Making method of ginger wafer biscuit capable of regulating intestinal flora

A technology for regulating intestinal flora and ginger, applied in the direction of microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve the problem of reducing the number of beneficial bacteria and the crazy growth of harmful bacteria, etc. problem, achieve the effect of prolonging the shelf life and lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

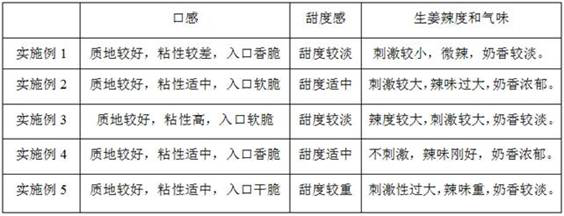

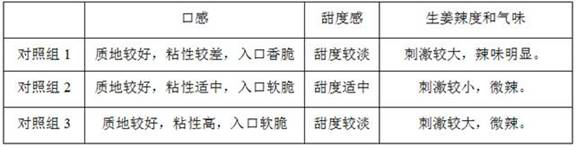

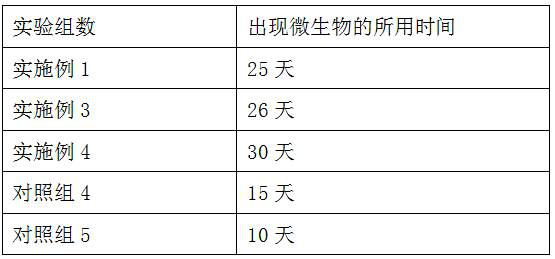

Examples

Embodiment 1

[0029] (1) Preparation of ginger extract: Microwave-assisted three-phase partitioning (TPP) combined extraction was used to put fresh ginger into a high-pressure homogenizing emulsifier APV-1000, and an equal volume of phosphate buffer solution with pH=8 was added. After homogenization, filter the residue to obtain rough extraction. Ammonium sulfate was added to the crude extract to 40% saturation, and tert-butanol was added in a volume ratio of 1:1.

[0030] (2) Put the mixture into a microwave instrument (AL-IMC1 intelligent microwave synthesis / extraction instrument), set the power at 150W for 5 minutes, let it stand for 10 minutes, and centrifuge at 4000r / min for 10 minutes to obtain three phases. The upper organic phase was collected, filtered, and evaporated to remove the tert-butanol solvent in a vacuum evaporator at 40°C to obtain ginger oleoresin. Remove the lower water phase, take the middle phase as a turbid liquid, adjust the pH to 5 to form a precipitate, centrifu...

Embodiment 2

[0035] (1) Preparation of ginger extract: Microwave-assisted three-phase partitioning (TPP) combined extraction was used to put fresh ginger into a high-pressure homogenizing emulsifier APV-1000, and an equal volume of phosphate buffer solution with pH=8 was added. After homogenization, filter the residue to obtain rough extraction. Ammonium sulfate was added to the crude extract to 50% saturation, and tert-butanol was added in a volume ratio of 1:1.

[0036](2) Put the mixture into a microwave instrument (AL-IMC1 Intelligent Microwave Synthesis / Extraction Instrument), set the power to 100W for 10 minutes, let it stand for 10 minutes, and centrifuge at 4000r / min for 10 minutes to obtain three phases. The upper organic phase was collected, filtered, and evaporated to remove the tert-butanol solvent in a vacuum evaporator at 40°C to obtain ginger oleoresin. Remove the lower water phase, take the middle phase as a turbid liquid, adjust the pH to 5 to form a precipitate, centrifu...

Embodiment 3

[0041] (1) Preparation of ginger extract: Microwave-assisted three-phase partitioning (TPP) combined extraction was used to put fresh ginger into a high-pressure homogenizing emulsifier APV-1000, and an equal volume of phosphate buffer solution with pH=8 was added. After homogenization, filter the residue to obtain rough extraction. Ammonium sulfate was added to the crude extract to 60% saturation, and tert-butanol was added in a volume ratio of 1:1.

[0042] (2) Put the mixture into a microwave instrument (AL-IMC1 Intelligent Microwave Synthesis / Extraction Instrument), power 300W for 5 minutes, let it stand for 10 minutes, and centrifuge at 4000r / min for 10 minutes to obtain three phases. The upper organic phase was collected, filtered, and evaporated to remove the tert-butanol solvent in a vacuum evaporator at 40°C to obtain ginger oleoresin. Remove the lower water phase, take the middle phase as a turbid liquid, adjust the pH to 5 to form a precipitate, centrifuge at 4000r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com