Production method for cold-rolled IF steel with high surface cleanliness

A production method and cleaning technology, applied in the direction of workpiece cleaning device, workpiece surface treatment equipment, metal rolling, etc., can solve the problem that it is difficult to obviously improve the cleanliness of finished strip steel, cannot meet the production requirements of high-cleanliness cold-rolled IF steel, Unstable production and other issues, to achieve significant economic benefits and brand benefits, low overall manufacturing costs, mature and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

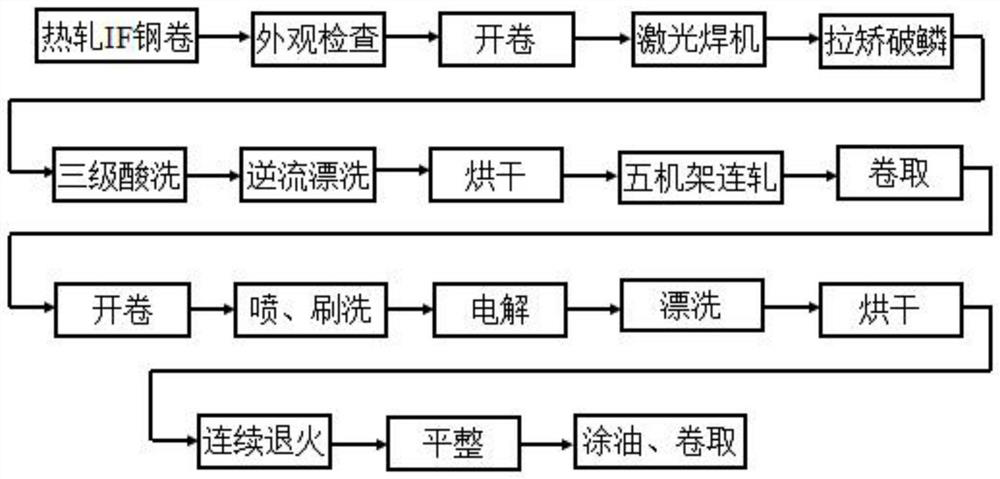

Method used

Image

Examples

Embodiment 1

[0046] In this example 1, the target IF steel for a production schedule is 500 tons in total, the thickness of the finished cold-rolled steel strip is 0.65-0.80mm, and the width is 1450-1780mm; The reflectivity is 92.2-93.1%, and the finished steel strips all meet the requirements of customers for high-end automobiles and household appliances.

[0047] The production steps of embodiment 1 are as follows:

[0048] (1) After the hot-rolled IF steel coil is uncoiled and welded, the scale is broken by tension leveling, the elongation rate of tension leveling is 1.7-1.9%, and the insertion depths of 1# and 2# bending rolls and straightening rolls are 30mm, 23mm and 11mm respectively;

[0049] (2) Carry out continuous shallow tank turbulent flow hydrochloric acid pickling to the strip steel, the pickling temperature is 80-82°C, the free acid concentration in 3# acid tank is 179g / L, the pickling speed is 120m / min, and the surface is free from under-pickling or Pickling;

[0050] (3...

Embodiment 2

[0060] In this example 2, the target IF steel for a production schedule is 500 tons in total, the thickness of the cold-rolled finished strip is 0.65-0.80mm, and the width is 1550-1850mm; the strips produced in batches all have good surface cleanliness. The reflectivity is 92.0-92.6%, and the finished steel strips all meet the requirements of customers for high-end automobiles and household appliances.

[0061] The production steps of embodiment 2 are as follows:

[0062] (1) After the hot-rolled IF steel coil is uncoiled and welded, the scale is broken by tension leveling, the elongation rate of tension leveling is 1.5-1.8%, and the insertion depths of 1# and 2# bending rolls and straightening rolls are 28mm, 21.5mm and 12mm respectively;

[0063] (2) Carry out continuous shallow tank turbulent flow hydrochloric acid pickling to the strip steel, the pickling temperature is 80~82°C, the free acid concentration in 3# acid tank is 169g / L, the pickling speed is 140m / min, and ther...

Embodiment 3

[0074] In Example 3, a total of 500 tons of IF steel is targeted for production scheduling, and the finished cold-rolled steel strip has a thickness of 0.65-0.80 mm and a width of 1000-1500 mm; the strips produced in batches all have good surface cleanliness. The reflectivity is 92.2-93.0%, and the finished steel strips all meet the requirements of customers for high-end automobiles and household appliances.

[0075] The production steps of embodiment 3 are as follows:

[0076] (1) After the hot-rolled IF steel coil is uncoiled and welded, the scale is broken by tension leveling, the elongation rate of tension leveling is 1.5-2.0%, and the insertion depths of 1# and 2# bending rollers and straightening rollers are 30mm, 23mm and 11mm respectively;

[0077] (2) Carry out continuous shallow tank turbulent flow hydrochloric acid pickling to the strip steel, the pickling temperature is 75~78°C, the free acid concentration in the 3# acid tank is 190g / L, the pickling speed is 150m / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com