Vulcanization resistance evaluation method

An evaluation method and anti-sulfurization technology, which is applied in measurement devices, instruments, scientific instruments, etc., to achieve the effects of accurate and rapid evaluation, easy operation and low toxicity of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

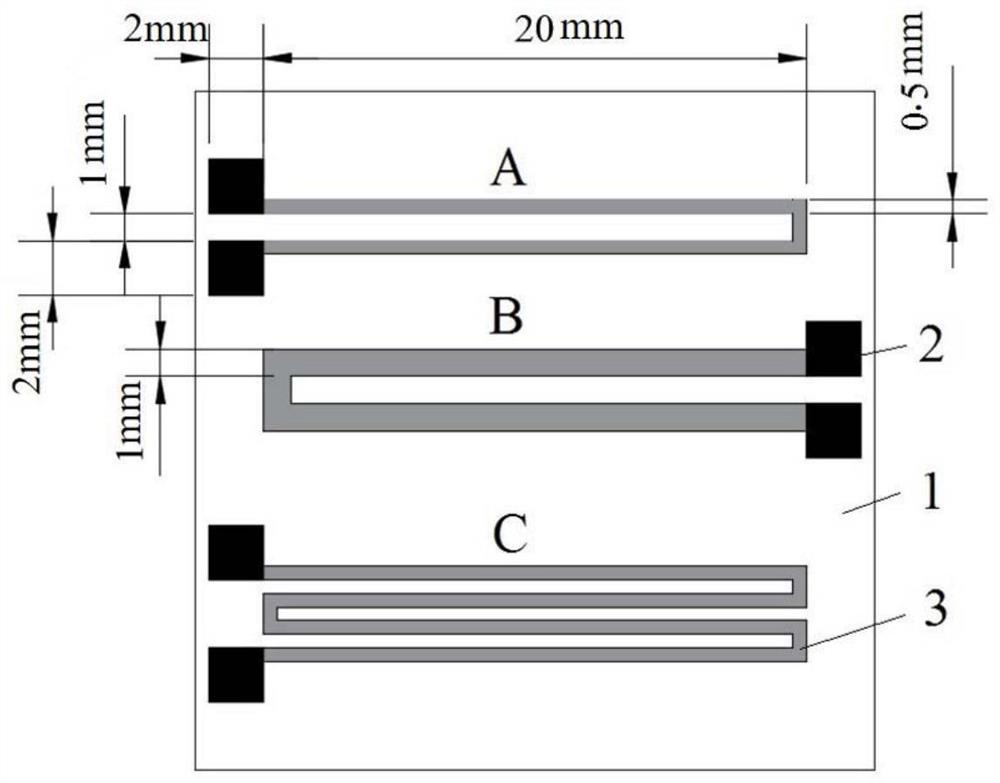

[0022] With a side length of 25mm, a thickness of 0.3mm, and a single-sided polished 99% alumina substrate, press figure 1 As shown in the three patterns of A, B, and C, the silver paste containing 65% silver is printed on the polished surface of the alumina substrate 1 with a 300-mesh screen, and fired at 850 ° C for 15 minutes in the air to obtain different patterns. Three silver electrode samples, each silver electrode sample includes two silver electrodes 2 and a silver electrode test terminal 3 .

[0023] Using thiourea with 99% purity as raw material, weigh 4g, 6g, 8g, and 10g of thiourea with a precision electronic balance and place them in a 200mL glass beaker, add 100mL of deionized water and stir until the thiourea is completely dissolved to make a concentration of 40g / L , 60g / L, 80g / L, 100g / L four thiourea solutions.

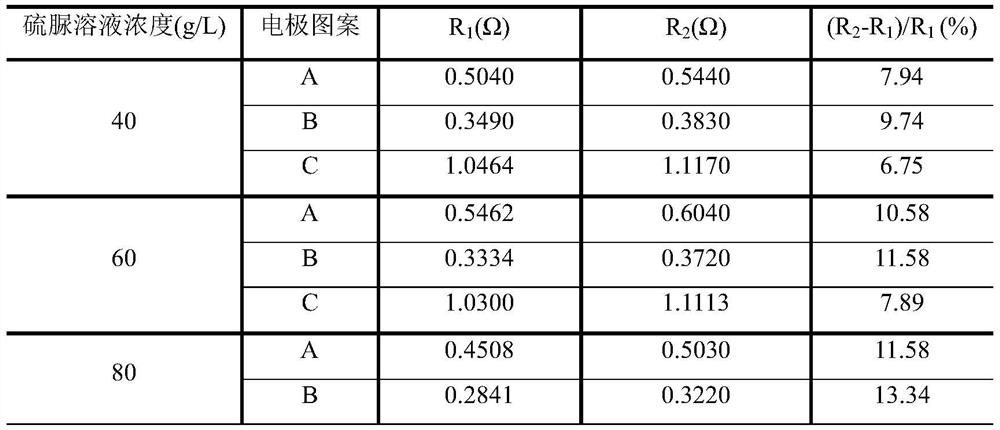

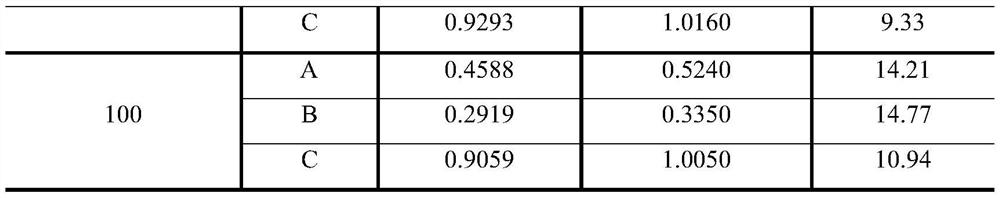

[0024] After the above four thiourea solutions were heated to 85° C. by a water bath and kept warm for 15 minutes, the three silver electrode sample...

Embodiment 2

[0037] Take RHS-03K1000FT and RHS-03K1001FT anti-sulfurization thick film chip resistors as test samples, the sample size specification is 0603, the resistance values are 100Ω and 1kΩ respectively, the resistance accuracy is ±1%, and the power is 1 / 10W.

[0038] With reference to Example 1, four kinds of thiourea solutions with concentrations of 40g / L, 60g / L, 80g / L and 100g / L were prepared. After heating to 85°C in a water bath and keeping it warm for 15 minutes, the above-mentioned anti-sulfurization thick film chip resistor samples were respectively immersed in the thiourea solution in a glass beaker, and the timing was started. After 2 h, the samples immersed in the thiourea solution were taken out, rinsed with deionized water and dried.

[0039] Use a Keithley 2010 digital multimeter to measure the resistance value R of an anti-sulfurization thick film chip resistor sample immersed in a thiourea solution 2 , and with the resistance value R before immersion in thiourea s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com