CPVC fire-fighting pipe and preparation method thereof

A technology of CPVC resin and fire-fighting pipe, applied in the field of CPVC fire-fighting pipe and its preparation, can solve the problems of low Vicat softening point, high torque, and low flame-retardant performance of CPVC fire-fighting pipe, achieve good market prospects, improve processing performance, The effect of reducing the processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

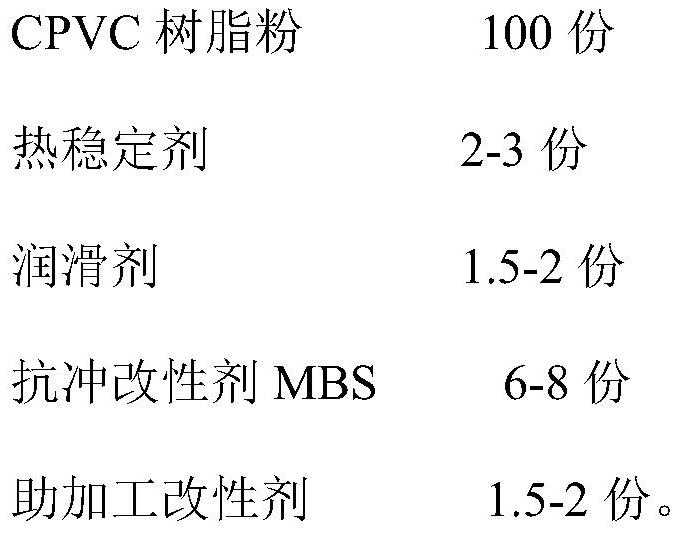

[0043] CPVC fire-fighting pipes, in parts by weight, include the following components:

[0044]

[0045]

[0046] During the preparation of the CPVC fire pipe, the mixture was heated from room temperature to 125°C by self-friction within 10 minutes, and then lowered to 45°C.

[0047] The conical twin-screw extruder adopts zone temperature control, the temperature of the first zone is 170°C, the temperature of the second zone is 190°C, the temperature of the third zone is 193°C, and the temperature of the fourth zone is 190°C.

[0048] The traction speed of the material after being extruded from the conical twin-screw extruder is 2m / min.

Embodiment 2

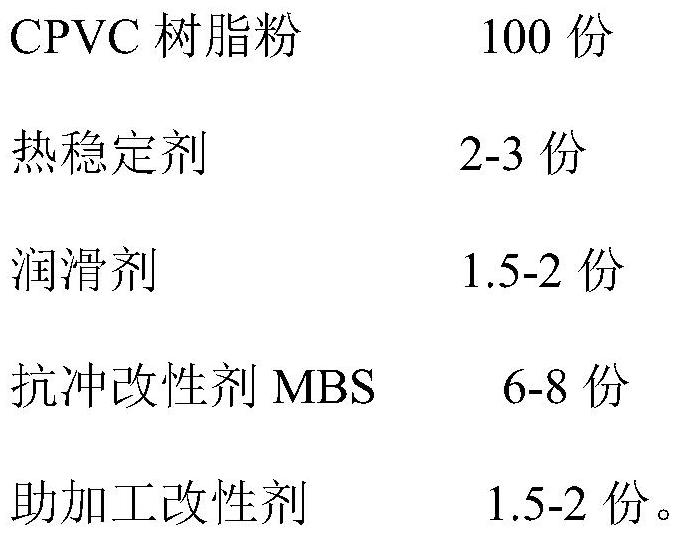

[0050] CPVC fire-fighting pipes, in parts by weight, include the following components:

[0051]

[0052] During the preparation of the CPVC fire pipe, the mixture was heated from room temperature to 128°C by self-friction within 12 minutes, and then lowered to 48°C.

[0053]The conical twin-screw extruder adopts zone temperature control, the temperature of the first zone is 172°C, the temperature of the second zone is 193°C, the temperature of the third zone is 195°C, and the temperature of the fourth zone is 192°C.

[0054] The pulling speed of the material after being extruded from the conical twin-screw extruder is 2.5m / min.

Embodiment 3

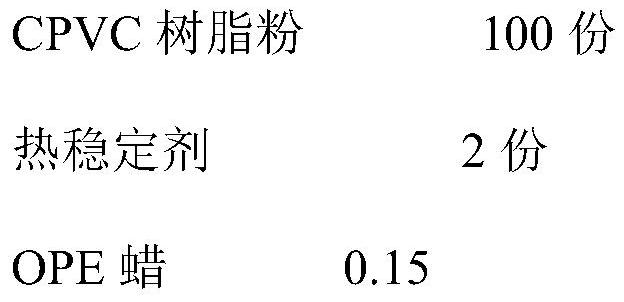

[0056] CPVC fire-fighting pipes, in parts by weight, include the following components:

[0057]

[0058] During the preparation of the CPVC fire pipe, the mixture was heated from room temperature to 130°C by self-friction within 15 minutes, and then lowered to 50°C.

[0059] The conical twin-screw extruder adopts zone temperature control, the temperature of the first zone is 175°C, the temperature of the second zone is 195°C, the temperature of the third zone is 198°C, and the temperature of the fourth zone is 195°C.

[0060] The pulling speed of the material after being extruded from the conical twin-screw extruder is 3m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com