Mesoporous silica prodrug nanoparticle for combined photothermal therapy and chemotherapy, and preparation method and application thereof

A technology of mesoporous silica and nanoparticles, which is applied in the field of biomedical nanomaterials, can solve the problems of drug burst release and weak force, and achieve the effect of improving burst release, release acceleration, and good drug loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

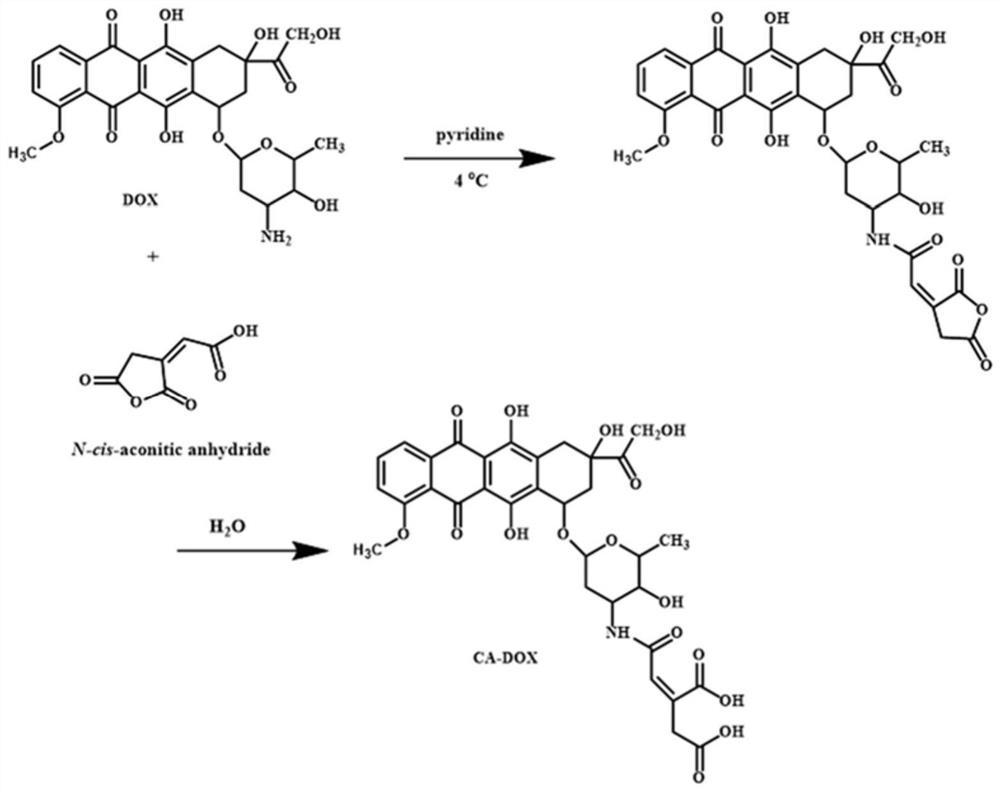

Method used

Image

Examples

Embodiment 1

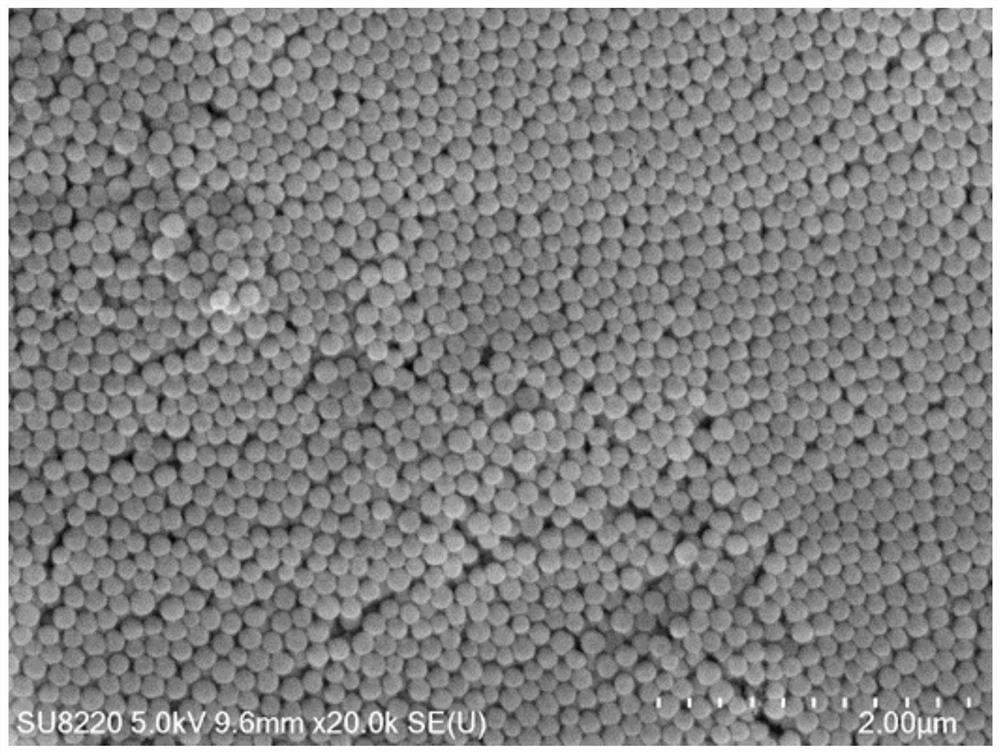

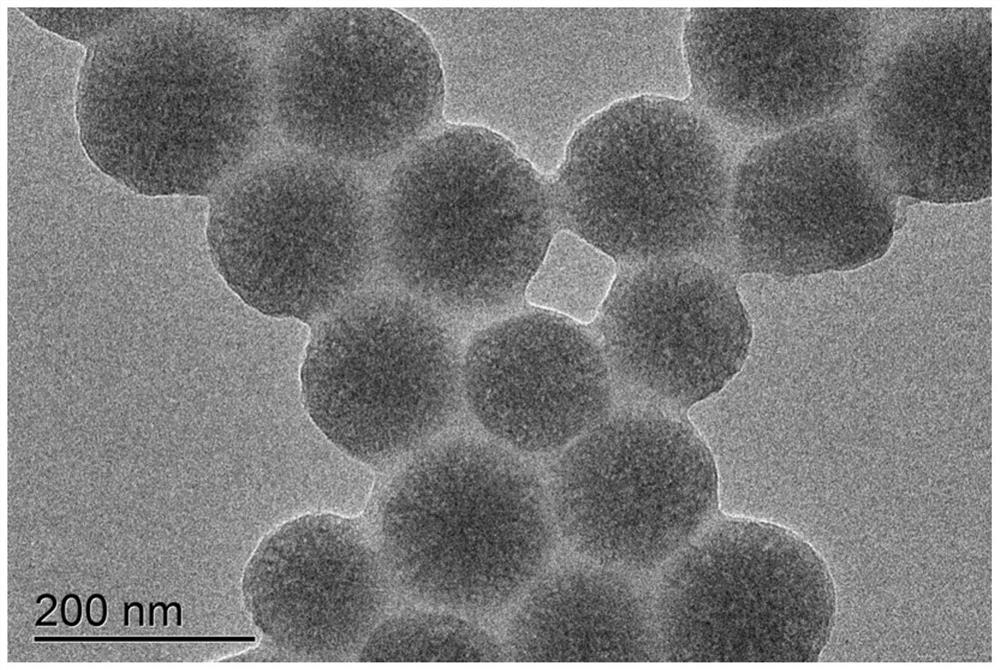

[0072] (1) Preparation of mesoporous silica containing surfactant: take 0.2 parts by mass of CTAB, 0.2 parts by mass of FC 2 , 0.018 parts by mass of NaOH and 96 parts by volume of water were mechanically stirred for 0.5 h, then 1.0 parts by volume of ethyl orthosilicate was quickly added, the temperature was raised to 80° C., and the reaction was continued for 2 h. After the reaction was completed, it was naturally cooled to room temperature, centrifuged at 10,000 rpm, washed with water several times, and vacuum-dried at 30°C for 24 hours to obtain a white powder (MSN@CTAB).

[0073] The parts by weight of reactant in the described step (1) are as follows: 0.20 part of CTAB; 0.2 part of FC 2 ; 0.018 parts of sodium hydroxide; 0.96 parts of TEOS; 98.78 parts of water.

[0074] (2) Preparation of surface aminated mesoporous silica: disperse 0.5 parts by mass of MSN@CTAB in 20 parts by volume of anhydrous toluene, N 2 Reflux at 80°C for 2 hours, add 0.75 parts by volume of sil...

Embodiment 2

[0095] (1) Preparation of mesoporous silica containing surfactant: take 0.15 parts by mass of CTAB, 0.15 parts by mass of FC 2 , 3.75 parts by volume of TEOA solution and 96 parts by volume of water were mechanically stirred for 0.5 h, then 1.0 parts by volume of ethyl orthosilicate was quickly added, the temperature was raised to 80° C., and the reaction was continued for 2 h. After the reaction was completed, it was naturally cooled to room temperature, centrifuged at 10,000 rpm, washed with water several times, and vacuum-dried at 30°C for 24 hours to obtain a white powder (MSN@CTAB).

[0096] The parts by weight of reactant in described step (1) are as follows: 0.15 part of CTAB; 0.15 part of FC 2 ; 0.06 parts TEOA; 0.95 parts TEOS; 98.78 parts water.

[0097] (2) Preparation of surface aminated mesoporous silica: disperse 0.6 parts by mass of MSN@CTAB in 20 parts by volume of anhydrous toluene, N 2 Reflux at 80°C for 2 hours, add 0.5 parts by volume of silane coupling a...

Embodiment 3

[0109] (1) Preparation of mesoporous silica containing surfactant: take 0.25 parts by mass of CTAB, 0.25 parts by mass of FC 2 , 2.5 parts by volume of ammonia water and 96 parts by volume of water were mechanically stirred for 0.5 h, then 1.0 parts by volume of ethyl orthosilicate was quickly added, the temperature was raised to 80° C., and the reaction was continued for 2 h. After the reaction was completed, it was naturally cooled to room temperature, centrifuged at 10,000 rpm, washed with water several times, and vacuum-dried at 30°C for 24 hours to obtain a white powder (MSN@CTAB).

[0110] The parts by weight of reactant in described step (1) are as follows: 0.25 part of CTAB; 0.25 part of FC 2 ; 0.10 parts of ammonia; 0.95 parts of TEOS; 98.78 parts of water.

[0111](2) Preparation of surface aminated mesoporous silica: disperse 0.5 parts by mass of MSN@CTAB in 20 parts by volume of anhydrous toluene, N 2 Reflux at 80°C for 2 hours, add 1.0 volume parts of silane cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com