Desulfurization and denitrification solid particles as well as preparation method and application thereof

A solid particle, desulfurization and denitrification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large loss, difficult recovery, and low strength of desulfurization and denitrification agents, so as to promote oxidation and improve removal capacity , the effect of high breakthrough sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

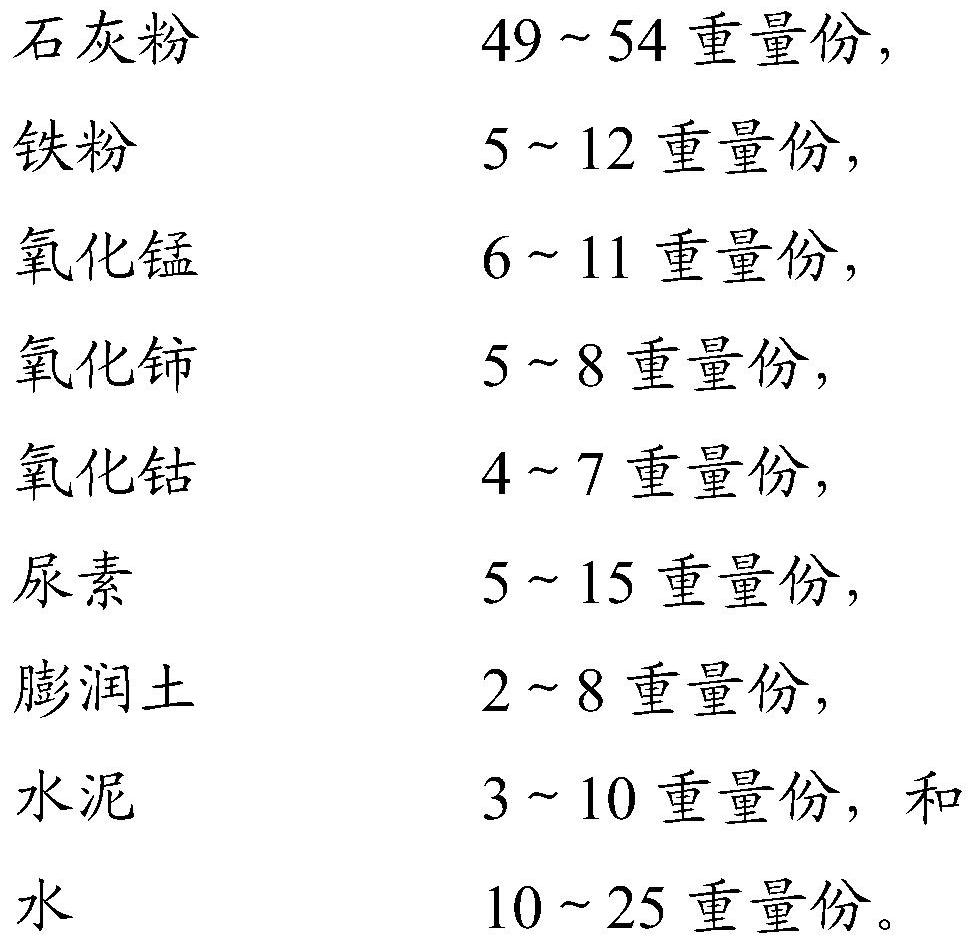

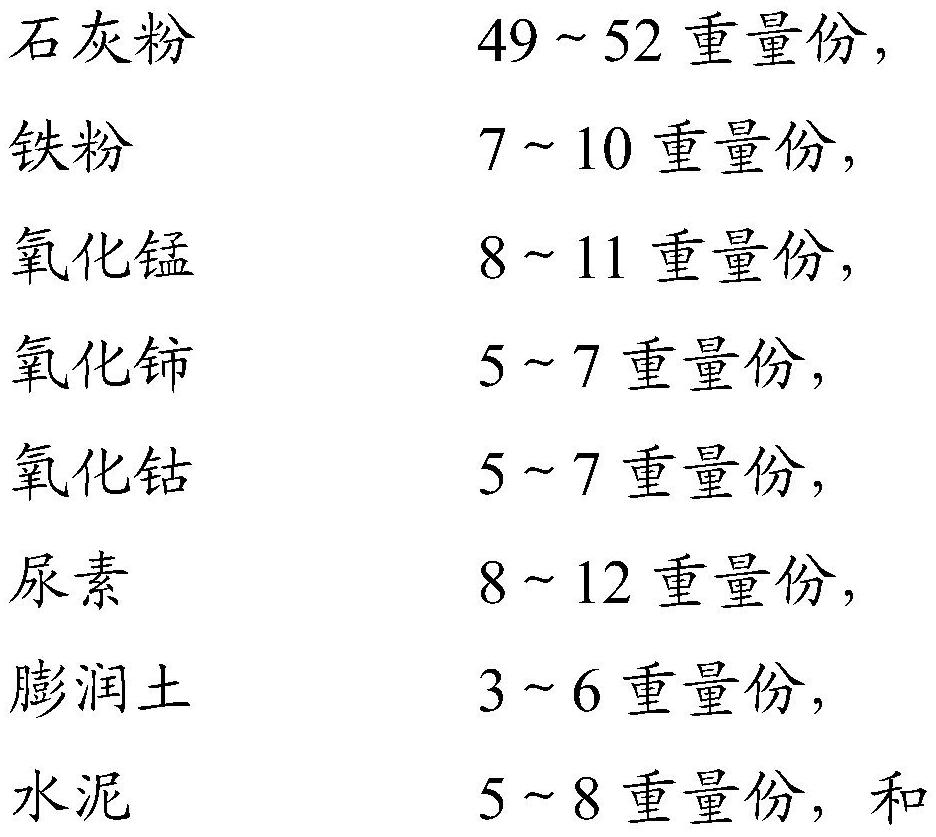

[0037]

[0038] The preparation method comprises the steps of: lime, iron, manganese oxide, cerium oxide, cobalt oxide, urea, bentonite and cement mix, then mixed with water, granulation, drying, desulfurization and denitrification to obtain solid particles. Amounts of raw materials as previously described, are not repeated here.

[0039] Lime powder, iron oxide, manganese oxide, cerium oxide, cobalt oxide, urea, bentonite and the cement mixing process may be carried out in a kneader. The mixing time is 10 ~ 30min; preferably 10 ~ 20min; more preferably 15 ~ 20min.

[0040] Other raw materials mixed with water may be carried out in a kneader. Water can be divided into multiple additions. E.g. 2 to 5 times; preferably, water was added three times. The mixing time may be 20 ~ 50min; preferably 25 ~ 40min; more preferably 30 ~ 40min. This is conducive to improve the desulfurization and denitration strength of the solid particles.

[0041] Granulation can be carried out in the granul...

Embodiment 1~6 and comparative example 1~8

[0055] The lime powder, 8 parts by weight of iron, manganese oxide, cerium oxide, cobalt oxide, 10 parts by weight of urea, 4 parts by weight of bentonite and 6 parts by weight of cement in the mixing kneader in 15min. 15 parts by weight of the average added in three portions of deionized water, mixed 30min. In granulated in a granulator, dried in an oven 3h, cooled to obtain solid particles desulfurization and denitration. Desulfurization and denitrification of solid particles is cylindrical, having a diameter of 5 ~ 10mm, a length of 8 ~ 15mm. Specific conditions were as shown in Table 1, the solid particles desulfurization and denitration performance as shown in Table 2.

[0056] Table 1

[0057]

[0058] Table 2

[0059]

[0060] Difference between Examples 1-3 and Comparative Examples 1-2 is that different amounts of manganese oxide. As apparent from Table 2, the desulfurization and denitrification of solid particles and sulfur capacity penetration penetration nitrate con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com