Degradable heat-resistant polylactic acid pipe as well as preparation method and application thereof

A polylactic acid and heat-resistant technology, which is applied in the field of degradable heat-resistant polylactic acid pipes and its preparation, can solve the problems of difficult coordination and unification of PLA straws, heat resistance can not maintain toughness, and poor resin compatibility, so as to facilitate subsequent processing , good mechanical properties and short crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

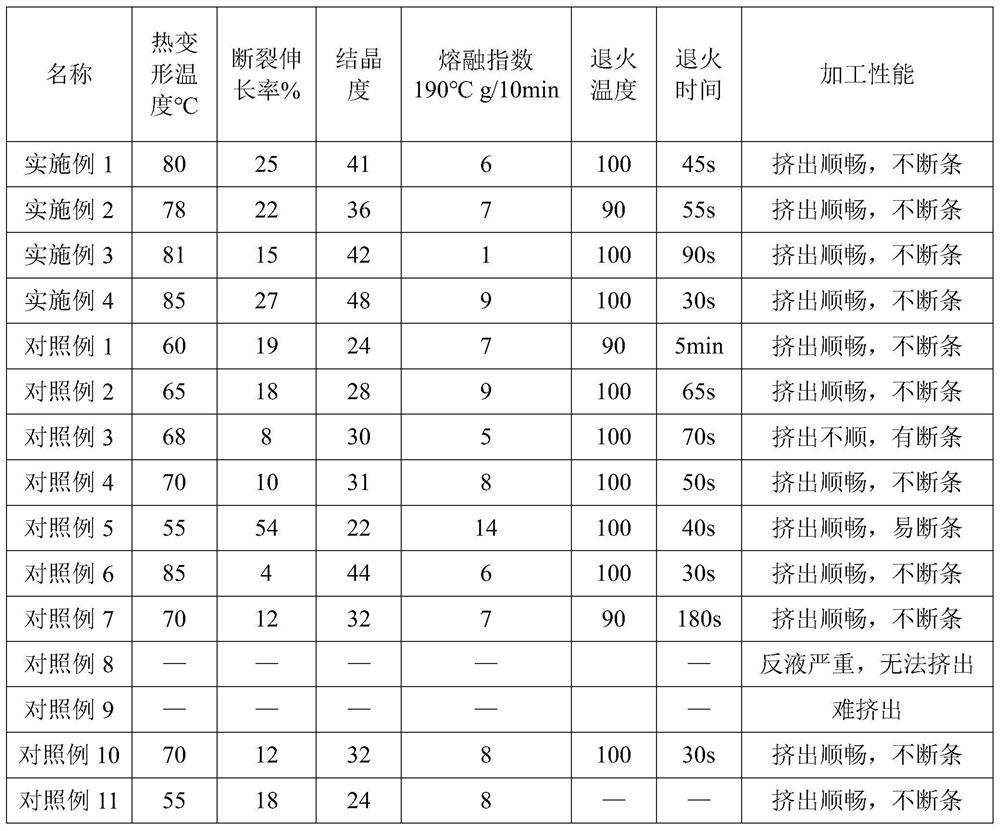

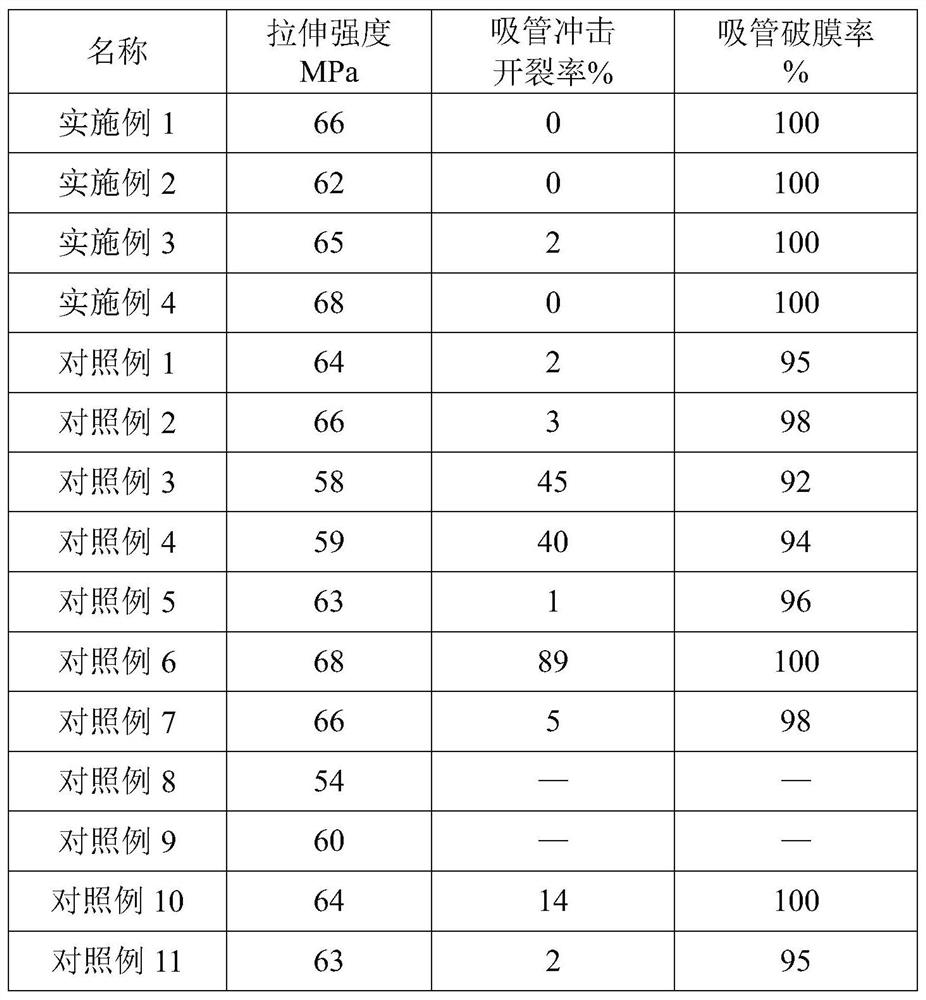

[0030] Another aspect of the embodiments of the present invention also provides a method for preparing any one of the aforementioned degradable heat-resistant polylactic acid pipes, which includes: combining polylactic acid, an inorganic nucleating agent, an organic nucleating agent, and a reactive toughening agent with The micro-crosslinking agent is uniformly mixed, and then the obtained mixed material is melt-blended, extruded and granulated, and then extruded and annealed to obtain a degradable heat-resistant polylactic acid pipe.

[0031] In some more specific embodiments, the temperature of the annealing treatment is 90-110°C, and the time is 30s-90s.

[0032] In some more specific embodiments, the temperature of the melt blending is 170-180°C.

[0033] Polylactic acid has a slow crystallization rate, poor heat resistance, and is hard and brittle, while the straw material requires a certain toughness of the material. In the present invention, the combined use of organic...

Embodiment 1

[0039] 89.7 parts of polylactic acid, 3 parts of inorganic nucleating agent talc powder, 1 part of organic nucleating agent TMC300, reactive toughening agent (composite of 0.5 parts of diethylene glycol diglycidyl ether and 5 parts of PEG6000) and microcross The coupling agent (a compound formed by 0.4 parts of tert-butyl peroxybenzoate and 0.4 parts of trimethylolpropane triacrylate) is uniformly mixed, and then the obtained mixed material is melt-blended, then squeezed and annealed. A degradable heat-resistant polylactic acid straw was obtained, and the characterization data are shown in Table 1 and Table 2.

Embodiment 2

[0041] 89.6 parts of polylactic acid, 4 parts of inorganic nucleating agent montmorillonite, 1 part of organic nucleating agent TMC200, reactive toughening agent (5 parts of epoxy soybean oil) and micro-crosslinking agent (0.4 part of ADR4468) were uniformly mixed, Afterwards, the obtained mixed materials were melt-blended, extruded and annealed to obtain a degradable heat-resistant polylactic acid straw. The characterization data are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com