A kind of corn missed sowing and reseeding device and control method

A technology of missed seeding and corn, applied in electrical program control, program control in sequence/logic controller, planter parts, etc., can solve problems such as motor consumption and increase cost, reduce mechanical vibration, reduce power requirements, High replanting accuracy and real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

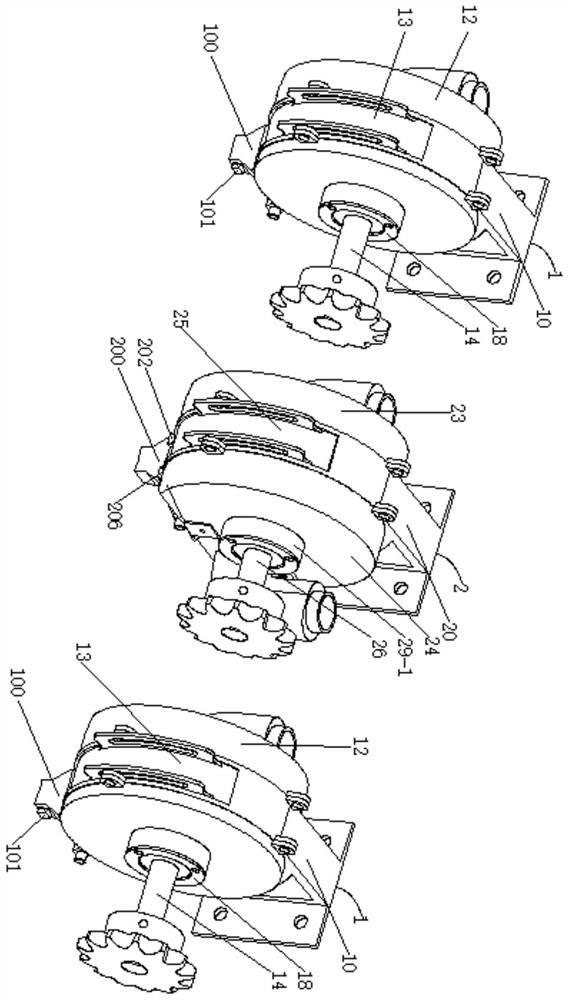

Embodiment 1

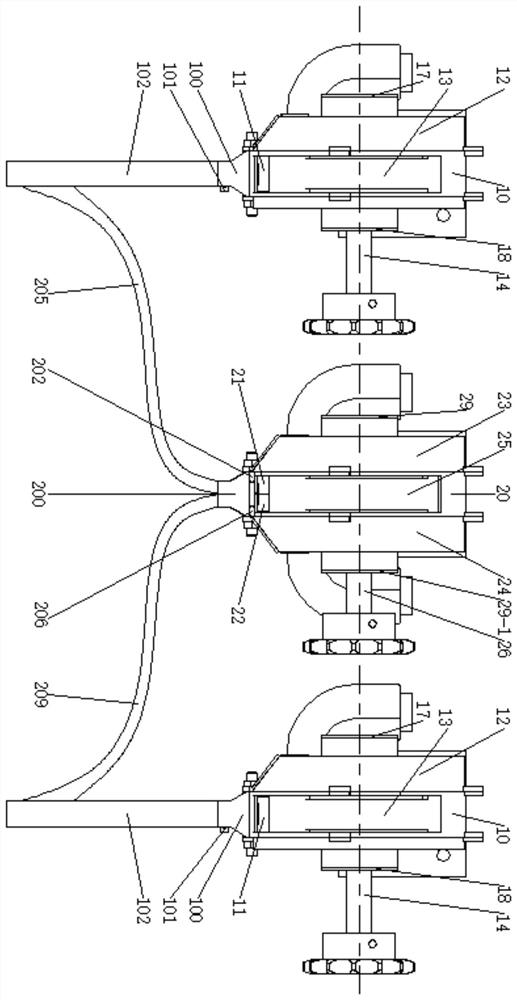

[0105] In this corn missed sowing re-seeding device, the main shaft two 26 is provided with a shoulder 26-1, and the left re-seeding disc 21 and the right re-seeding disc 22 centers are rotationally connected with the main shaft two 26, and the left re-seeding disc 21 and the right re-seeding disc 22 are rotationally connected. The right replanting disc 22 is separated by shoulder 26-1, avoiding the contact of the left reseeding disc 21 and the right reseeding disc 22 side walls, only the left reseeding disc 21 rotates replanting for the main shaft two 26 counterclockwise rotations, and the right reseeding disc 21 rotates replanting. The reseeding disk 22 does not rotate; the main shaft two 26 rotates clockwise and only the right reseeding disk 22 rotates replanting, and the left reseeding disk 21 does not rotate, providing a structural basis.

[0106] The left side of the left reseeding disc 21 is provided with a left ratchet drive assembly, and the left ratchet drive assembly...

Embodiment 2

[0113] On the basis of Embodiment 1, the number of holes 2 2-2 on the left swivel seat 21-2 is an odd number, and only one side of the left swivel seat 21-2 is provided with a left groove 21-20; The type hole 2 2-2 on the swivel base 22-2 is an odd number, and the right swivel base 22-2 is only provided with a right groove 22-20 on one side; then the left swivel base 21-2 and the right swivel base 22- 2 The lower end is provided with a balance block 21-21, which ensures the stability of the dynamic balance of the left swivel base 21-2 and the right swivel base 22-2 along with the rotation of the main shaft two 26, and reduces mechanical vibration.

[0114] The number of holes 2-2 on the left swivel base 21-2 is an even number, and left grooves 21-20 are arranged on both sides of the left swivel base 21-2; the type holes on the right swivel base 22-2 Two 2-2 are an even number, right grooves 22-20 are provided on both sides of the right swivel base 22-2, and there is no need to...

Embodiment 3

[0116] The control method of the corn leakage reseeding device, the control system includes a single-chip microcomputer, a solenoid valve 1 and a solenoid valve 2, an optical fiber sensor 101 at the lower end of the seed metering device 1 on the left side and an optical fiber sensor at the lower end of the seed metering device 1 on the right side 101 is respectively connected with the input end signal of the single-chip microcomputer, and the first electromagnetic valve and the second electromagnetic valve are connected with the output end signal of the single-chip microcomputer. 206 is connected by a trachea.

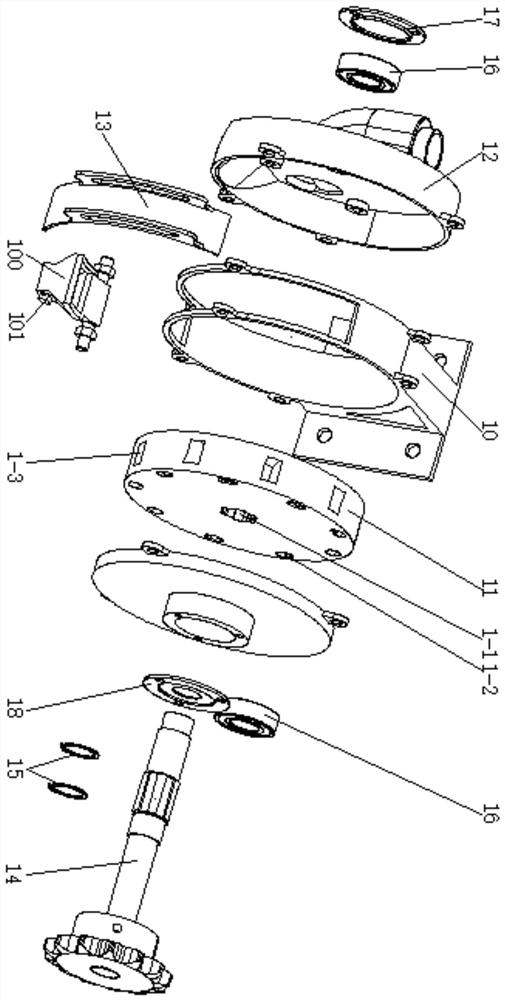

[0117] First put the corn seeds into the first seed-filling chamber cover 12 on both sides and the left seed-filling chamber cover 23 and right seed-filling chamber cover 24 in the middle, then the seed meters 1 on both sides work, and the main shaft one 14 passes through the outer The cooperation between the spline and the spline hole 1-1 drives the seeding disk 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com