Method for removing zinc from extraction solution and application of rare earth saponification wastewater

A technology for saponifying wastewater and extracting liquid of rare earth, which is applied in the field of zinc removal, and achieves the effects of good process stability, high industrial practical value and convenient industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

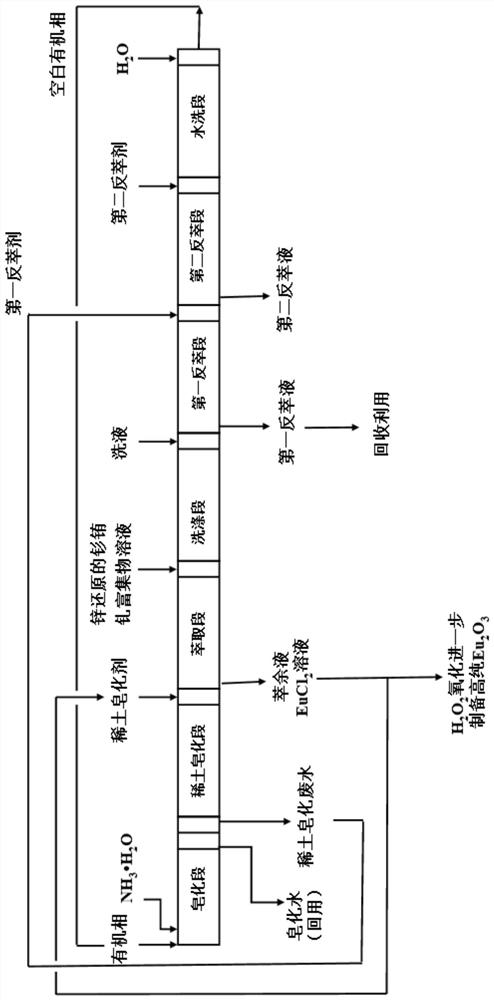

Method used

Image

Examples

Embodiment 1~3

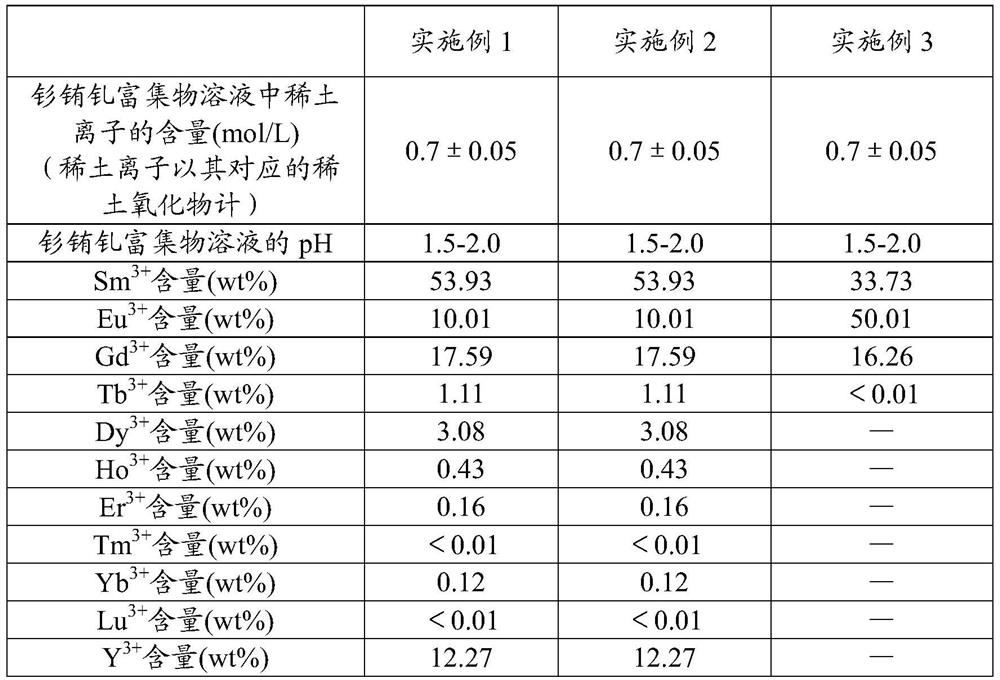

[0091] The samarium europium gadolinium enrichment solution is reduced by using zinc powder to obtain the zinc-reduced samarium europium gadolinium enrichment solution. In the zinc-reduced samarium-europium-gadolinium enrichment solution, the reduction rate Eu 2+ / Eu 3+ ≥99%. The parameters of the samarium europium gadolinium enrichment solution are shown in Table 1.

[0092] Saponification stage: the organic phase is P 507 and kerosene mixture, P in the organic phase 507 The content is 1.5mol / L. The organic phase was contacted with aqueous ammonia having a concentration of 9 mol / L to obtain a saponified organic phase. The saponification method is continuous co-current.

[0093] Rare earth saponification section: Use part of the raffinate produced in the extraction section as a rare earth saponification agent, and contact the saponified organic phase with the rare earth saponification agent to obtain the rare earth saponification organic phase and rare earth saponificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com