Combustor and steam generation system using same

A generation system and burner technology, which is applied in steam generation, burners, gas fuel burners, etc., can solve the problems of increasing carbon emissions and waste heat emissions, waste of gas energy, and high working noise, and achieves the reduction of working noise, The effect of improving combustion efficiency and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

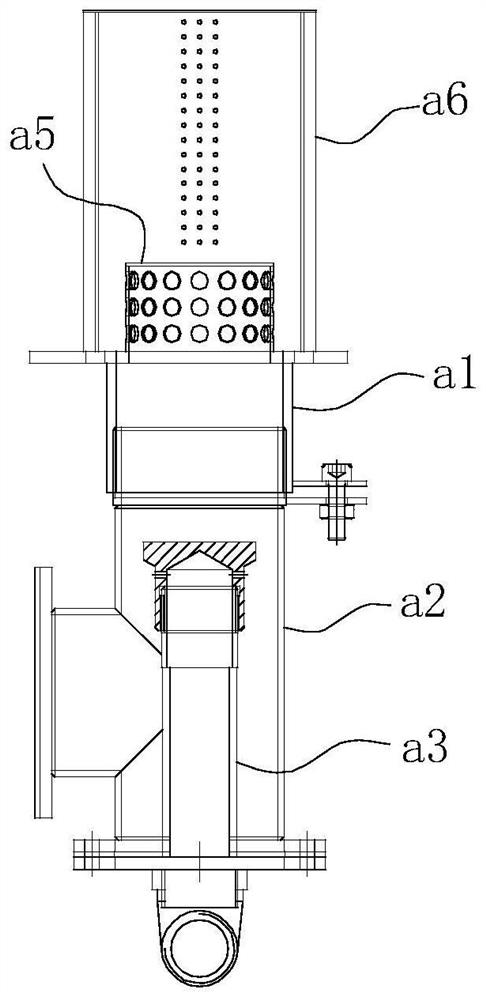

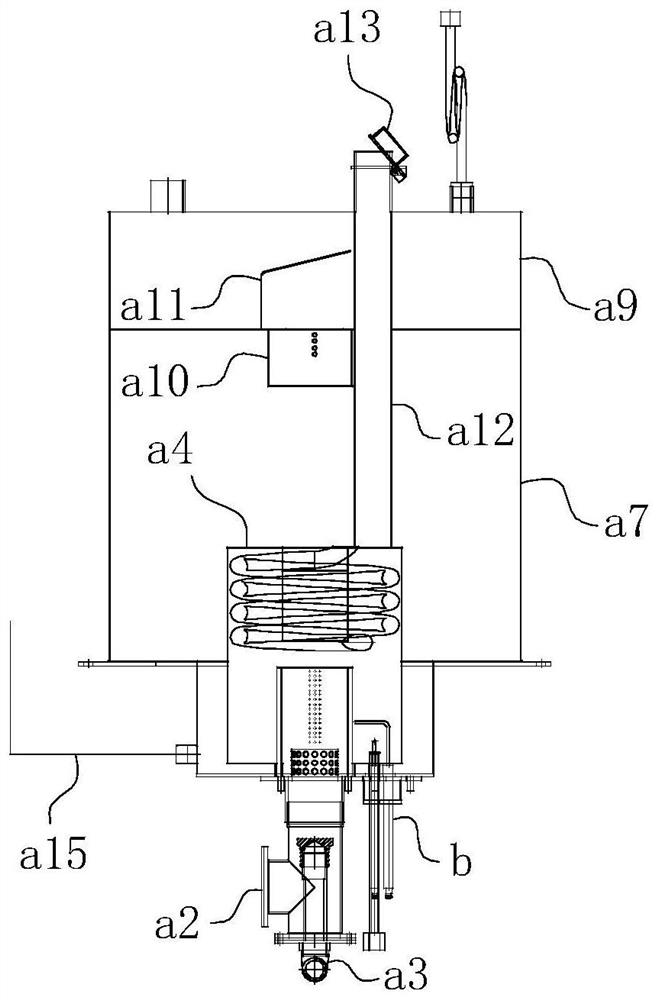

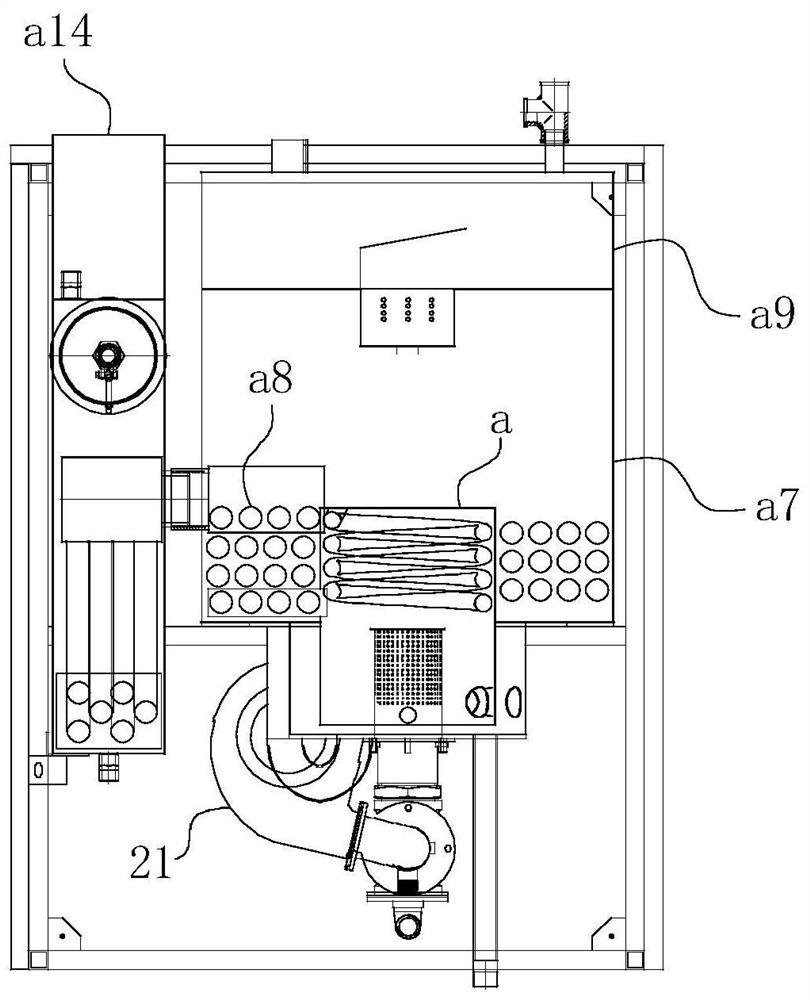

[0058] For ease of understanding, combined here Figure 1-16 , the concrete structure and working mode of the present invention are further described as follows:

[0059] The specific structure of the present invention is as Figure 1-16 As shown, its main structure includes a steam generator with a burner a and an air assembly for supplying air and air to the steam generator, wherein:

[0060] The structural form of the steam generator of the present invention is a cylinder structure, and the fuel is liquefied petroleum gas, natural gas, biogas or blast furnace gas. In the actual design, the gas pressure stabilizing valve 19c needs to be arranged to ensure that the gas input pressure of the equipment does not exceed the gas pressure upper limit; the corresponding gas pressure switch is installed at the outlet of the gas stabilizing valve to ensure that the gas pressure is within a certain Within the pressure range, beyond this range, the gas pressure switch will close the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com