Method for efficiently recycling salt-containing sewage by magnetic synergistic electrodialysis

An electrodialysis and recycling technology, which is applied in the fields of magnetic field/electric field water/sewage treatment, chemical instruments and methods, separation methods, etc. Large and other problems, to achieve the effect of shortening the process time, realizing the recycling of water resources, reducing the quantity and the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

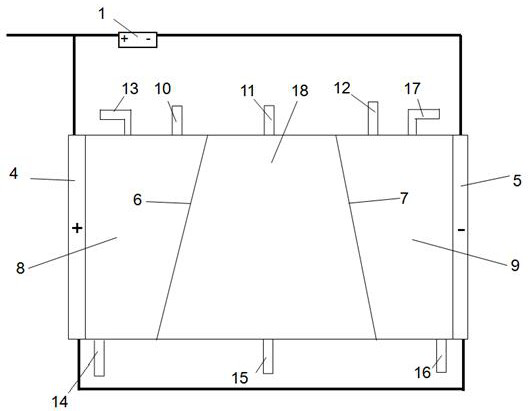

[0025] Example 1: The high-efficiency resource utilization method of magnetic synergy electrodialysis is used for the treatment of saline sewage from a mine in Yunnan. The specific content is as follows:

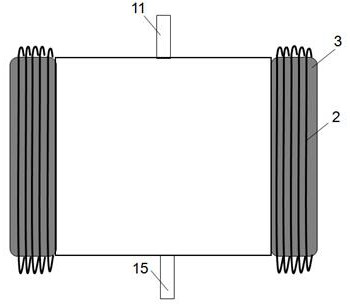

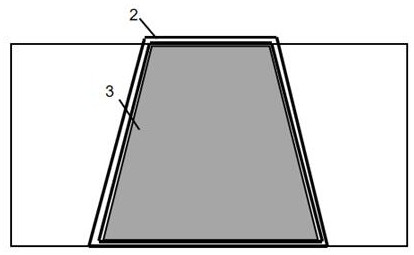

[0026] Such as Figure 1-3As shown, the magnetic synergy electrodialysis device includes a reaction chamber, a magnetic field generator, an anode plate 4, a cathode plate 5, a cation exchange membrane 6, an anion exchange membrane 7, a power supply 1, and the cation exchange membrane 6 and anion exchange membrane 7 are obliquely arranged in the reaction chamber. In the chamber, the reaction chamber is divided into an acid chamber 8, an intermediate chamber 18, and an alkali chamber 9. The anode plate 4 and the cathode plate 5 are respectively arranged on the side walls of the acid chamber and the alkali chamber. The magnetic field generator includes a magnetic coil 2 and a magnetic field conductive plate. 3. Two magnetic field conductive plates 3 are respectively arranged ou...

Embodiment 2

[0032] Embodiment 2: The device structure of this embodiment is the same as Embodiment 1, and the differences are as follows:

[0033] (1) Take 8000mL of saline sewage from a mining factory in Yunnan, with a salt concentration of 230mg / L; the inlet solution of the anode chamber is 0.6mol / L sulfuric acid, and the inlet solution of the cathode chamber is 0.8mol / L sodium hydroxide; the electrodialysis cathode uses 24 cm×24 cm nickel-based alloy electrode (refer to the method in “Preparation and Performance Characterization of Nickel-based Composite Coating”), and the anode is 24 cm×24 cm using CNTs composite electrode (refer to “Polyaniline-modified carbon-based flexible self-supporting Prepared by the method in "Preparation of Supercapacitor Electrode Materials and Research on Electrochemical Properties"); the two electrodes are facing each other with a distance of 8.5 cm;

[0034] The capacity of the electrolytic cell is 30 cm × 24 cm × 24 cm, using polyethyleneimine anion exch...

Embodiment 3

[0038] Embodiment 3: The device structure of this embodiment is the same as Embodiment 1, and the difference is as follows:

[0039] (1) Take 10L of saline sewage from a mining factory in Yunnan, the salt concentration is 230mg / L, the inlet solution of the anode chamber is 0.6mol / L sulfuric acid, and the inlet solution of the cathode chamber is 0.8mol / L sodium hydroxide. Electrodialysis cathode adopts 24cm×24cm titanium-based tin system (Ti / Sb-SnO 2 ) electrode, the anode is a 24cm×24cm PANI electrode; the two electrodes are facing each other with a distance of 8.5 cm;

[0040] The capacity of the electrolytic cell is 30cm×24cm×24cm. The cathode chamber, intermediate chamber and anode chamber are separated by PVDF ion exchange membrane. During the reaction process, the flow rate of the solution in the three chambers is maintained at 0.08m / s. The DC power supply provides a regulated power supply, and the electrodialysis uses a constant current for electrolysis;

[0041] (2) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com