Lithium ion battery safety coating slurry and dispersion method thereof

A lithium-ion battery and coating slurry technology, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of inability to store for a long time, the overall performance of the battery is reduced, and it is difficult to dry out moisture. , to improve the overall performance of the battery, increase the suspension performance, and reduce the swelling phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The lithium-ion battery safety coating slurry in this embodiment consists of the following components in parts by mass:

[0033] Boehmite 90, polyvinylidene fluoride 10, alkoxy ammonium salt of acid group block copolymer 0.1, N-methyl-2-pyrrolidone 140, the dispersion method of the uniform and stable suspension is as follows;

[0034] (1) Preparation of pre-mixed glue: Sprinkle polyvinylidene fluoride evenly into weighed N-methyl-2-pyrrolidone, stir in a sealed container at 15 rpm and 1200 rpm for 6 hours, polyvinylidene fluoride Completely dissolved in N-methyl-2-pyrrolidone to obtain a premixed glue with a mass concentration of 10%;

[0035] (2) Preparation of anhydrous boehmite material: add boehmite into the grinding tank, and the grinding time is 0.5h; the particle size D50 of the boehmite after grinding is 100-3000nm, and keep the ground boehmite at -0.9~- 0.85MPa vacuum degree, keep high temperature 150℃±5℃ and bake for 4h;

[0036](3) Preparation of low-molecu...

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that the lithium-ion battery safety coating slurry of this example is composed of the following components in parts by mass: boehmite 90, polyvinylidene fluoride 10, acid group block Alkoxyl ammonium salt of the copolymer 0.1, N-methyl-2-pyrrolidone 550; 15% N-methyl-2-pyrrolidone was added in step (5); the rest of the steps were the same as in Example 1.

Embodiment 3

[0050] The difference between embodiment 3 and comparative example 1 is to remedy the slurry with flocculation problem, and re-add 1% of acidic group block copolymer to the slurry in comparative example 1 that has been separated for 10d under the sealed state. Alkoxyl ammonium salts. First, stir and disperse for 4 hours according to the revolution of 25rpm and the rotation of 3500rpm; then transfer the mixed solution into the cone mill, with a flow rate of 10L / h and a linear velocity of 23m / s, and circulate 10 times;

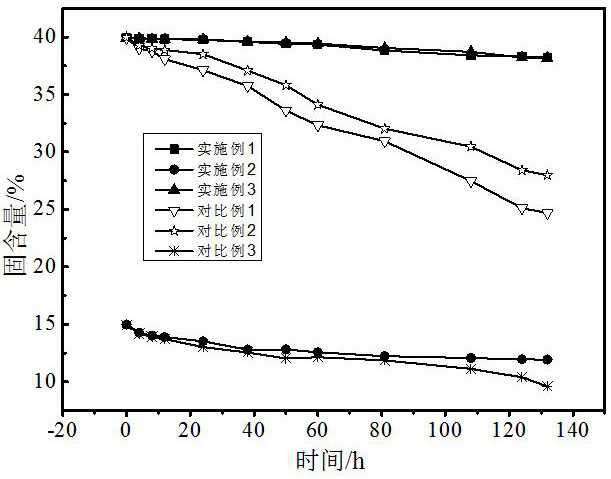

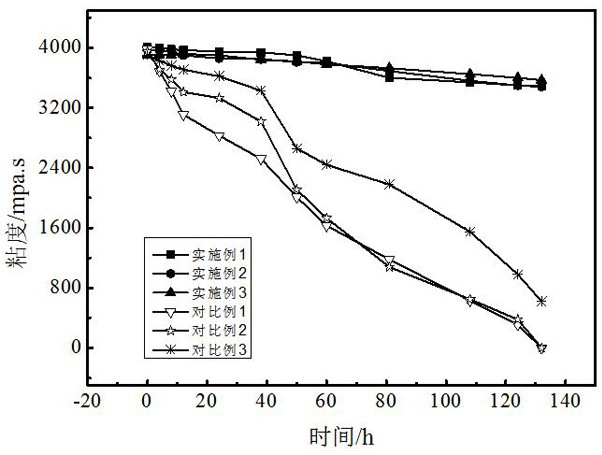

[0051] By the solid content of embodiment 1~3 and comparative example 1~3 and viscosity variation data figure 1 and figure 2 It can be seen from the comparison that the solid content of the ceramic slurry prepared in Comparative Example 1 without adding a wetting and dispersing agent, Comparative Example 2 with magnetic stirring, and Comparative Example 3 with ultrasonic and magnetic stirring cycles decreased rapidly, and the viscosity of the slurry decreased ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com