Large and medium-sized equipment frequency conversion-power frequency combined driving system

A combined drive, large and medium-sized technology, applied in the field of frequency conversion, can solve the problems of aluminum electrolytic capacitors such as large volume, capacity drop, and large impedance, and achieve the effects of small loss, small leakage current, and small time constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

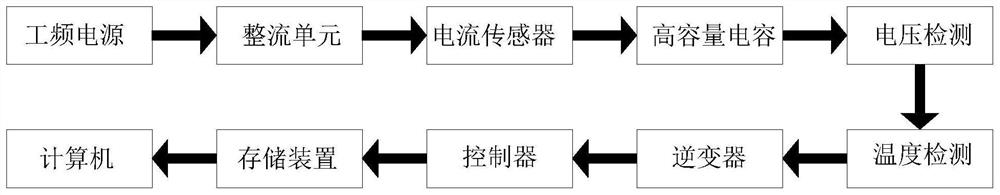

[0027] Example: frequency conversion-power frequency combined drive system for large and medium-sized equipment, such as figure 1 As shown, it includes a power frequency power supply, a rectification unit, a current sensor, a high-capacity capacitor, a voltage detection, a temperature detection, an inverter, a controller, a storage device, a computer; the output end of the power frequency power supply and the input end of the rectification unit connected, the output end of the rectification unit is connected to the input end of the current sensor, the output end of the current sensor is connected to the input end of the high-capacity capacitor, the output end of the high-capacity capacitor is connected to the input end of the voltage detection, and the The output end of the voltage detection is connected to the input end of the temperature detection, the output end of the temperature detection is connected to the input end of the inverter, the output end of the inverter is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com