A kind of intelligent sunshade material and its preparation method and application

An intelligent and high-quality technology, which is applied in the field of intelligent sunshade materials and its preparation, can solve the problems of poor weather resistance, impact on sight, poor permeability, etc., and achieve high UV resistance, good film formation and adhesion, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

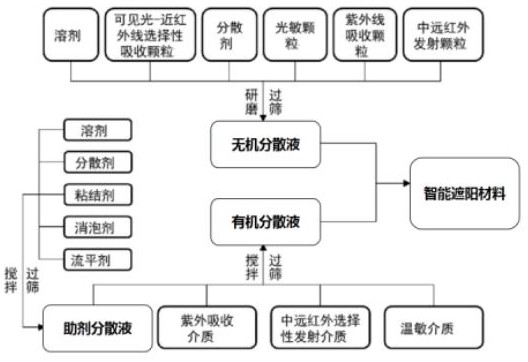

[0033] The intelligent sunshade material is prepared by the following steps, and the process flow is as attached figure 1 shown:

[0034] (1) 72 parts by mass of solvent, 25 parts by mass of visible light-near infrared selective absorbing particles, 1 part by mass of dispersant, 0.5 part by mass of photosensitive particles, 0.8 part by mass of ultraviolet absorbing particles, 2 parts by mass of COSCO The infrared emitting particles were added to a sand mill and ground for 6 hours, and after passing through a 300-mesh sieve, an inorganic dispersion was obtained. Wherein, the solvent is composed of 70 parts by mass of deionized water, 25 parts by mass of ethanol and 5 parts by mass of isopropanol; the visible light-near infrared selective absorption particles are cesium tungstate with a D50 particle size of 50 nanometers; the dispersant is Silane coupling agent KH-570; the photosensitive particles are triclinic tungsten trioxide with a D50 particle size of 20 nm; the ultraviole...

Embodiment 2

[0039] The intelligent sunshade material is prepared by the following steps, and the process flow is as attached figure 1 shown:

[0040] (1) 60 parts by mass of solvent, 20 parts by mass of visible light-near infrared selective absorbing particles, 2 parts by mass of dispersant, 0.3 parts by mass of photosensitive particles, 0.5 parts by mass of ultraviolet absorbing particles, 5 parts by mass of COSCO The infrared emitting particles were added to a sand mill and ground for 12 hours, and after passing through a 300-mesh sieve, an inorganic dispersion was obtained. Among them, the solvent is composed of 60 parts by mass of deionized water, 30 parts by mass of ethanol and 10 parts by mass of isopropanol; the visible light-near infrared selective absorption particles are 10% antimony doped with D50 particle size of 30 nanometers. The dispersing agent is tetramethyldecynediol; the photosensitive particles are orthorhombic molybdenum trioxide with a D50 particle size of 18 nm; th...

Embodiment 3

[0045] The intelligent sunshade material is prepared by the following steps, and the process flow is as attached figure 1 shown:

[0046] (1) 88 parts by mass of solvent, 10 parts by mass of visible light-near infrared selective absorption particles, 0.7 parts by mass of dispersant, 0.3 parts by mass of photosensitive particles, 0.2 parts by mass of ultraviolet absorbing particles, 5 parts by mass of COSCO The infrared emitting particles were added to a sand mill and ground for 3 hours, and after passing through a 300-mesh sieve, an inorganic dispersion was obtained. Among them, the solvent is composed of 80 parts by mass of deionized water, 15 parts by mass of ethanol and 5 parts by mass of isopropanol; the visible light-near infrared selective absorption particles are 10% indium doped with D50 particle size of 20 nanometers. Tin dioxide; dispersant is tetramethyldecynediol; photosensitive particles are silver bromide with D50 particle size of 500 nm; ultraviolet absorbing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com