Rod-shaped preform with high length-diameter ratio and preparation method of rod-shaped preform

A high aspect ratio, prefabricated technology, used in textiles and papermaking, knitting, sewing equipment, etc., can solve problems such as uneven distribution of fiber reinforcements in thread teeth, and the effect of shear direction on the performance of bolt fasteners. To achieve the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

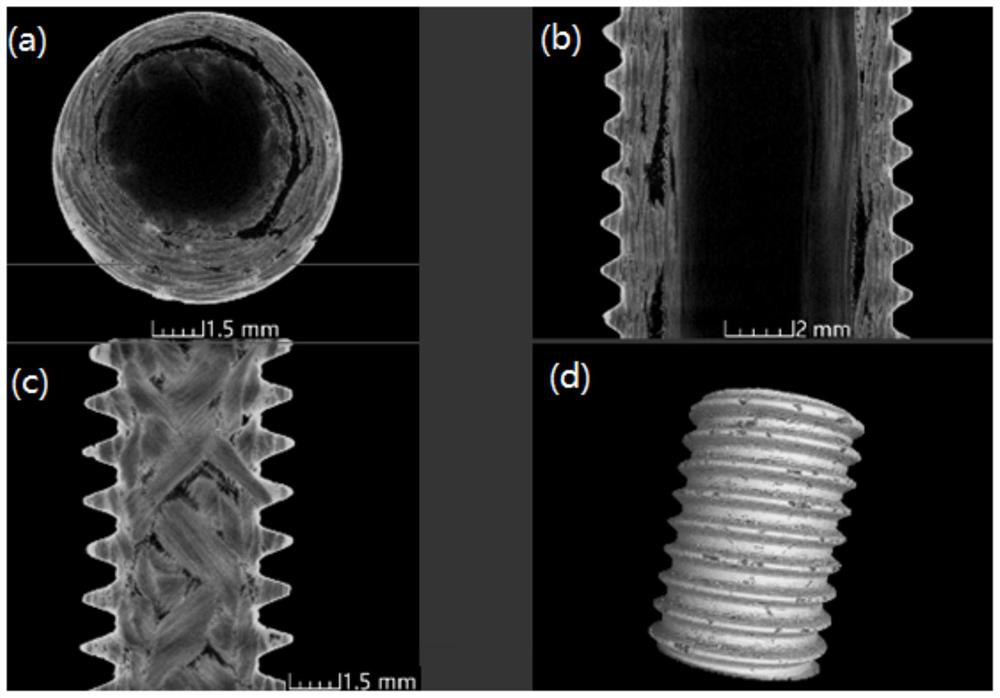

[0058] from figure 1 It can be seen that the high aspect ratio rod-shaped preform in this embodiment is composed of a core structure 1 and a cladding structure 2, wherein the core structure 1 is a cylinder formed by a plurality of fiber bundles arranged in the same direction; the cladding structure 2 It is a tubular fiber bundle braided layer woven by tube braiding method, which is sewn on the outer peripheral surface of the core structure. The aspect ratio is about 100-200.

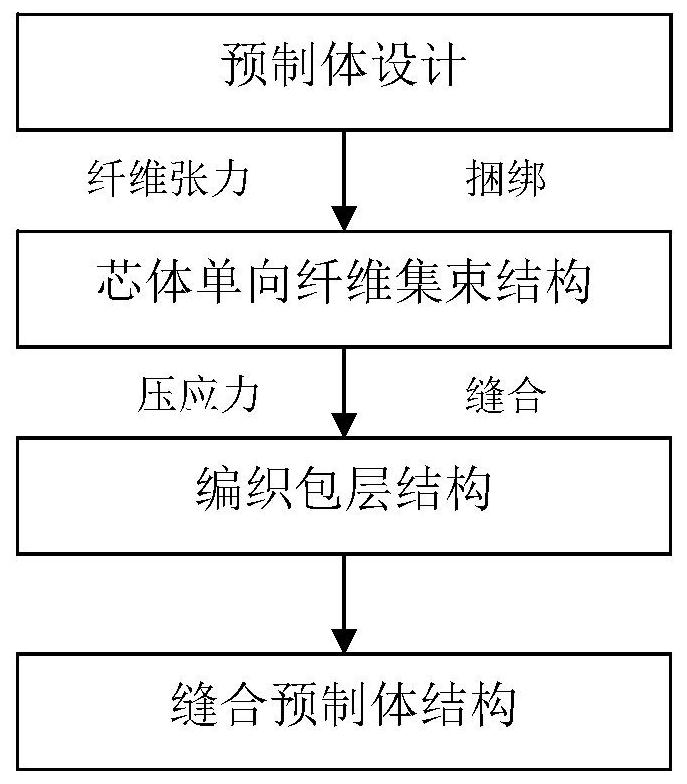

[0059] Such as figure 2 As shown, this embodiment prepares a high aspect ratio rod-shaped preform through the following steps:

[0060] Step 1: Prefabricated body design;

[0061] According to the size requirements of C / SiC ceramic matrix composite bolts, the carbon fiber prefabricated body is designed to be composed of a core structure and a cladding structure, wherein the core structure is a cylinder formed by multiple carbon fiber bundles arranged in the same direction; the cladding structure It ...

Embodiment 2

[0071] from Figure 4 It can be seen that the high aspect ratio rod-shaped preform in this embodiment is composed of a core structure 1 and a cladding structure 2, wherein the core structure 1 is a cylinder formed by a plurality of fiber bundles arranged in the same direction; the cladding structure 2 It is a tubular fiber bundle braided layer woven by a three-dimensional four-way braiding method, which is sewn on the outer peripheral surface of the core structure. The aspect ratio is about 100-200.

[0072] In this example, a high aspect ratio rod-shaped preform is prepared through the following steps:

[0073] Step 1: Prefabricated body design;

[0074] According to the size requirements of C / SiC ceramic matrix composite bolts, the carbon fiber prefabricated body is designed to be composed of a core structure and a cladding structure, wherein the core structure is a cylinder formed by multiple carbon fiber bundles arranged in the same direction; the cladding structure It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com