An optocoupler with the simplest package and its assembly method

An assembly method and optocoupler technology, which are used in measuring devices, engine lubrication, and lubrication indicating devices, etc., can solve problems such as affecting batch production of oilfield liquid level testers, large differences in output resistance, and increasing debugging time. Solve the difficulty of installation and debugging, reduce installation requirements, and improve the effect of output resistance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

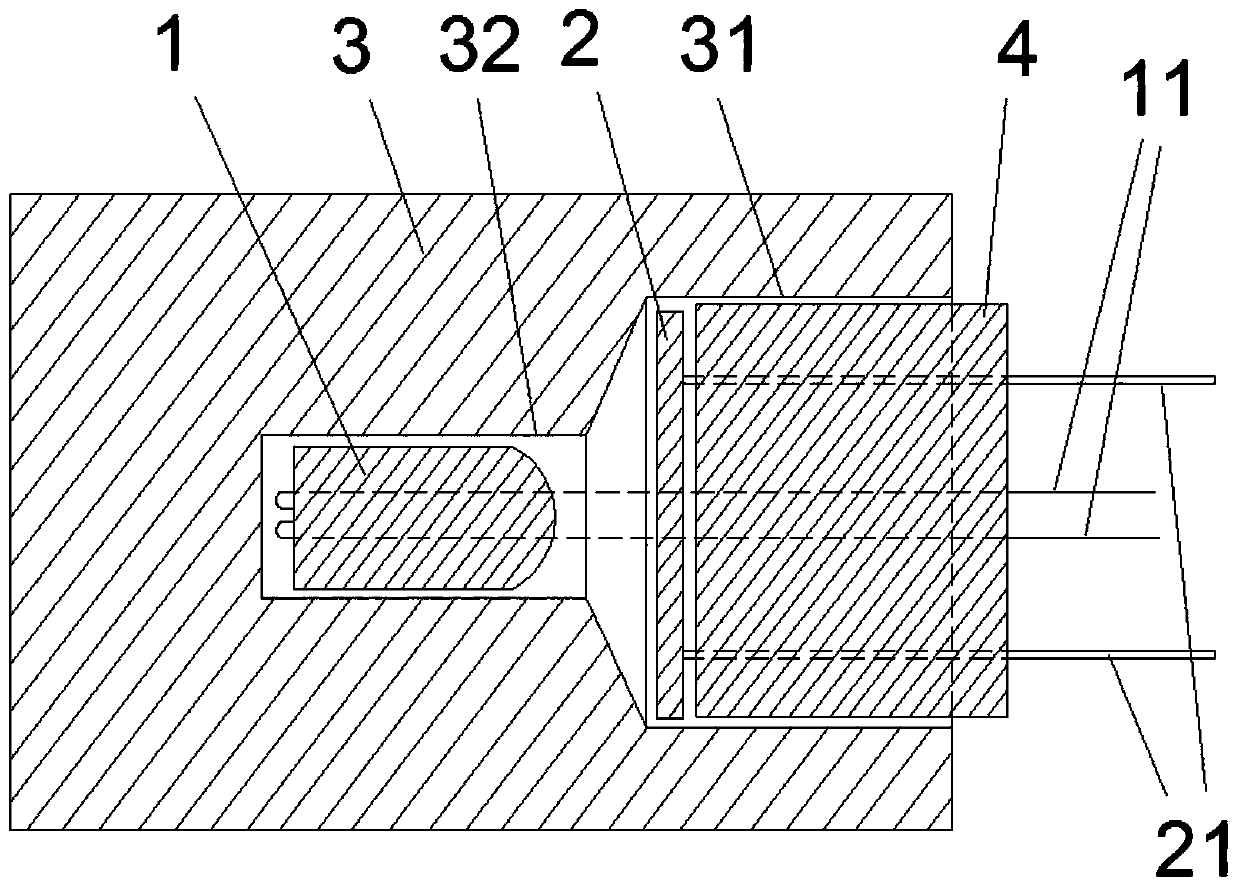

[0013] refer to figure 1 , this embodiment provides an optocoupler with the simplest package, including a black bushing 3, one end of the black bushing 3 is provided with a first blind hole 31 for placing a resistor, and the bottom of the first blind hole 31 is provided with a second blind hole 32. The aperture diameter of the second blind hole 32 is smaller than the aperture diameter of the first blind hole 31, and both are coaxial. The tungsten filament lamp bead 1 is placed in the second blind hole 32 with its pin facing inward, and the tungsten filament lamp bead 1 is placed along the second blind hole 32. The length direction of the blind hole 32 is set, and the pins of the in-line photoresistor 2 are placed in the first blind hole 31 facing outward, and the plate body of the in-line photoresistor 2 is perpendicular to the tungsten lamp bead 1, and the outside of the in-line photoresistor 2 The first blind hole 31 is sealed by the black sealant 4 , and the pins of the tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com