Diamond grinding wheel with high wear resistance and long service life and preparation method

A diamond grinding wheel and long-life technology, which is applied in the field of abrasive and abrasive tool preparation, can solve the problems of low life and insufficient wear resistance of the grinding wheel, and achieve the effects of good wear resistance, long service life and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The electroplated diamond grinding wheel in this embodiment includes a grinding wheel substrate, an abrasive layer, and a nickel layer as a bonding agent between the two.

[0028] Diamond grinding wheel preparation method comprises the following steps in the present embodiment:

[0029] 1) Select alloy steel as the blank for preparing the grinding wheel matrix;

[0030] 2) forming the blank described in step 1) by forging;

[0031] 3) heat-treating the formed grinding wheel substrate described in step 2) at a temperature of 1000° C.;

[0032] 4) natural cooling at room temperature;

[0033] 5) Use 25°C water for tempering treatment;

[0034] 6) Carry out rough and finish machining to the emery wheel substrate after quenching and tempering in step 5) by means of a car;

[0035] 7) using an acid solution to remove impurities and decontaminate the grinding wheel substrate after the above-mentioned finishing;

[0036] 8) putting the grinding wheel substrate after remov...

Embodiment 2

[0044] The electroplated diamond grinding wheel in this embodiment includes a grinding wheel substrate, an abrasive layer, and a nickel layer as a bonding agent between the two.

[0045] Diamond grinding wheel preparation method comprises the following steps in the present embodiment:

[0046] 1) Select alloy steel as the blank for preparing the grinding wheel matrix;

[0047] 2) forming the blank described in step 1) by forging;

[0048] 3) heat-treating the formed grinding wheel substrate described in step 2) at a temperature of 1000° C.;

[0049] 4) natural cooling at room temperature;

[0050] 5) Use 25°C water for tempering treatment;

[0051] 6) Carry out rough and finish machining to the emery wheel substrate after quenching and tempering in step 5) by means of a car;

[0052] 7) using an acid solution to remove impurities and decontaminate the grinding wheel substrate after the above-mentioned finishing;

[0053] 8) putting the grinding wheel substrate after remov...

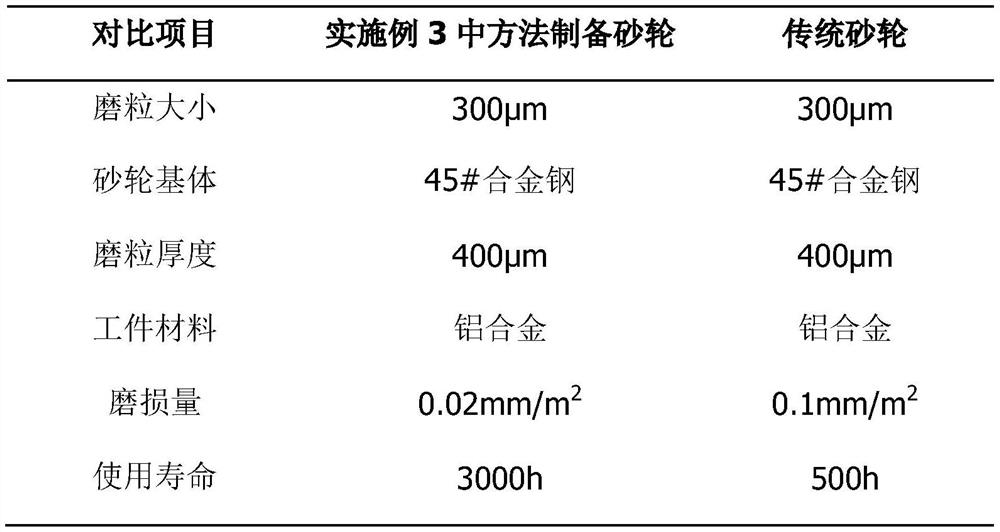

Embodiment 3

[0061] The electroplated diamond grinding wheel in this embodiment includes a grinding wheel substrate, an abrasive layer, and a nickel layer as a bonding agent between the two.

[0062] Diamond grinding wheel preparation method comprises the following steps in the present embodiment:

[0063] 1) Select alloy steel as the blank for preparing the grinding wheel matrix;

[0064] 2) forming the blank described in step 1) by forging;

[0065] 3) heat-treating the formed grinding wheel substrate described in step 2) at a temperature of 1000° C.;

[0066] 4) natural cooling at room temperature;

[0067] 5) Use 25°C water for tempering treatment;

[0068] 6) Carry out rough and finish machining to the emery wheel substrate after quenching and tempering in step 5) by means of a car;

[0069] 7) using an acid solution to remove impurities and decontaminate the grinding wheel substrate after the above-mentioned finishing;

[0070] 8) putting the grinding wheel substrate after remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com