Radioactive comprehensive wastewater treatment method

A technology that integrates waste water and treatment methods, applied in radioactive purification, nuclear engineering, etc., can solve problems such as the reduction of pollutant concentration, and achieve the effect of large treatment capacity, simple process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

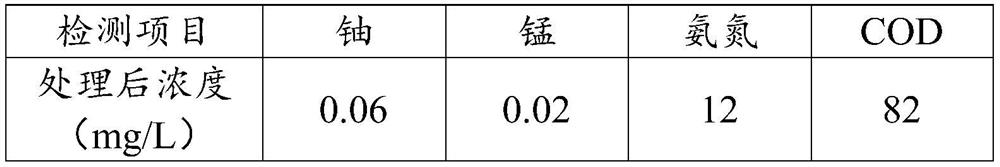

Embodiment 1

[0049] Take the wastewater from a uranium tailings pond and analyze it. Among them, the concentration of uranium is 8mg / L, the concentration of manganese ion is 47.5mg / L, the concentration of inorganic ammonia nitrogen is 378mg / L, the concentration of COD is 210mg / L, and the concentration of chloride ion is 1870mg / L. L.

[0050] Put 2000mL of radioactive comprehensive wastewater into the deuranium sedimentation tank, add 11g of carbide slag with an average particle size of 1mm, stir and react for 0.5h at room temperature, and the pH value is 10. Let it stand for 5h to precipitate the precipitate, and then separate it by filtration.

[0051] Pass the separated wastewater into the electrolytic cell, using Ti / RuO 2 -IrO 2 Mesh titanium base plate is used as the anode plate, stainless steel plate is used as the cathode plate, the distance between the plates is 10cm, and the current density is adjusted to 20mA / cm 2 , treatment 3h.

[0052] The treated wastewater is introduced i...

Embodiment 2

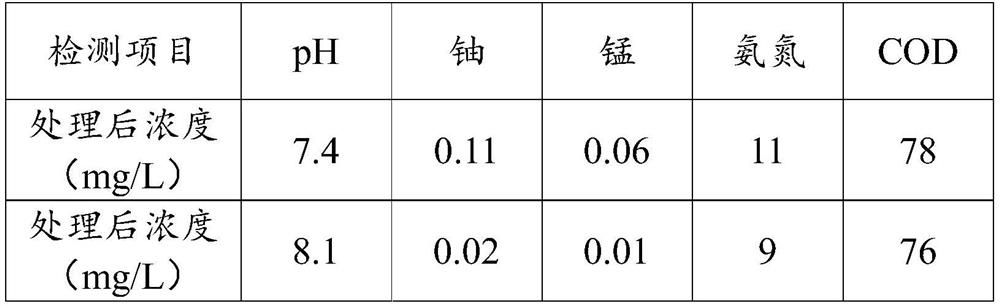

[0056] The radioactive comprehensive wastewater was treated according to the method in Example 1, the only difference being that 9 g and 13 g of carbide slag with an average particle size of 1 mm were added, and after stirring and reacting for 0.5 h at room temperature, the pH values were 9.5 and 11 respectively. Test the pH value, uranium content, manganese ion content, ammonia nitrogen content and COD value of the wastewater to be discharged. The test results are shown in Table 2.

[0057] Table 2:

[0058]

Embodiment 3

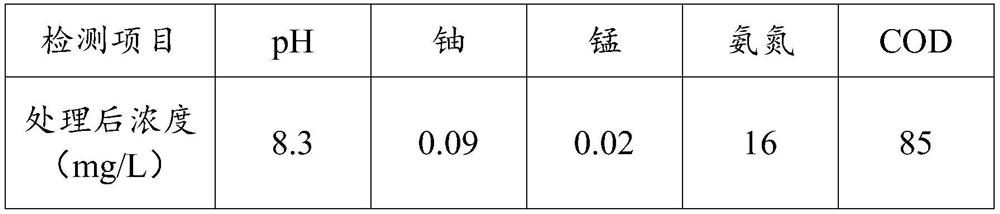

[0060] Process mine wastewater according to the method in Example 1, the difference is only that the current density is 15mA / cm 2 . Test the pH value, uranium content, manganese ion content, ammonia nitrogen content and COD value of the wastewater to be discharged. The test results are shown in Table 3.

[0061] table 3:

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com