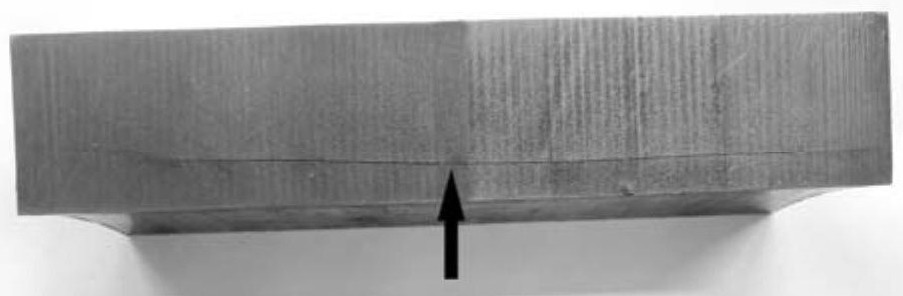

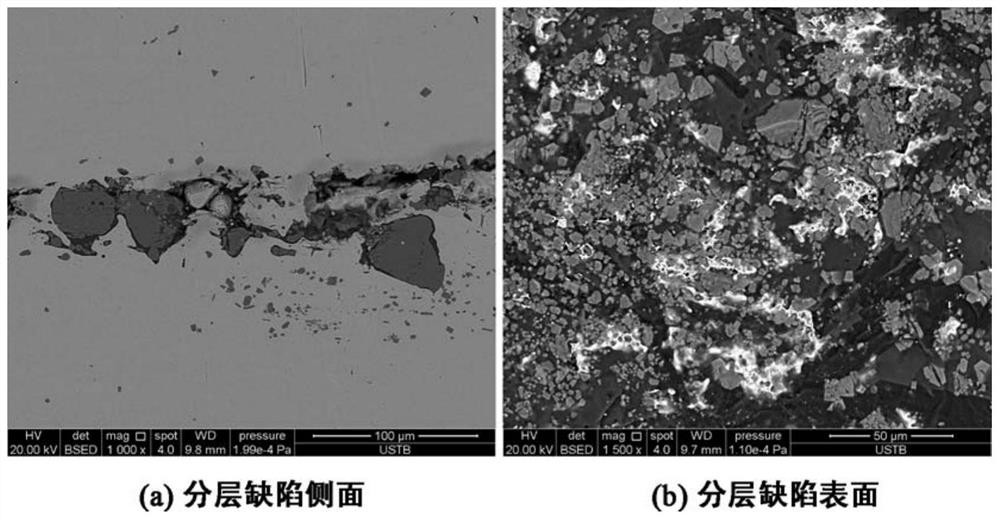

Smelting process for reducing layering defect of TP321 stainless steel seamless tube

A technology of TP321 and delamination defects, which is applied in the smelting process field of reducing delamination defects of TP321 stainless steel seamless pipes, can solve problems such as unstable control, achieve the effects of improving quality, increasing the pass rate of ultrasonic flaw detection, and reducing the total oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] (1) Crude molten steel is provided by the electric arc furnace: the raw materials of the electric arc furnace include scrap steel and returned materials, and the composition of the crude molten steel obtained after melting is shown in Table 2, that is, the composition of the molten steel in the AOD furnace; the composition of the molten steel in the AOD furnace is detected as 1475°C.

[0057] (2) AOD oxygen blowing decarburization: After the molten steel is put into the furnace, add 1500kg of lime, 200kg of magnesium oxide, oxygen-argon mixed blowing for decarburization, and gradually adjust the flow rate of oxygen-argon to reduce the burning of Cr element during the decarburization process. During this period, 800kg of high-carbon ferrochromium and 60kg of electrolytic manganese were added; after decarburization, the composition of molten steel is shown in Table 2.

[0058] (3) AOD ferrosilicon reduction: Add 300kg of lime and 450kg of ferrosilicon to the furnace, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com