Welding flux for welding ultra-small spacing element, preparation method and welding method

A welding method and small-pitch technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problem of short-circuit of ultra-fine-pitch components, reduce the risk of short-circuit, improve the production process capability of the industry, and ensure semiconductor The effect of product packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

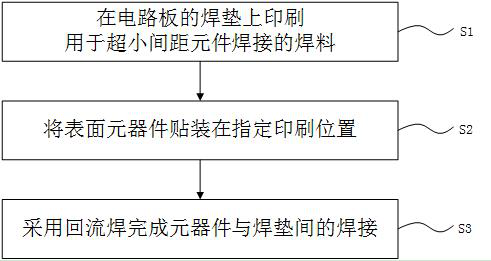

Method used

Image

Examples

Embodiment 1

[0022] An ultra fine pitch solder element for welding, comprising 5 parts by weight parts of tin powder, 95 parts of ordinary flux.

[0023] The tin powder is Sn96.6Ag3Cu0.5, mixed with one or more other Sn96.5Ag3.5 alloy.

[0024] Common parts by weight of the flux comprises 10 to 20 parts of resin, 5 to 10 parts of a wetting agent, from 2 to 10 parts thixotropic agent, 40 to 70 parts solvent, lactic --10 to 15 parts glycolic acid copolymer, monophosphate esters of 3 to 6 parts.

[0025] Welding ends of individual elements do not provide sufficient solder, solder of the present application provides the added tin powder can complement solder trace.

[0026] Resin is extracted from the secretions of trees belonging to the natural non-corrosive product, presenting activity in the liquid plays the role of flux.

[0027] Wetting agent lowers the surface tension of the flux, increasing affinity and wettability of the solder powder butt pad.

[0028] Thixotropic agents capable of impart...

Embodiment 2

[0041] According to a second embodiment of the first embodiment except that, for ultra fine pitch solder welding element, comprising in parts by weight 10 parts tin powder, 90 parts of ordinary flux. Production method: 10 parts by weight of tin powder in 90 parts by weight of a common flux, was stirred evenly. Other parts are the same as first embodiment. Highly integrated products 4 01005 practical embodiment headto head element and ultra fine pitch (70um), using the present example solder stencil printing experiment 40um thickness by welding method according to the present embodiment, the actual production of solder shorts reduced 10ppm or less.

Embodiment 3

[0043] The third embodiment of the first embodiment except that, for ultra fine pitch solder element welding, parts by weight tin powder comprising 7 parts, 93 parts of ordinary flux. Production method: 7 parts by weight of tin powder in 93 parts by weight of a common flux, was stirred evenly. Other parts are the same as first embodiment. Highly integrated products 4 01005 element and an actual head tohead ultra fine pitch (70um), using the present example solder stencil printing experiment 40um thickness by welding method according to the present embodiment, the actual production of solder shorts reduced 10ppm or less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com