Carbon material wide-temperature-range anti-oxidation anti-scouring multiphase ceramic coating and preparation method thereof

A technology of multiphase ceramics and wide temperature range, which is applied to the wide temperature range anti-oxidation and anti-scouring multiphase ceramic coating of carbon materials and its preparation field, can solve the problem of short anti-oxidation life and temperature range, many coating defects and complex process and other problems, to achieve the effect of low cost, large area and dense coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

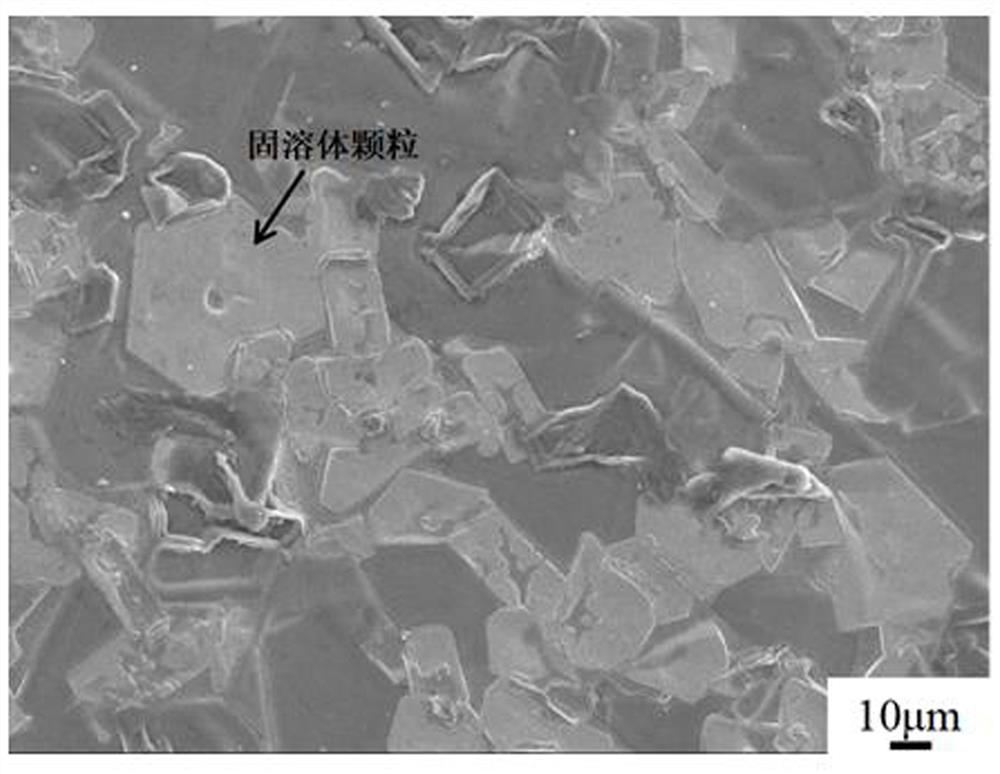

Image

Examples

preparation example Construction

[0041] A method for preparing a carbon material wide temperature range anti-oxidation and anti-scouring composite ceramic coating, comprising the following preparation steps:

[0042] Step 1. Make the density 1.78-1.82 g / cm 3 The graphite block is cut into a certain size, then polished to remove edges and corners, the treated graphite block is cleaned with deionized water, and then dried for later use to obtain a graphite matrix.

[0043] Step 2, powder SiC, B in turn 4 C, Hf, Zr, and Ta are added to the phenolic resin aqueous solution and mixed to form a slurry, and stirred to form a uniformly dispersed slurry without particle agglomeration.

[0044] Step 3. Immerse the graphite substrate in the stirring slurry for 2~5s, then stop stirring and take out the graphite substrate, put it on the polyurethane foam to dry naturally, put the dried graphite substrate in an oven at 120~180℃ to make the phenolic The resin undergoes a cross-linking reaction, and the reaction time is 15-...

Embodiment 1

[0052] High-strength graphite (with a density of 1.79 g / cm 3 ) was cut into a cube with a side length of 10 mm and a cylinder with a diameter of 18 mm and a height of 10 mm, wherein the cube was the oxidation test sample, and the cylinder was the ablation test sample; the graphite block was polished with 400# silicon carbide sandpaper to remove the corners, Then clean it with deionized water, and dry it in an oven at 150°C for 2 hours;

[0053] Prepare water-soluble phenolic resin and deionized water according to the mass ratio of 1:3 to prepare a phenolic resin solution, and then add B 4 C. Hafnium (Hf), zirconium (Zr), tantalum (Ta) and SiC powders are added to the magnetically stirred phenolic resin solution in sequence, and the mass ratio of the total powder mass to the phenolic resin solution is 6:4 (total powder mass The mass accounts for 60% of the total mass of the slurry), and the molar ratio of hafnium (Hf), zirconium (Zr), tantalum (Ta), and boron carbide is 6:6:8:...

Embodiment 2

[0058] High-strength graphite (with a density of 1.80 g / cm 3 ) was cut into a cube with a side length of 10 mm and a height of 5 mm, and a cylinder with a diameter of 29 mm and a height of 10 mm, wherein the cube was an oxidation test sample, and the cylinder was an ablation test sample; the graphite block was polished with 600# silicon carbide sandpaper , remove the edges and corners, then clean it with deionized water, and dry it in an oven at 150°C for 2 hours;

[0059] Prepare water-soluble phenolic resin and deionized water according to the mass ratio of 2:5 to prepare phenolic resin solution, and then add B 4 C. Hafnium (Hf), zirconium (Zr), tantalum (Ta) and SiC powders were added to the magnetically stirred phenolic resin solution in sequence, the total mass of the powder accounted for 55% of the total mass of the slurry, hafnium (Hf), The molar ratio of zirconium (Zr), tantalum (Ta), and boron carbide is 8:6:6:1.

[0060] Immerse the graphite matrix in the stirred s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com