Heat dissipation structure capable of regulating and controlling flow in partitioned manner and preparation method of heat dissipation structure

A technology of heat dissipation structure and heat dissipation unit, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of difficulty in using embedded microfluidic heat dissipation structure, increase system complexity, etc., to strengthen cooling performance, improve Utilization rate, the effect of improving energy consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides a preparation method for the above-mentioned heat dissipation structure, which includes the following steps.

[0066] Firstly, a cover plate structure comprising a first heat dissipation unit array is prepared, so that each of the first heat dissipation units is provided with an embedded micro-channel.

[0067] The embedded micro-channel can be formed according to the design of the embedded micro-channel of the first heat dissipation unit as described above.

[0068] In a specific embodiment, the cover plate structure is integrally formed, and the entire substrate is processed by a photolithography process, an etching process, a milling process, an etching process or a combination thereof, so as to obtain the The cover plate structure of the cell array. The substrate can be a material with high thermal conductivity, such as silicon, diamond, metal (such as copper), and the like.

[0069] In another specific embodiment, the cover pla...

Embodiment 1

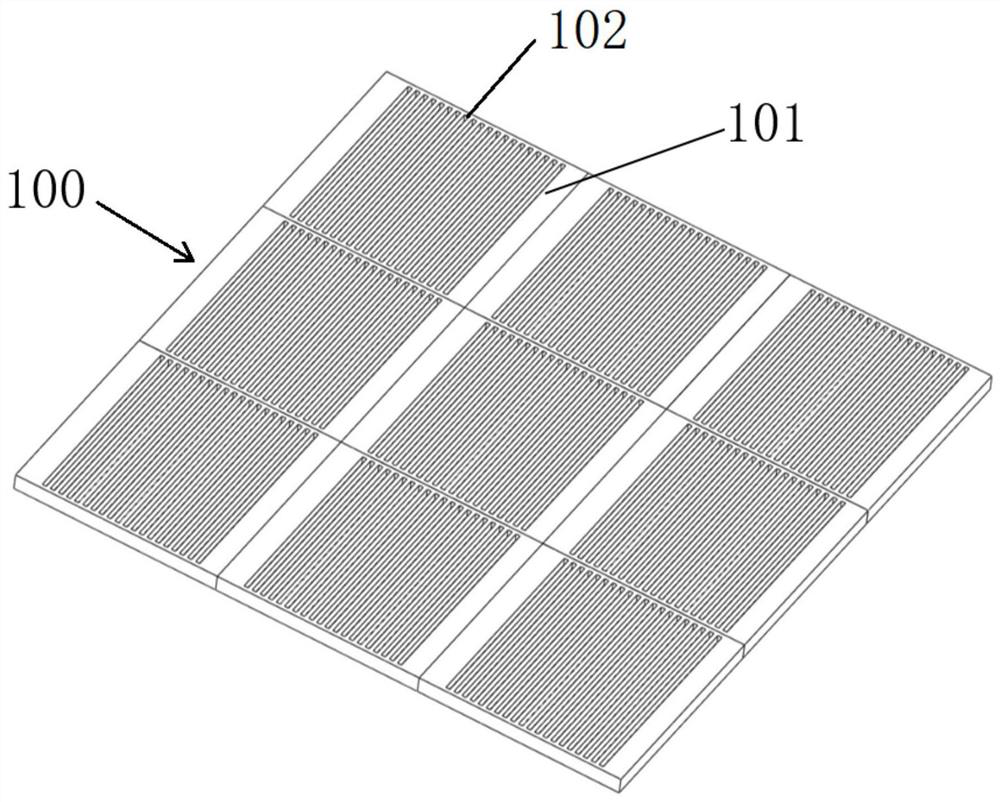

[0083] First, the heat dissipation area of the heat source is divided into 3*3 sub-areas, and the first heat dissipation unit array is designed according to these sub-areas, wherein the area of the first heat dissipation unit 101 is 5mm*5mm, and the embedding in each first heat dissipation unit 101 The micro-channels 102 are independent of each other and have the same structural features. Then, the embedded micro-channel 102 is formed on the copper plate by milling cutter processing technology, so as to obtain the cover plate structure 100, such as figure 1 shown.

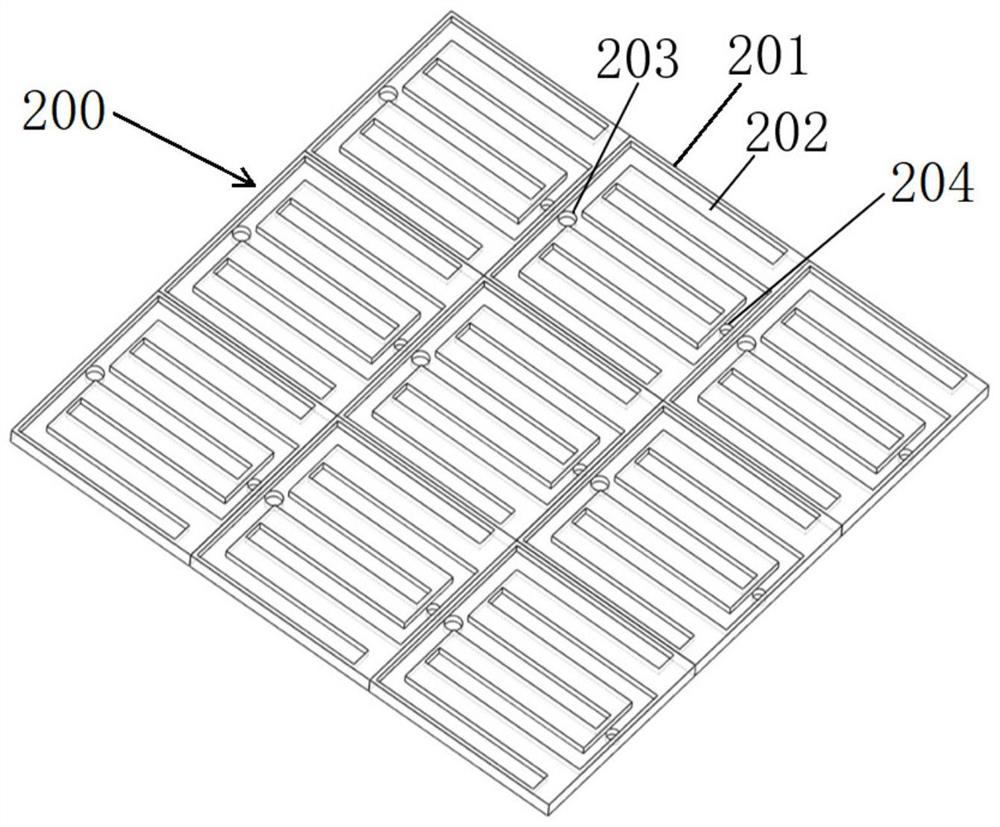

[0084] The second heat dissipation unit array is formed on the copper plate by using milling cutter processing technology and drilling technology, so as to obtain the bottom plate structure 200, as shown in figure 2 As shown, the second heat dissipation unit 201 includes a manifold channel 202 , a liquid inlet 203 and a liquid outlet 204 , and the manifold channels 202 in each second heat dissipation unit 201...

Embodiment 2

[0088] Carry out according to the method for embodiment 1, difference is:

[0089] 1) The structural features of the embedded micro-channel 102 of the first heat dissipation unit 101 located in the center of the first heat dissipation unit array are minimized so as to increase the convective heat transfer coefficient and enhance the local cooling capacity. The obtained cover plate structure 100 is as follows Figure 4 shown;

[0090] 2) Make the manifold passage 202 structural feature (ie width) of the second heat dissipation unit 201 located in the center of the second heat dissipation unit array the smallest, and the number of manifold passages is the largest; make the second heat dissipation unit located at the four corners of the second heat dissipation unit array The structural characteristics of the manifold channels are the largest, and the number of manifold channels is the least. The resulting base plate structure 200 is as follows Figure 5 shown;

[0091] 3) After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com