Heterojunction type Fenton-like catalyst and preparation method thereof, and special system and method

A catalyst and heterojunction technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve unsatisfactory effects of fluorine-containing wastewater, low concentration that can be treated by adsorption method, and sludge Problems such as high moisture content, to achieve the effect of facilitating transfer, promoting effective decomposition, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

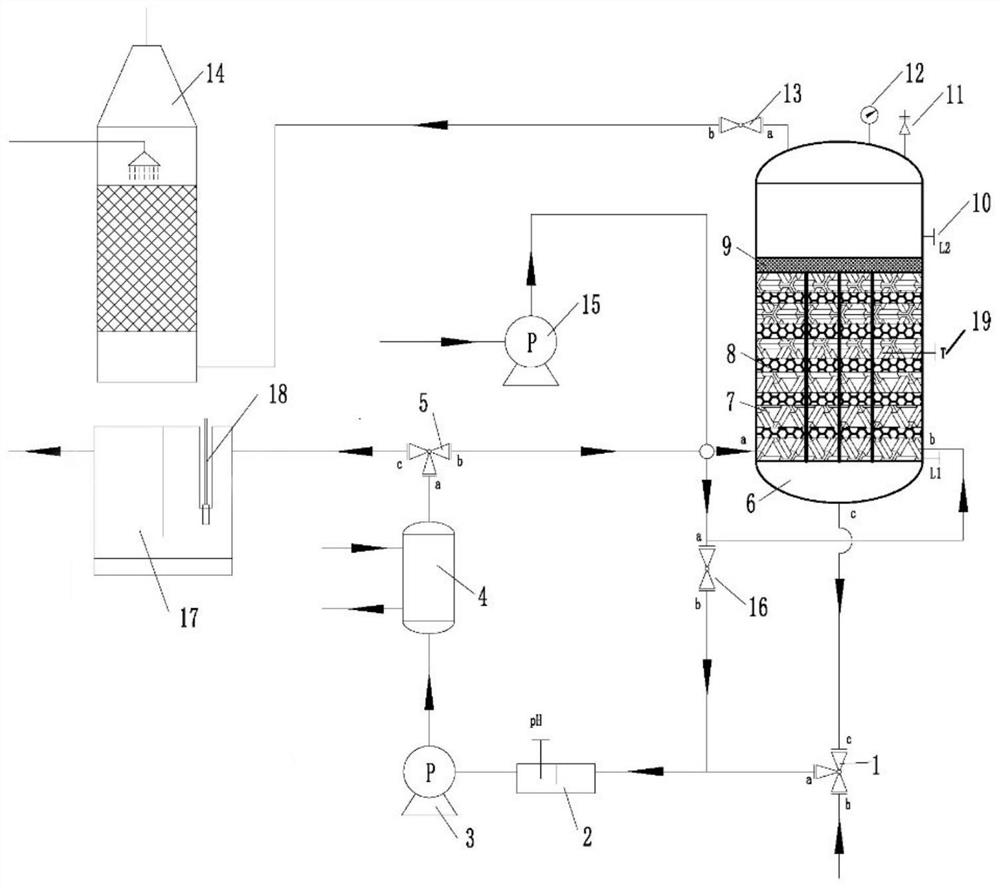

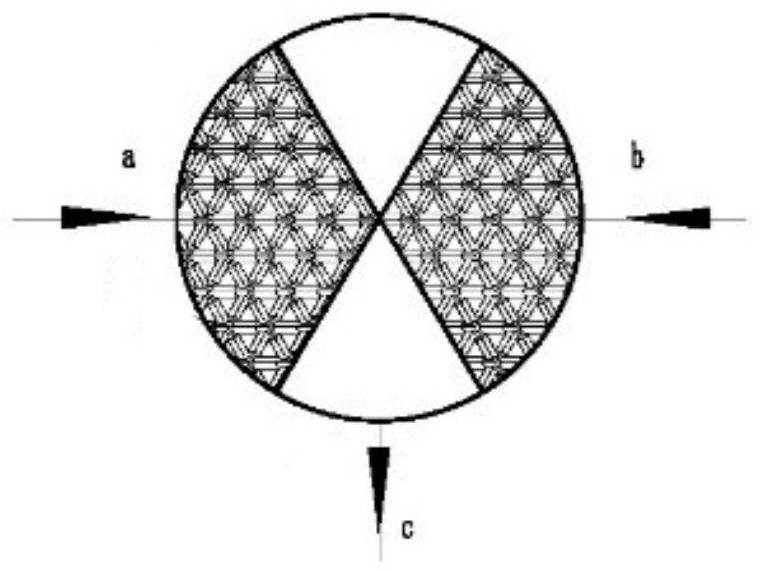

[0045] like figure 1 As shown, the dedicated system for catalyst degradation of high COD fluorine-containing wastewater includes a reaction module, a heat exchange module, a precipitation module, and an exhaust gas absorption module. The reaction module includes a reaction tank 6, wherein the top of the reaction tank 6 is provided with a safety valve 11, a pressure gauge 12 and an exhaust valve 13, and the inside of the reaction tank 6 is divided into two catalytic reaction zones a and b and an outlet zone c. Area c is divided into two parts, and the tops of area a and area b of the catalytic reaction area communicate with both parts of area c. The two catalytic reaction zones of the reaction tank 6 are provided with alternately stacked catalyst filling areas 7 and θ rings 8. The interior of the reaction tank 6 is divided into two catalytic reaction zones. The upper part is provided with a demister 9. The side of the reaction tank 6 The wall is provided with a liquid level se...

Embodiment 2

[0057] (1) LaFe 0.7 Cu 0.3 o 3 preparation of

[0058] According to the molar ratio of 1:0.7:0.3, weigh 2.1650 g of lanthanum nitrate hexahydrate, 1.4140 g of iron nitrate nonahydrate, and 0.3624 g of copper nitrate trihydrate, and dissolve them in 10 mL of distilled water to obtain liquid A. According to the total molar ratio of lanthanum, iron, copper metal ions and maleic acid molar ratio of 1:1.3, weigh 1.5089g maleic acid and 0.05g Z-type foaming agent and dissolve them in 40mL distilled water to obtain liquid B. Add it dropwise to liquid A at a flow rate of 0.5mL / min, and stir the whole dropping process in a water bath at 80°C. React until a sol-gel form is formed, dry the resulting gel in a blast drying oven at 80°C overnight, grind to obtain a precursor powder, then raise the temperature of the precursor powder to 600°C at 5°C / min, keep it warm for 2 hours, and continue to heat at 5°C Raise the temperature to 800°C per minute, keep it warm for 2 hours, and obtain m...

Embodiment 3

[0068] (1) LaFe 0.5 Cu 0.5 o 3 preparation of

[0069] According to the molar ratio of 1:0.5:0.5, weigh 2.1650 g of lanthanum nitrate hexahydrate, 1.0100 g of iron nitrate nonahydrate, and 0.6040 g of copper nitrate trihydrate, and dissolve them in 10 mL of distilled water to obtain liquid A. According to the total molar ratio of lanthanum, iron and copper metal ions to citric acid molar ratio of 1:1.2, weigh 2.5217g of citric acid and 0.05g of G-type foaming agent and dissolve them in 40mL of distilled water to obtain liquid B. Add dropwise to liquid A at a flow rate of mL / min, and the entire dropping process is carried out with stirring in a water bath at 80°C. React until a sol-gel form is formed, dry the resulting gel in a blast drying oven at 85°C overnight, grind to obtain a precursor powder, then raise the temperature of the precursor powder to 600°C at 5°C / min, keep it warm for 2 hours, and then continue for 5 ℃ / min to 800 ℃, heat preservation for 2h, after natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com