Charging seat with high-precision centering terminals and motor vehicle

A charging stand, high-precision technology, applied in the direction of electric vehicles, charging stations, vehicle energy storage, etc., can solve problems such as temperature rise between terminals, fire and combustion in the charging system, and excessive contact resistance, so as to reduce the risk of fire and combustion , Improve corrosion resistance and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

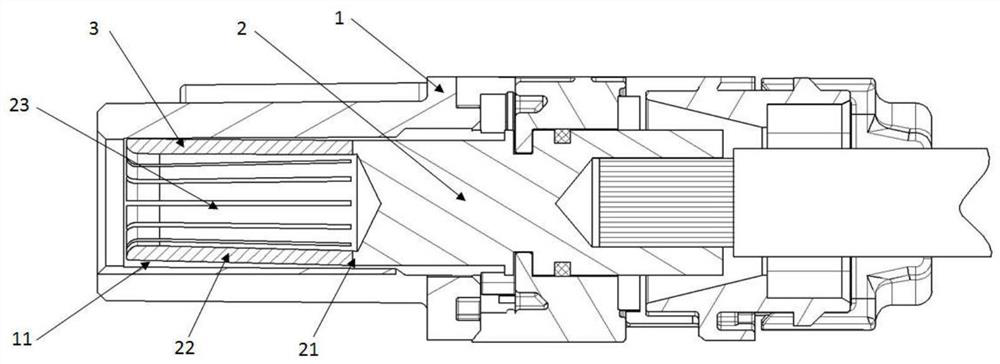

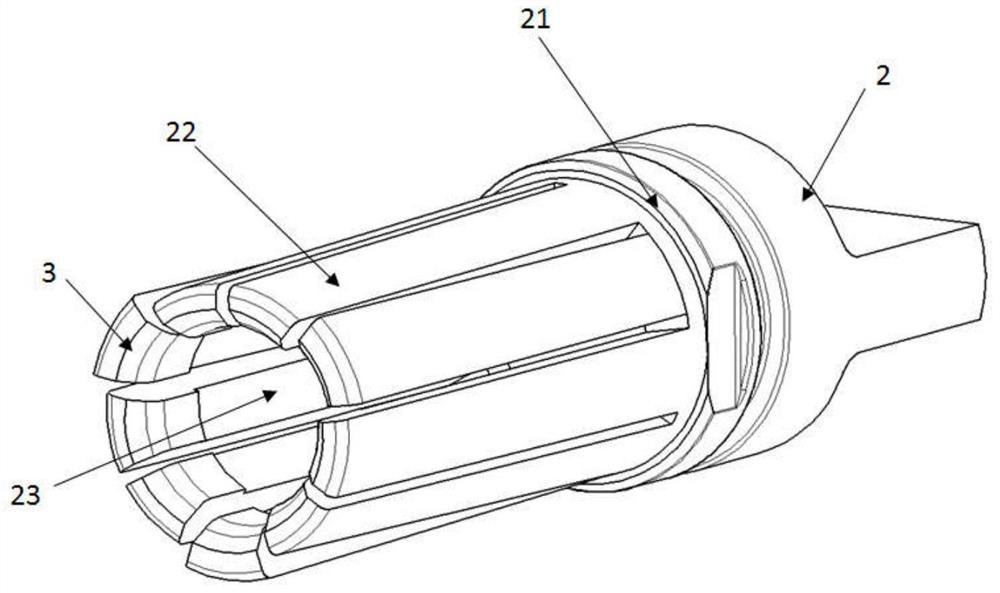

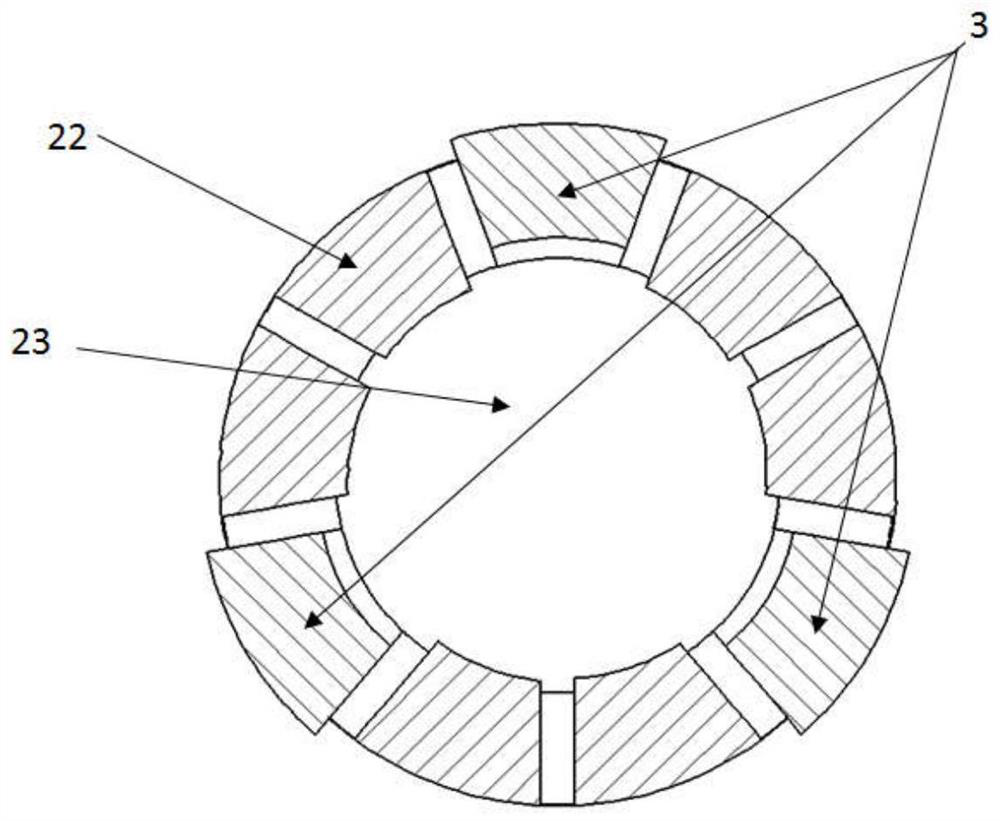

[0077] The present invention provides a charging stand 1 with high-precision centering of terminals, such as Figure 1-Figure 3 As shown, the charging base 1 is provided with a cavity 11 for accommodating the charging terminal 2. There is a gap between the inner peripheral wall of the cavity 11 and the outer peripheral wall of the charging terminal 2, and the supporting elastic piece 3 is arranged in the gap, and the supporting elastic piece 3 is arranged along the circumferential direction of the charging terminal 2. , the supporting elastic piece 3 is configured to limit the deviation of the axis of the charging terminal 2 from the axis of the cavity 11 . In the charging stand 1, the supporting elastic piece 3 is arranged in the circumferential direction of the charging terminal 2, which can support the charging terminal 2 in the center of the cavity of the charging stand 1, so that when the mating terminal is inserted, it can be directly plugged and contacted with the chargi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com