High-entropy Prussian blue material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing a high-entropy Prussian blue-like sodium-ion battery cathode material, comprising the following steps:

[0049] Dissolve 3 mol of sodium ferrocyanide decahydrate, 10 g of polyvinylpyrrolidone, and 2 mol of sodium citrate in a mixed solvent consisting of 1 L of deionized water and 100 mL of absolute ethanol to obtain a precursor solution A;

[0050]Dissolve 0.3 mol manganese sulfate, 0.3 mol copper sulfate, 0.3 mol nickel acetate, 0.3 mol cobalt chloride, 0.3 mol ferric nitrate and 2 mol sodium citrate in a mixed solvent composed of 1L deionized water and 100mL absolute ethanol to obtain a precursor solution B;

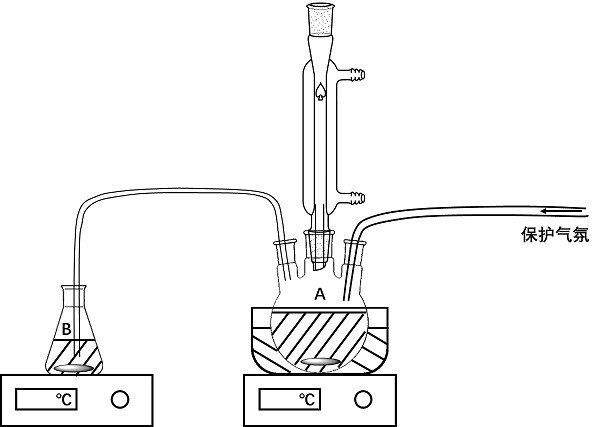

[0051] use figure 1 The device shown is for co-precipitation reaction, wherein container A contains precursor solution A, container B contains precursor solution B, and the precursor solution B is slowly dripped into container A at a rate of 1 mL / min through a silicone tube using a peristaltic pump , and the temp...

Embodiment 2

[0060] This embodiment provides a method for preparing a high-entropy Prussian blue-like sodium-ion battery cathode material, comprising the following steps:

[0061] 4mol sodium ferrocyanide decahydrate, 20g cetyltrimethylammonium bromide, and 1mol1-10-phenanthroline were dissolved in a mixed solvent composed of 1L deionized water and 300mL anhydrous n-butanol, Obtain precursor solution A;

[0062] Dissolve 0.4mol manganese chloride, 0.4mol copper oxalate, 0.4mol nickel acetate, 0.4mol ethylenediaminetetraacetic acid cobalt, 0.4mol ferric nitrate, 0.4mol titanium chloride and 1mol 1-10-phenanthroline in 1L deionized Precursor solution B is obtained in a mixed solvent composed of water;

[0063] use figure 1 The device shown is for co-precipitation reaction, wherein container A contains precursor solution A, container B contains precursor solution B, and the precursor solution B is slowly added dropwise to container A at a rate of 5 mL / min through a silicone tube using a per...

Embodiment 3

[0071] This embodiment provides a method for preparing a high-entropy Prussian blue-like sodium-ion battery cathode material, comprising the following steps:

[0072] Dissolve 1mol of sodium ferrocyanide decahydrate, 300g of sodium dodecylbenzenesulfonate, and 0.1mol of disodium edetate in a mixed solvent consisting of 1L of deionized water and 100mL of anhydrous methanol to obtain a precursor solution A;

[0073] Dissolve 0.2mol manganese sulfate, 0.1mol copper sulfate, 0.1mol nickel acetate, 0.2mol titanium chloride, 0.2mol vanadium chloride, 0.2mol chromium chloride and 0.001mol edetate disodium in 1L deionized water and Precursor solution B was obtained in a mixed solvent composed of 500mL absolute ethanol;

[0074] use figure 1 The device shown is for co-precipitation reaction, wherein container A contains precursor solution A, container B contains precursor solution B, and uses a peristaltic pump to slowly drop precursor solution B to container A at a rate of 50 mL / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com