Lunch box machine production line

A production line and box machine technology, applied in the field of lunch box machine manufacturing devices, can solve the problems of increased lunch box production process, inability to guarantee the quality of lunch boxes, and increased energy consumption, so as to achieve energy saving, environmental protection, normal work, and simplified production and transfer steps , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

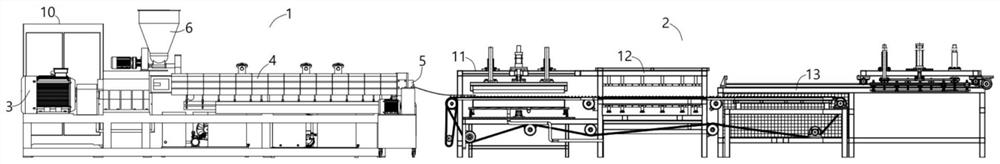

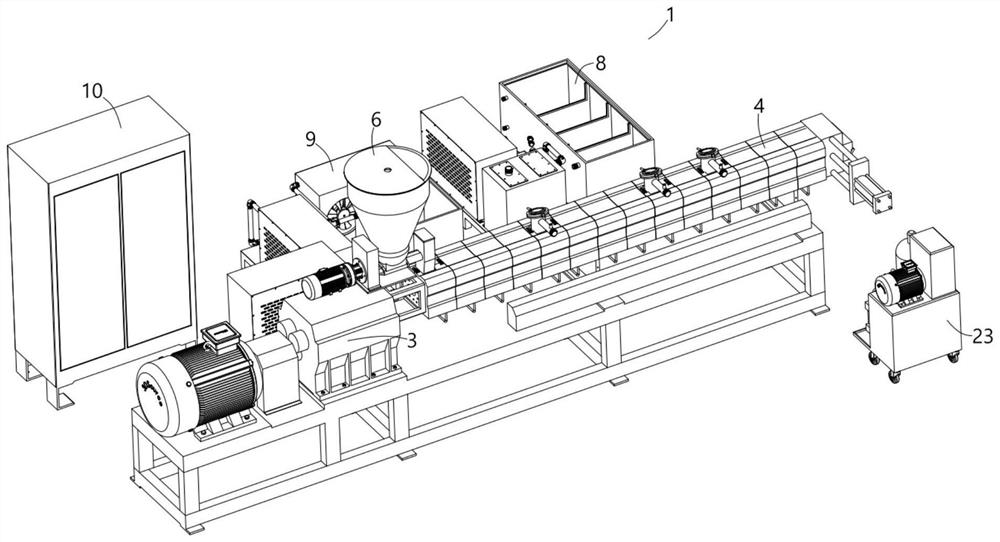

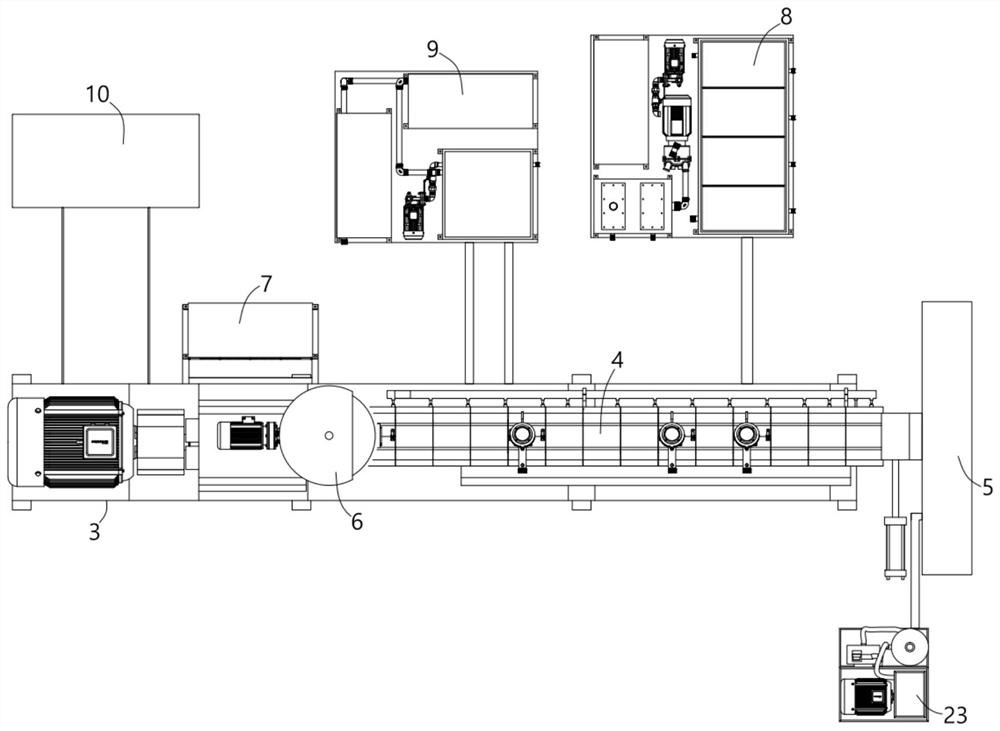

[0027] A production line for a lunch box machine, comprising a twin-screw extrusion section 1 and a lunch box forming section 2, wherein the discharge end of the twin-screw extrusion section 1 is docked with the feeding end of the lunch box forming section 2;

[0028] The twin-screw extrusion section 1 includes a power part 3, a twin-screw raw material melting part 4 and an extrusion molding part 5. The front end of the twin-screw raw material melting part 4 is provided with a feed hopper 6, and one side of the power part 3 is provided with a gearbox cold zone. 7, the twin-screw raw material melting part 4 communicates with the vacuum circulation water cooling system 9 and the gas circulation filtration system 8 respectively, and the gas circulation filtration system 8 and the vacuum circulation water cooling system 9 communicate through pipelines, the power part 3, the twin-screw raw material The melting parts 4 are electrically connected with the distribution cabinet 10;

[...

Embodiment 2

[0033] In this embodiment, the negative pressure forming part 11 is provided with a negative pressure pipe 15, and the upper part of the negative pressure pipe 15 communicates with the negative pressure chamber 16. 11 The upper end lift type is equipped with a silicone molding box 17 that pushes the extruded sheet into the cavity. When the sheet extruded material enters the negative pressure molding part 11, the silicone molding box 17 descends to push the softened sheet into the mold. In the cavity, since the cavity is connected with the negative pressure cavity 16, the negative pressure inside the negative pressure cavity 16 is negatively pressured through the negative pressure pipeline 15, so that the sheet material is adsorbed on the surface of the cavity, and the molding is formed. The forming means of the lunch box will be described in detail here.

Embodiment 3

[0035] In this embodiment, the stamping and cutting part 12 includes a stamping and cutting knife 18 arranged in a lifting manner. By lifting the stamping and cutting knife 18, the lunch box is stamped and cut from the whole sheet raw material, which is convenient for subsequent processing of the lunch box. transport.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com