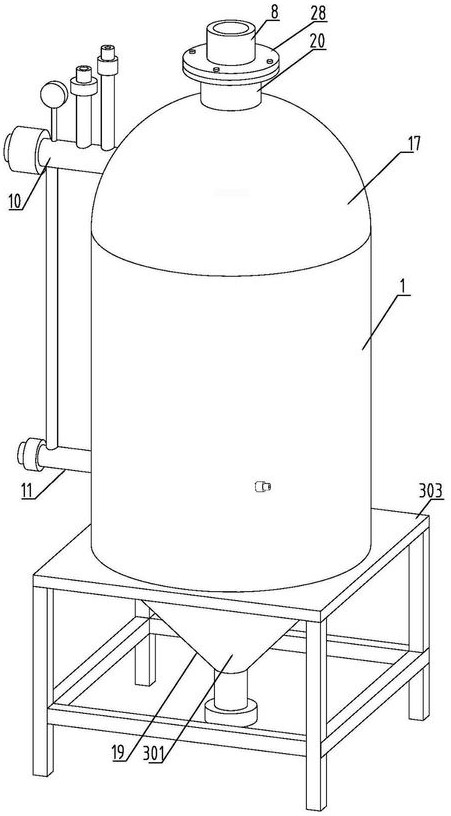

Furnace top gas micro powder recovery pretreatment and heat energy recovery device

A technology of micropowder recovery and heat energy recovery, applied in waste heat treatment, furnaces, furnace components, etc., to achieve the effects of long life, overcoming easy blockage, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

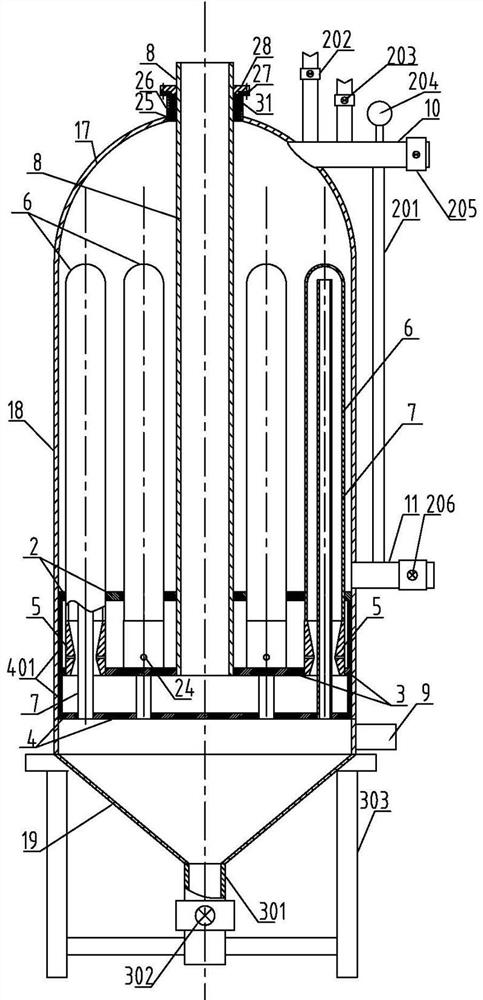

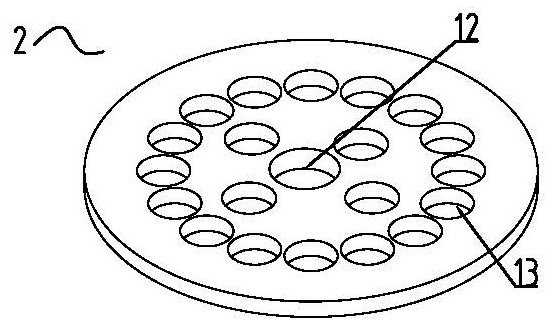

[0026] Embodiment 1: The temperature of the top gas used in the ferrosilicon alloy smelting furnace of the present invention is relatively high (the temperature is about 450°C), and the dust content of the fine powder in the gas is about 80~150g / m3 low 3 Before operation, prepare the above-mentioned parts and connect and assemble the parts. The inner diameter of the hot gas main pipe 8 is 350 mm, the total height of the cylindrical shell part 1 is 6 meters, and the total height of the cylindrical shell 18 is 4 meters. The inner diameter of 18 is 2.8 meters, the length of the heat exchange branch pipe 6 is 3.2 meters, and the inner diameter of the heat exchange branch pipe 6 is 25mm. The external air valve is connected to the external bag filter, the water supply pipe 11 and the water supply valve 205 are connected to the external water supply system, and the external water supply system is integrated with the float level gauge 201 and the steam release valve 203 Cooperate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com