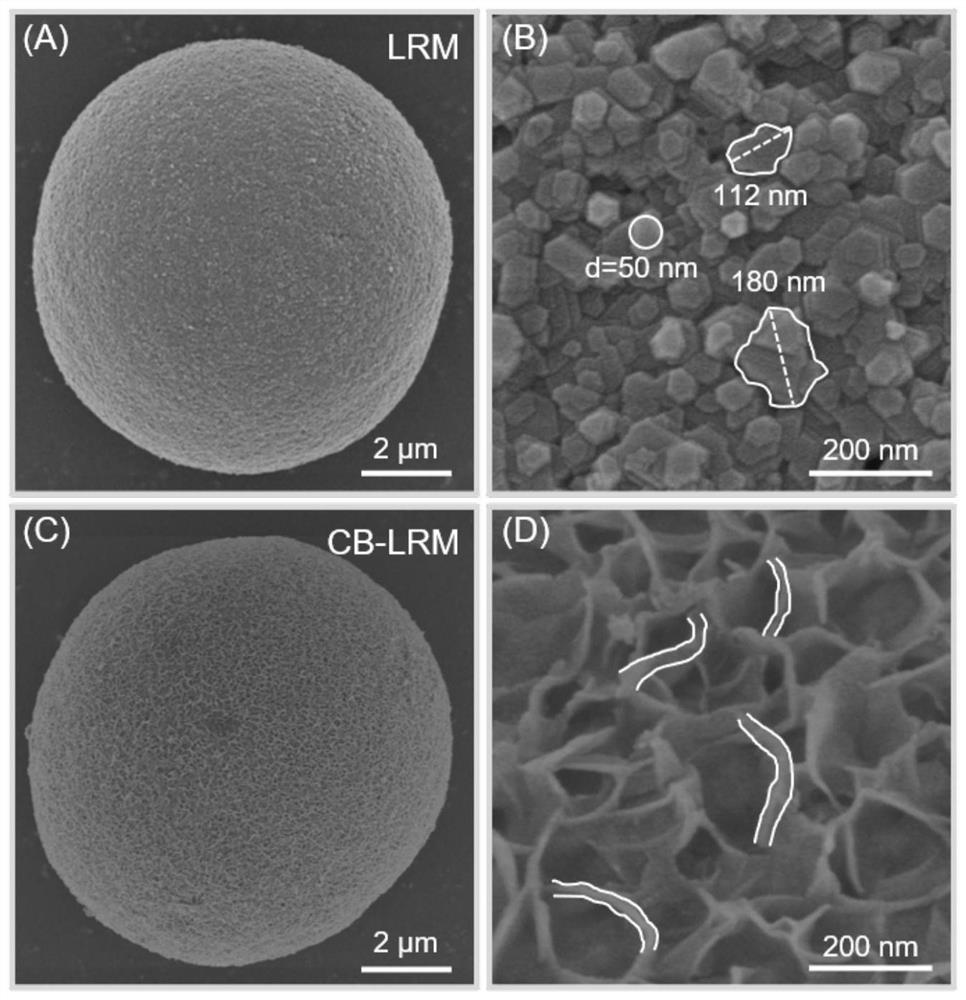

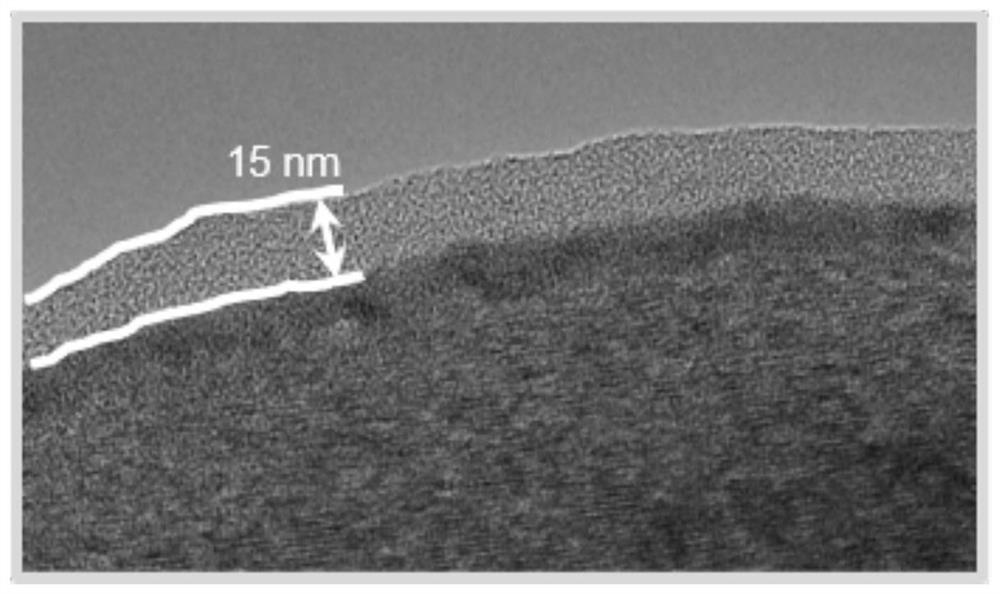

[0060] Dissolve 0.52g of cobalt nitrate hexahydrate in 200mL of absolute ethanol solution and stir for 2 hours to obtain solution A; dissolve 0.59g of sodium borohydride in 200mL of absolute ethanol solution and stir for 2 hours to obtain solution B; The base cathode material was added to solution A and stirred for 3 hours to obtain solution C; during the stirring process, argon gas was continuously introduced to fill the reaction vessel with argon, and solution B was slowly added to solution C through a constant flow pump at a feed rate of 1mL / min, after feeding, keep stirring for 12 hours, and keep ventilating during the stirring process; after stirring, filter and wash 3 times with absolute ethanol; then dry in a vacuum oven at 100°C for 12 hours to obtain coated modified Lithium-rich manganese-based cathode material, named CB-LRM.

[0061] After testing, the structure of the cladding layer i...

Embodiment 2

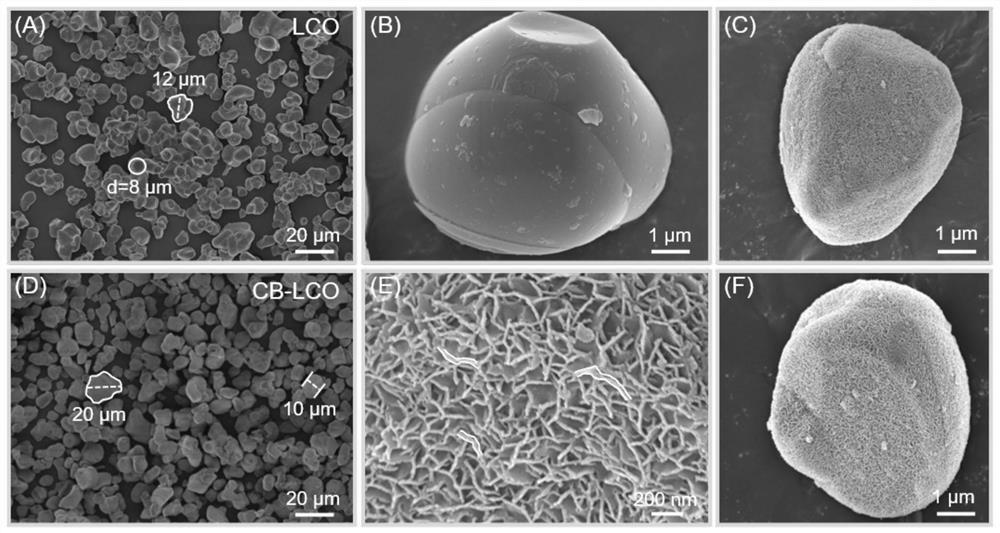

[0065] A preparation method of an electrode material, comprising the steps of:

[0066] Dissolve 0.52g of cobalt nitrate hexahydrate in 200mL of absolute ethanol solution and stir for 2 hours to obtain solution A; dissolve 0.59g of sodium borohydride in 200mL of absolute ethanol solution and stir for 2 hours to obtain solution B; The base cathode material was added to solution A and stirred for 3 hours to obtain solution C; during the stirring process, argon gas was continuously introduced to fill the reaction vessel with argon, and solution B was slowly added to solution C through a constant flow pump at a feed rate of 1mL / min, after feeding, keep stirring for 2 hours, and keep ventilating during the stirring process; after stirring, use absolute ethanol to filter and wash 3 times; then put it in a vacuum drying oven at 100°C for 12 hours to obtain coated modified Lithium-rich manganese-based cathode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com