Lithium secondary battery

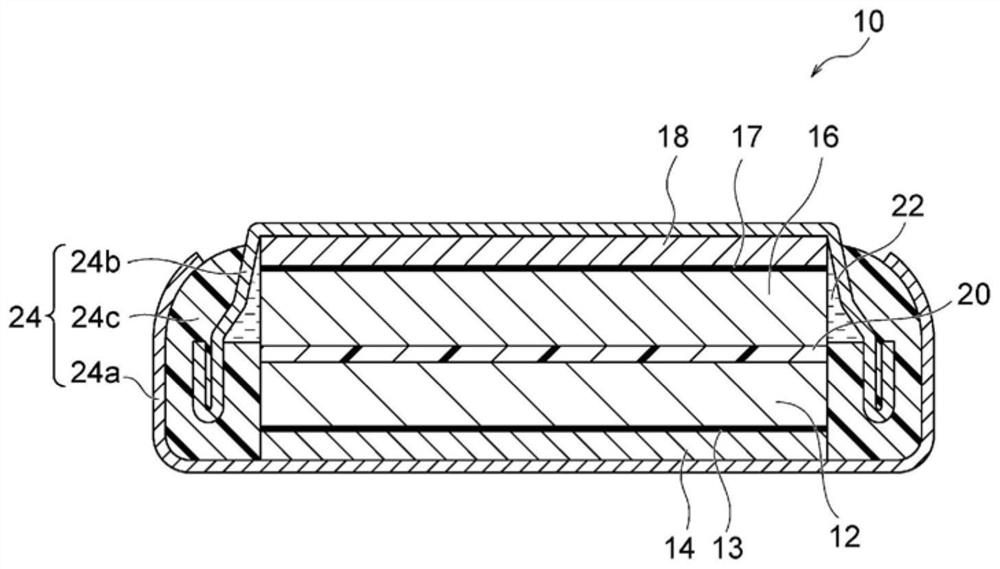

A lithium secondary battery and electrolyte technology, applied in secondary batteries, lithium batteries, battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] The present invention will be further specifically described using the following examples. It should be noted that in the following example, LiCoO 2 Abbreviated as "LCO", the Li 4 Ti 5 o 12 Abbreviated as "LTO".

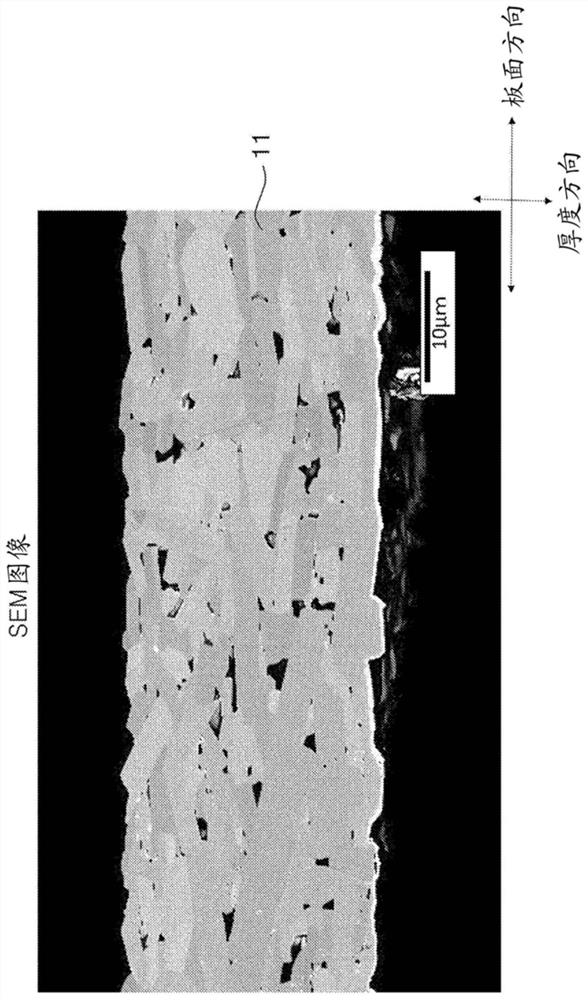

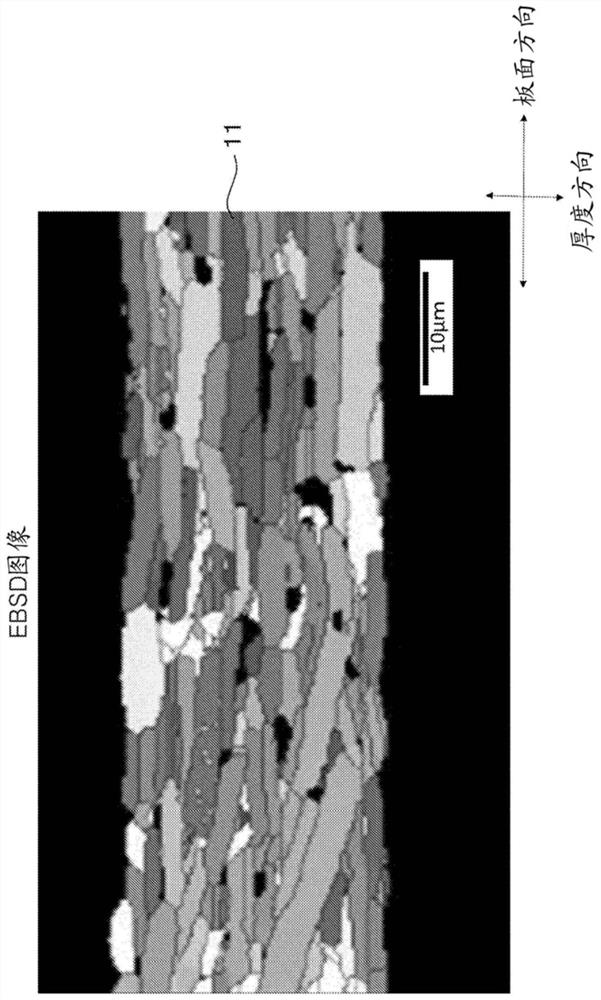

[0084] Example A1

[0085] (1) Production of LCO green sheet (positive electrode green sheet)

[0086] First, the Co weighed in such a way that the Li / Co molar ratio is 1.01 3 o 4 Powder (manufactured by Zhengdo Chemical Industry Co., Ltd.) and Li 2 CO 3 Powders (manufactured by Honjo Chemical Co., Ltd.) were mixed and held at 780° C. for 5 hours, and the resulting powder was pulverized by a pot mill so that the volume basis D50 was 0.4 μm to obtain a powder containing LCO plate-like particles. 100 parts by weight of the obtained LCO powder, 100 parts by weight of a dispersion medium (toluene:isopropanol=1:1), a binder (polyvinyl butyral: model BM-2, manufactured by Sekisui Chemical Co., Ltd.) 10 parts by weight, 4 parts by weight of plasticizer (D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com