GaN-based hot electron transistor on self-supporting substrate and preparation method of GaN-based hot electron transistor

A technology of self-supporting substrates and thermal electrons, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of failure to realize common emitter operation of devices, achieve large collector current, good working performance, The effect of high breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

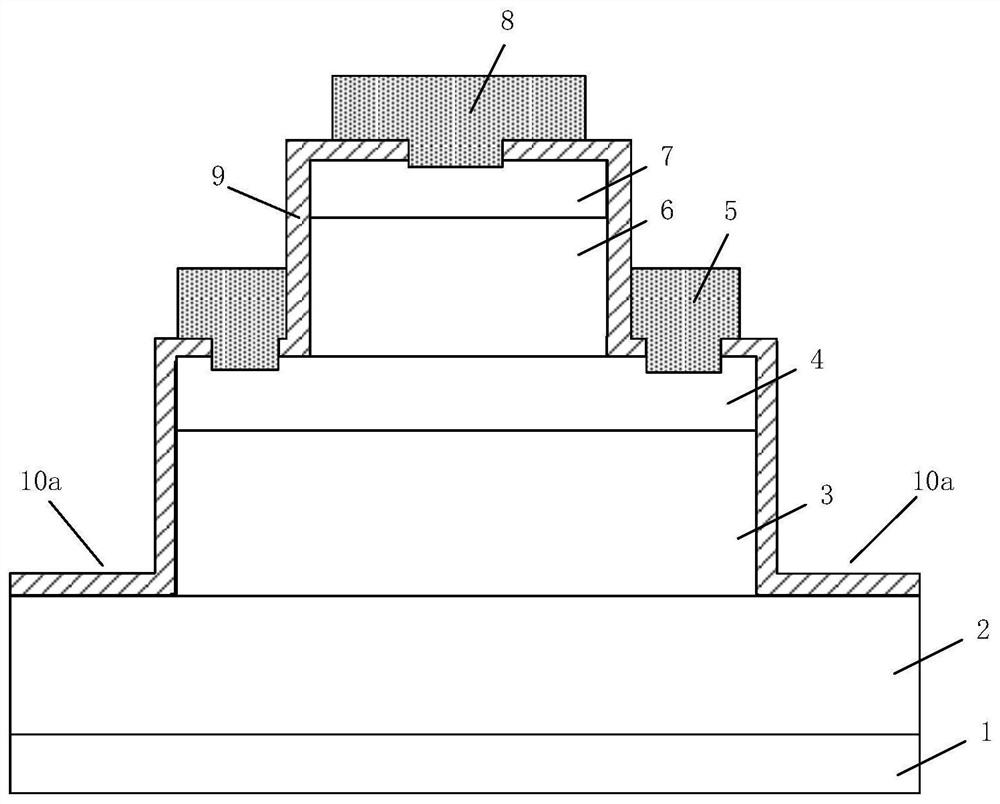

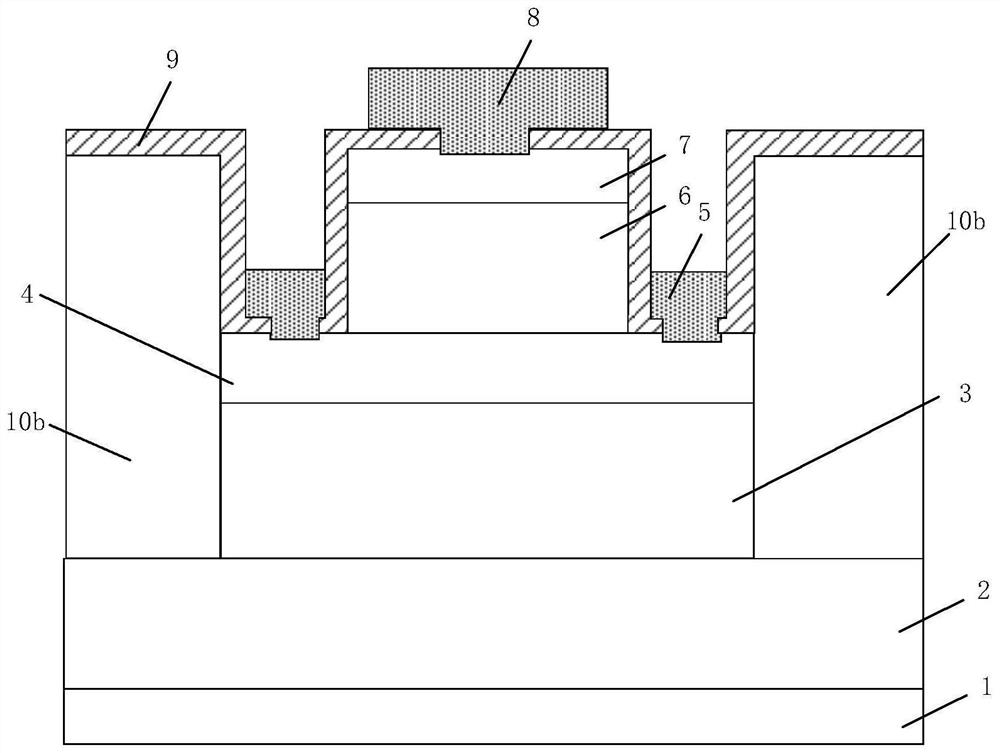

[0042] See figure 1 and figure 2 , figure 1 A schematic structural diagram of a GaN-based thermionic transistor on a self-supporting substrate provided by an embodiment of the present invention, figure 2 A schematic structural diagram of another GaN-based thermionic transistor on a self-supporting substrate provided in an embodiment of the present invention.

[0043] The GaN-based thermionic transistor device is a unipolar vertical structure, including a collector 1, a GaN self-supporting substrate 2, Al y Ga 1-y N collector 3, GaN base 4, base 5, Al x Ga 1-x N emitter region 6 , n+GaN cap layer 7 , emitter 8 and passivation layer 9 .

[0044] Among them, collector 1, GaN free-standing substrate 2, Al y Ga 1-y N collector region 3, GaN base region 4, Al x Ga 1-x The N emitter region 6 and the n+GaN cap layer 7 are stacked in sequence, and the Al x Ga 1-x The N emitter region 6 and the n+GaN cap layer 7 form a mesa structure; the passivation layer 9 is located in ...

Embodiment 2

[0059] On the basis of Example 1, please refer to Figure 4 , Figure 4 A schematic flowchart of a method for fabricating a GaN-based thermionic transistor on a self-supporting substrate provided in an embodiment of the present invention.

[0060] In this embodiment, GaN self-supporting substrates 2 and Al that are stacked sequentially from bottom to top are selected.y Ga 1-y N collector region 3, GaN base region 4, Al x Ga 1-x The structure of the N emitter region 6 and the n+GaN cap layer 7 serves as an epitaxial substrate.

[0061] Specifically, the preparation method of the GaN-based thermionic transistor on the self-supporting substrate comprises the steps of:

[0062] S1. Fabricating an electrical isolation structure for the active region of the device on an epitaxial substrate.

[0063] S11 , photolithography the electrical isolation region of the active region on the n+GaN cap layer 7 .

[0064] S12, using the inductively coupled plasma etching process ICP to seq...

Embodiment 3

[0085] On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a GaN-based thermionic transistor on a self-supporting substrate and a preparation method thereof, please refer to Figures 5a-5g , Figures 5a-5g A process schematic diagram of a method for fabricating a GaN-based thermionic transistor on a self-supporting substrate provided in an embodiment of the present invention.

[0086] The GaN-based thermionic transistor includes a collector 1, a GaN free-standing substrate 2, Al y Ga 1-y N collector 3, GaN base 4, base 5, Al x Ga 1-x N emitter 6, n+GaN cap layer 7, emitter 8 and passivation layer 9, such as Figure 5a shown. For the specific structure of the device, please refer to Embodiment 1, which will not be repeated in this embodiment.

[0087] Specifically, the GaN-based thermionic transistor is selected from the collector electrode 1, the GaN self-supporting substrate 2, the Al y Ga 1-y N collector region 3, GaN base region 4, Al x Ga 1-x ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com