Methyl methacrylate and butyl methacrylate bicontinuous emulsion copolymerized porous material and preparation method thereof

A technology of butyl methacrylate and methyl methacrylate, which is applied in the field of material preparation, can solve problems such as difficult control of polymerization temperature and molecular weight, and achieve the effects of easy dissipation of heat energy, lower initiation temperature, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

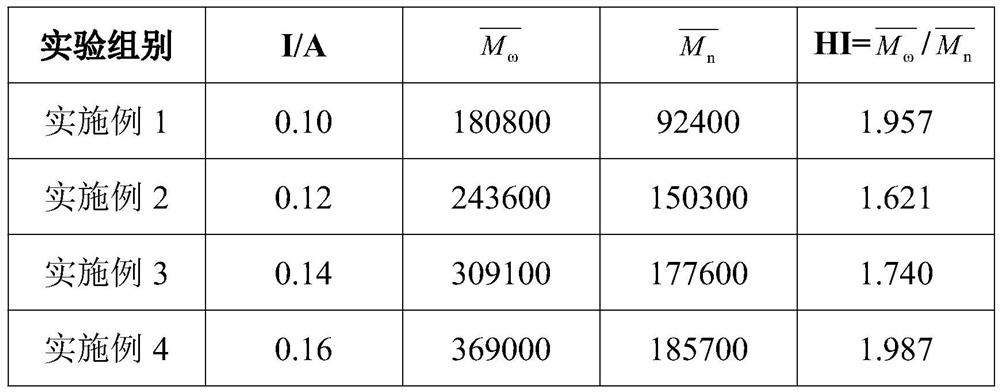

Embodiment 1

[0034] A method for preparing a methyl methacrylate and butyl methacrylate double continuous emulsion copolymer porous material, comprising the following steps:

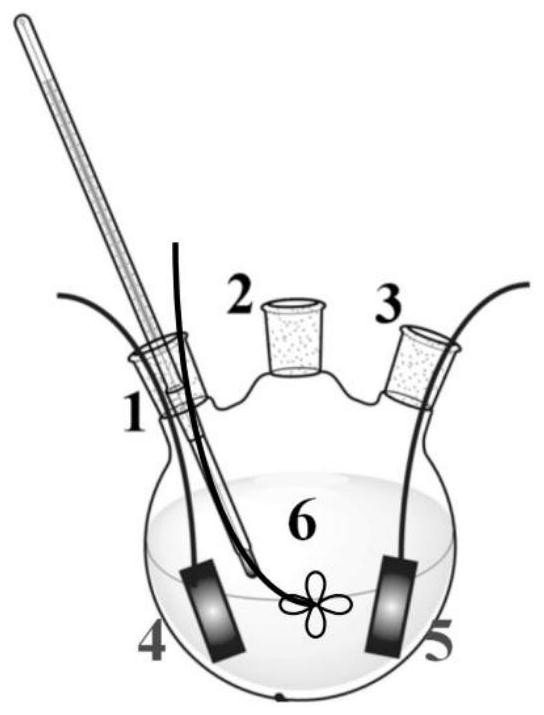

[0035] S1: Assemble the reaction apparatus (see figure 1 ), feed nitrogen to deoxygenate the reaction unit;

[0036] The reaction device includes an iron sheet, a three-necked flask, gas path branches, an external control device, a temperature control device, and a reference electrode;

[0037] The surface of the iron sheet has been cleaned by 1mol / L hydrochloric acid to remove the oxide layer. It is smooth and free of impurities, and is smaller than the diameter of the flask mouth. Two different flask mouths are respectively drawn out through red copper wires as the working electrode and the counter electrode;

[0038] The copper wire is always above the reaction liquid level, and a small part is exposed outside the PTFE rod, and the PTFE is polytetrafluoroethylene;

[0039] The PTFE rod is hollow and contains cop...

Embodiment 2

[0054] A method for preparing a methyl methacrylate and butyl methacrylate double continuous emulsion copolymer porous material, comprising the following steps:

[0055] S1: Assemble the reaction apparatus (see figure 1 ), feed nitrogen to deoxygenate the reaction unit;

[0056] The reaction device includes an iron sheet, a three-necked flask, gas path branches, an external control device, a temperature control device, and a reference electrode;

[0057] The surface of the iron sheet has been cleaned by 1mol / L hydrochloric acid to remove the oxide layer. It is smooth and free of impurities, and is smaller than the diameter of the flask mouth. Two different flask mouths are respectively drawn out through red copper wires as the working electrode and the counter electrode;

[0058] The copper wire is always above the reaction liquid level, and a small part is exposed outside the PTFE rod, and the PTFE is polytetrafluoroethylene;

[0059] The PTFE stick is hollow and contains c...

Embodiment 3

[0074] A method for preparing a methyl methacrylate and butyl methacrylate double continuous emulsion copolymer porous material, comprising the following steps:

[0075] S1: Assemble the reaction apparatus (see figure 1 ), feed nitrogen to deoxygenate the reaction unit;

[0076] The reaction device includes an iron sheet, a three-necked flask, gas path branches, an external control device, a temperature control device, and a reference electrode;

[0077] The surface of the iron sheet has been cleaned by 1mol / L hydrochloric acid to remove the oxide layer. It is smooth and free of impurities, and is smaller than the diameter of the flask mouth. Two different flask mouths are respectively drawn out through red copper wires as the working electrode and the counter electrode;

[0078] The copper wire is always above the reaction liquid level, and a small part is exposed outside the PTFE rod, and the PTFE is polytetrafluoroethylene;

[0079] The PTFE stick is hollow and contains c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com