Welding fixture for water box body of steam turbine generator unit and application method of welding fixture

A technology for a steam turbine generator set and a welding fixture, which is applied to welding accessories and other directions, can solve the problem that it is difficult to meet the implementation of automatic argon arc welding, it is difficult to adapt to the installation limit of water box bodies of different structures, and it is difficult to achieve centering, leveling, and limiting. , locking function and other issues, to achieve the effect of small occupied space, convenient and accurate coaxial and concentric fixation, easy processing and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

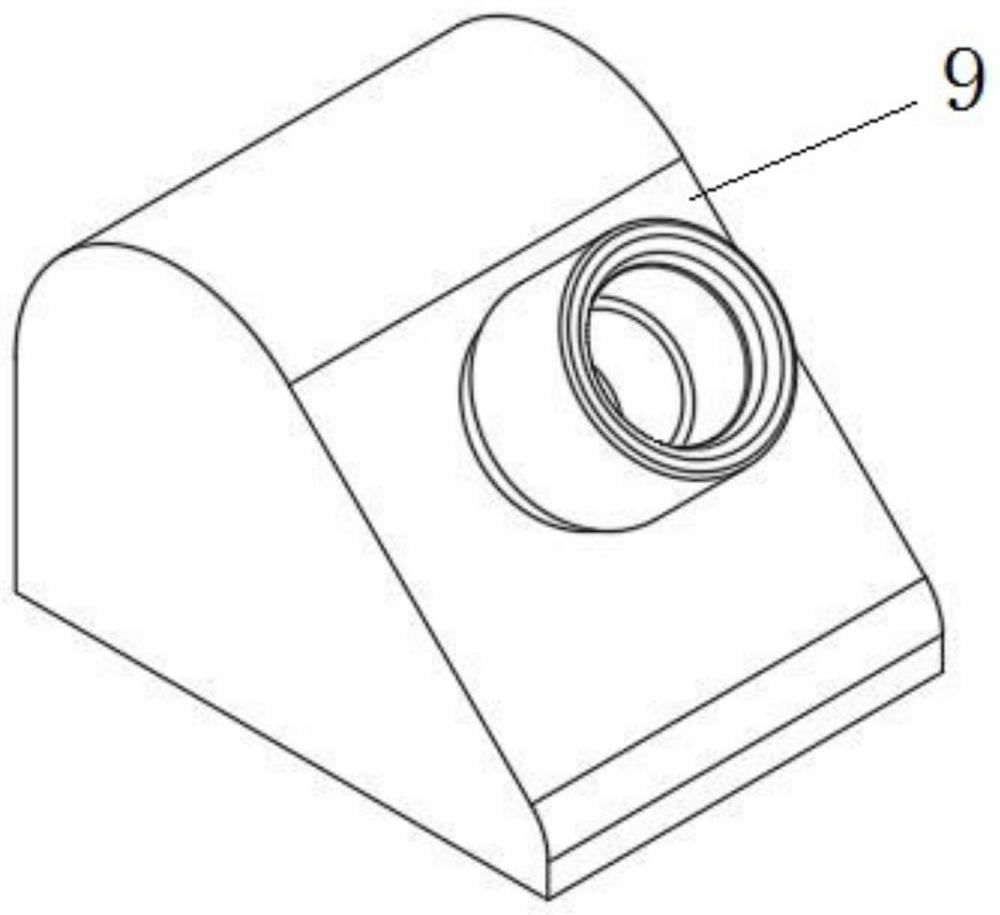

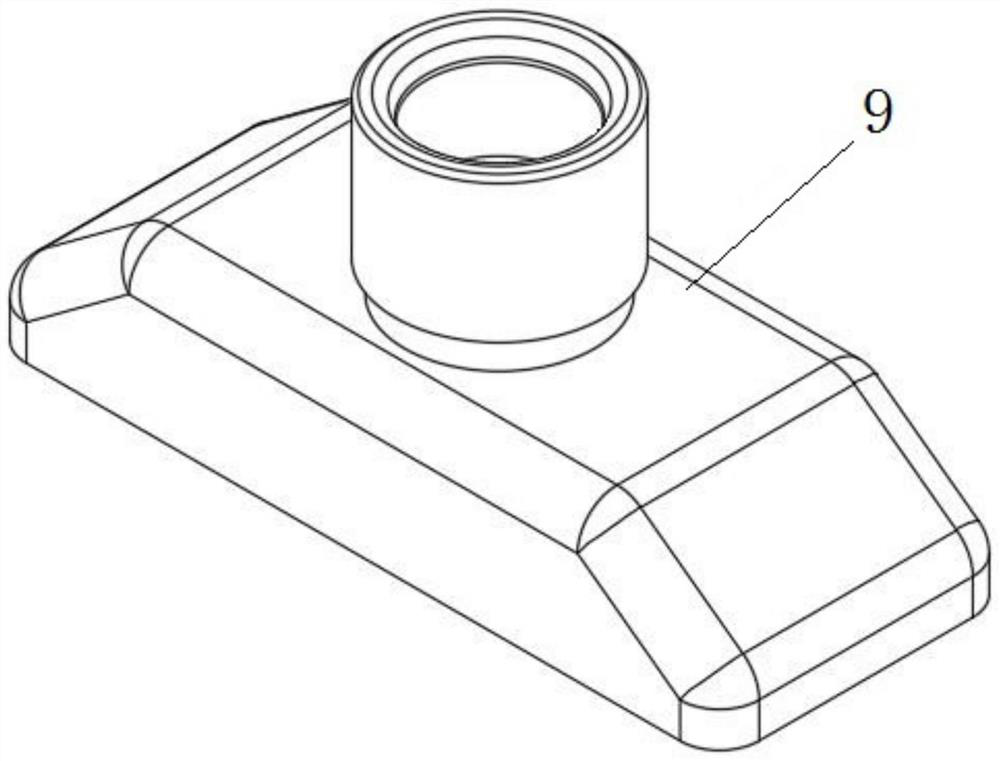

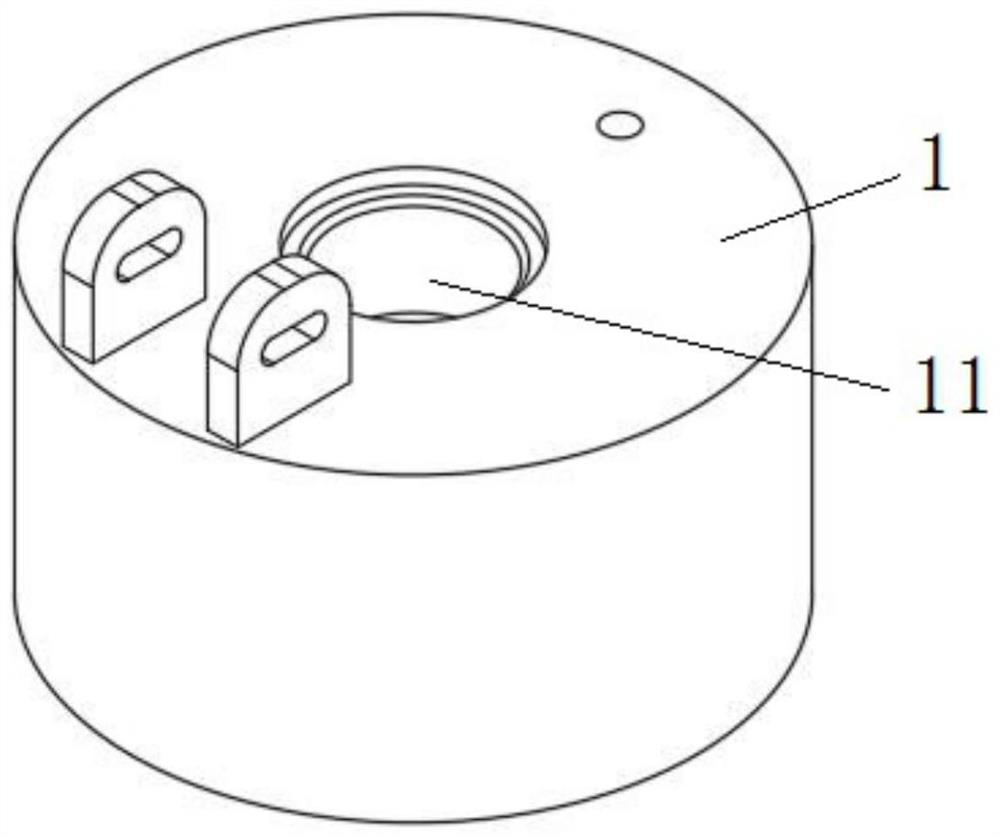

[0054] Such as Figure 1 to Figure 11 As shown, a welding fixture for the water box body of a steam turbine generator set includes a rotary base 1, a positioning pin sleeve 2, a positioning rod 3, an adjustment plate 6, a height adjustment member 7, and a positioning device. The rotary base 1 is provided with Base positioning hole 11, the positioning pin sleeve 2 is nested in the base positioning hole 11, the positioning pin sleeve 2 is sleeved outside the bottom end of the positioning rod 3, the rotary base 1 and the adjusting plate One end of 6 is rotationally connected, and the height adjusting member 7 is connected to the other end of the adjusting plate 6, and the height adjusting member 7 can adjust the vertical height between the other end of the adjusting plate 6 and the rotary base 1 , the positioning device is used to limit the water box body 9 .

[0055] To use, the following steps can be taken:

[0056] S1, connecting the rotary base 1 with the chuck of the argon...

Embodiment 2

[0074] Such as Figure 1 to Figure 11 As shown, as a further optimization of Embodiment 1, this embodiment includes all the technical features of Embodiment 1. In addition, this embodiment also includes the following technical features:

[0075] As a preferred technical solution, the positioning rod 3 is provided with a positioning external thread 31 , the positioning device is a locking nut 4 , and the locking nut 4 cooperates with the positioning external thread 31 .

[0076] The locking nut 4, the positioning external thread 31, and the support of the adjusting plate 6 to the water box body 9 limit the position of the water box body 9. The structure is simple, the operation is convenient and efficient, and it is convenient for installation and disassembly.

[0077] As a preferred technical solution, a locking washer 5 is also included, and the locking washer 5 cooperates with the locking nut 4 and the positioning external thread 31 .

[0078] The setting of the locking gas...

Embodiment 3

[0080] Such as Figure 1 to Figure 11 As shown, on the basis of Embodiment 1 and Embodiment 2, this embodiment provides a method for using a welding jig for a water box body of a turbogenerator set.

[0081] A method for using a welding jig for a water box body of a turbogenerator set, comprising the following steps:

[0082] S1, connecting the rotary base 1 with the chuck of the argon arc welding machine, so that the center of the positioning hole 11 of the base is consistent with the center of rotation of the chuck;

[0083] S2, adjusting the relative positional relationship between the positioning rod 3 and the base positioning hole 11, so that the positioning rod 3 and the base positioning hole 11 are coaxial and concentrically fixed;

[0084] S3, setting the water box body 9 outside the positioning rod 3;

[0085] S4, using the positioning device to limit the position of the water box body 9 .

[0086] In the present invention, the positioning pin sleeve 2 is nested in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com