Sulfur vacancy-containing NiS quantum dot/S, N, O co-doped carbon electrode material and preparation method thereof

A technology of electrode materials and quantum dots, applied in the direction of electrodes, chemical instruments and methods, electrolytic components, etc., can solve the problems of difficult interface coupling, complicated and cumbersome electrode process, and low electrocatalytic efficiency, so as to facilitate charge transfer and improve High hydrogen evolution performance and high electrocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) 0.005mol NiCl 2 ·6H 2 O. Mix 0.0075mol methylthiouracil and 0.01mol ethylene glycol, heat and stir in an oil bath at 70°C for 0.4h to form a homogeneous liquid;

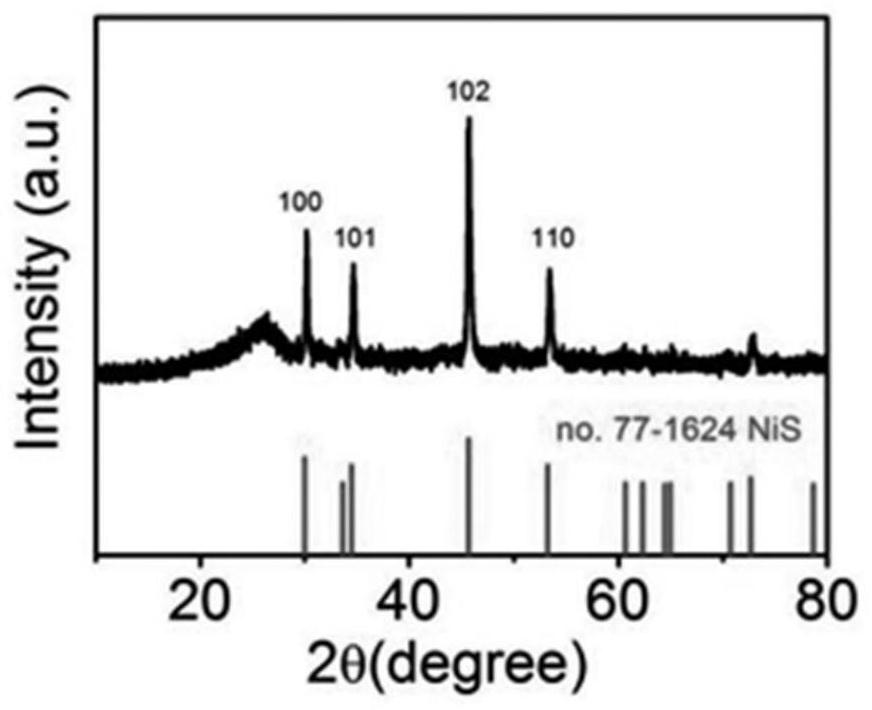

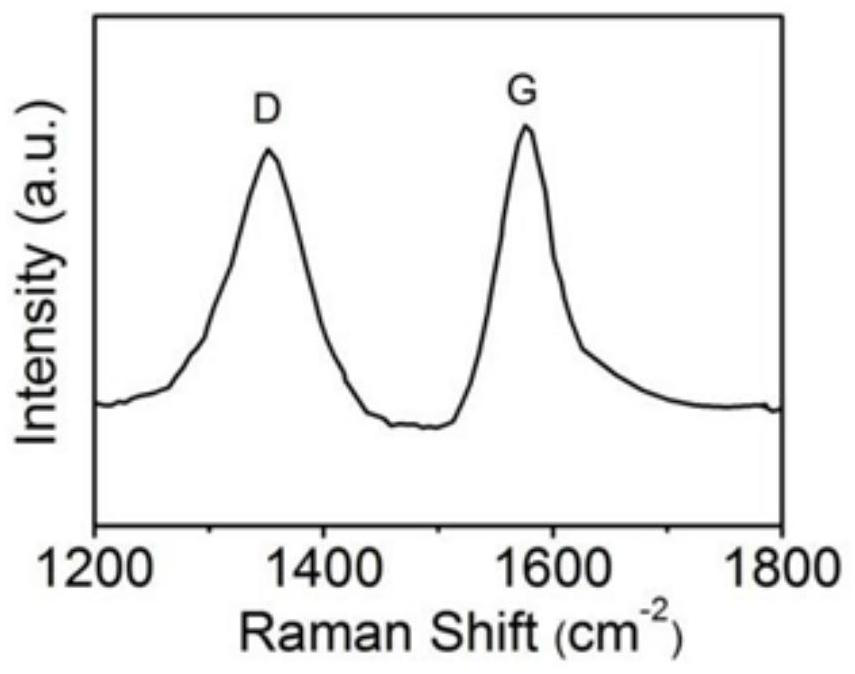

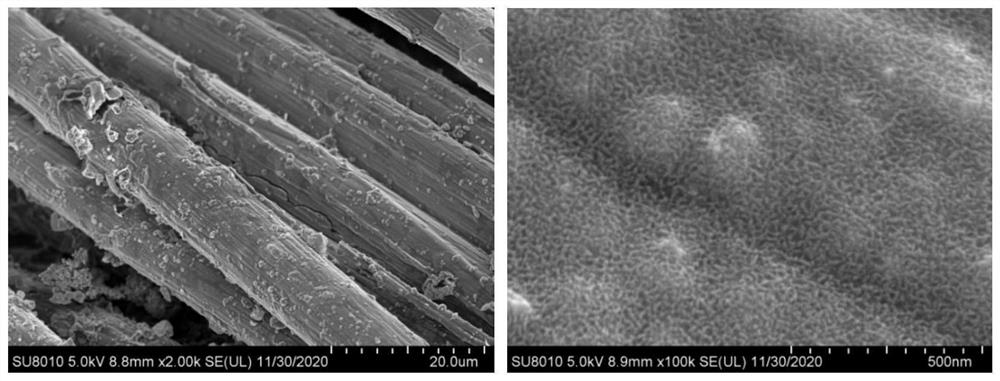

[0023] (2) Apply the homogeneous liquid obtained in step (1) evenly on the surface of the carbon cloth, put the obtained carbon cloth into a porcelain boat, wrap the porcelain boat with aluminum foil, put the wrapped porcelain boat into a tube furnace, Replace the air with high-purity nitrogen, heat to 550°C at a rate of 5°C / min under airtight conditions, and keep it for 4h to obtain sulfur-vacancy NiS quantum dots / S, N, O co-doped carbon grown on carbon cloth Network structure composites.

Embodiment 2

[0025] (1) 0.005mol NiCl 2 ·6H 2 O. Mix 0.0075mmol methylthiouracil and 0.02mmol ethylene glycol, heat and stir in an oil bath at 70°C for 0.4h to form a homogeneous liquid;

[0026] (2) Apply the homogeneous liquid obtained in step (1) evenly on the surface of the carbon cloth, put the obtained carbon cloth into a porcelain boat, wrap the porcelain boat with aluminum foil, put the wrapped porcelain boat into a tube furnace, Replace the air with high-purity nitrogen, heat to 550°C at a rate of 5°C / min under airtight conditions, and keep it for 4h to obtain sulfur-vacancy NiS quantum dots / S, N, O co-doped carbon grown on carbon cloth Network structure composites.

Embodiment 3

[0028] (1) 0.005mmol NiCl 2 ·6H 2 O. Mix 0.0075mmol methylthiouracil and 0.005mol ethylene glycol, heat and stir in an oil bath at 70°C for 0.4h to form a homogeneous liquid;

[0029] (2) Apply the homogeneous liquid obtained in step (1) evenly on the surface of the carbon cloth, put the obtained carbon cloth into a porcelain boat, wrap the porcelain boat with aluminum foil, put the wrapped porcelain boat into the tube furnace, Replace the air with high-purity nitrogen, heat to 550°C at a rate of 5°C / min under airtight conditions, and keep it for 4h to obtain sulfur-vacancy NiS quantum dots / S, N, O co-doped carbon grown on carbon cloth Network structure composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com