A multi-purpose filtering method with one machine

A filtering method and a multi-purpose technology, applied in the field of filtration, can solve the problems of small machine capacity, complicated program, slow filtering, etc., and achieve the effect of improving filtration efficiency, realizing multi-purpose of one machine, and convenient filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

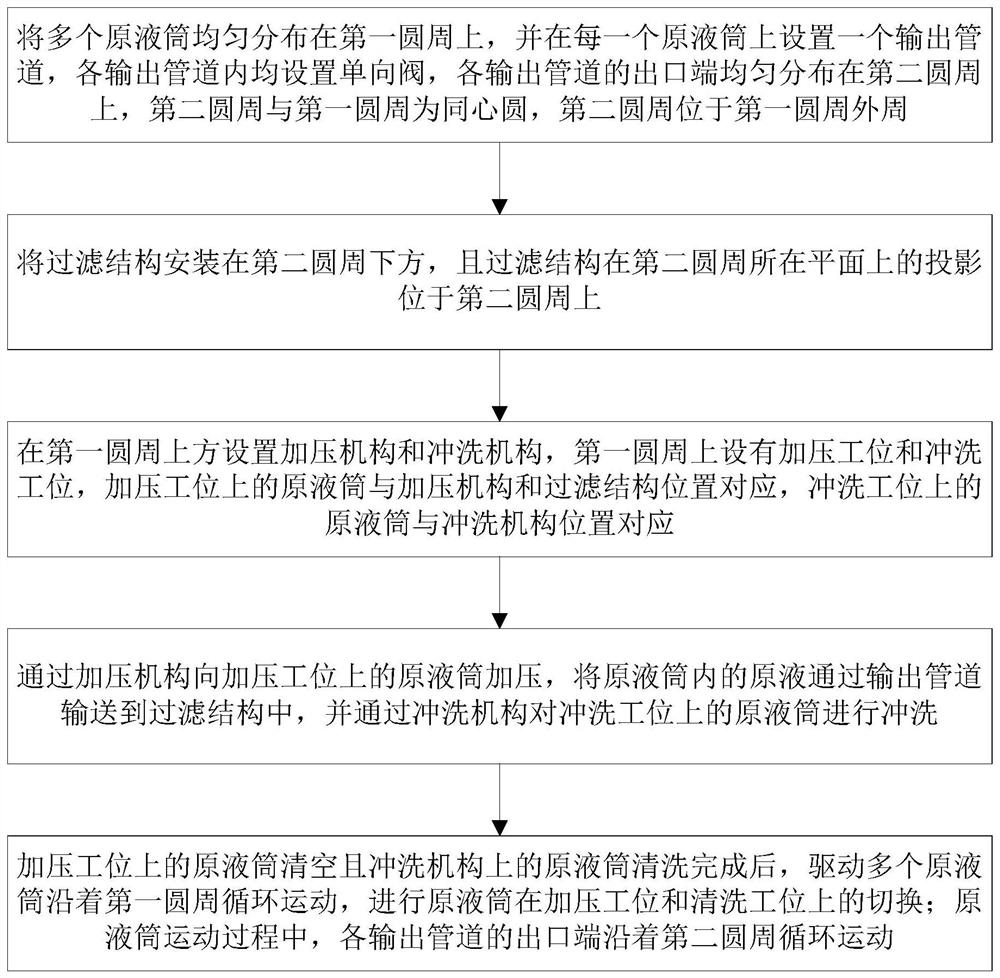

[0021] refer to figure 1 , a kind of multi-purpose filter method that the present invention proposes, comprises the following steps.

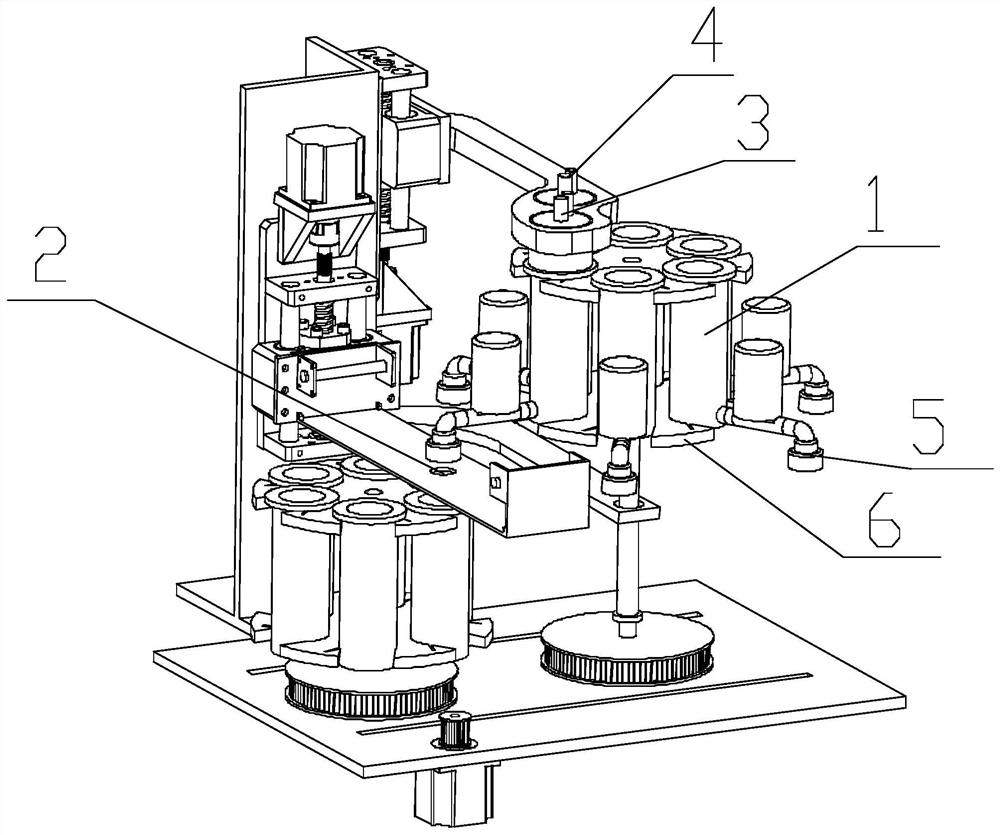

[0022] S1. Distribute a plurality of stock solution cylinders 1 evenly on the first circumference, and set an output pipe 5 on each stock solution cartridge 1, each output pipe 5 is provided with a check valve, and the outlet ends of each output pipe 5 are evenly distributed On the second circumference, the second circumference and the first circumference are concentric circles, and the second circumference is located on the outer circumference of the first circumference. Specifically, in this embodiment, a plurality of stock solution cylinders 1 are evenly distributed on the rotatable rotating bracket 6 , and the first circumference is coaxially arranged with the rotation axis of the rotating bracket 6 . In this way, it is convenient to drive each stock solution cylinder 1 to rotate through the rotation of the rotating bracket 6 . Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com