Packaging resin composition for surface acoustic wave device, laminated body, and preparation method

A technology of encapsulating resin and surface acoustic wave, applied in the direction of synthetic resin layered products, lamination devices, chemical instruments and methods, etc., can solve the problem of deteriorating surface acoustic wave filter insertion loss, unable to meet the heat dissipation requirements of electronic devices, packaging materials Poor shielding performance and other issues, to achieve the effect of improving electromagnetic shielding characteristics, improving power tolerance, and excellent heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

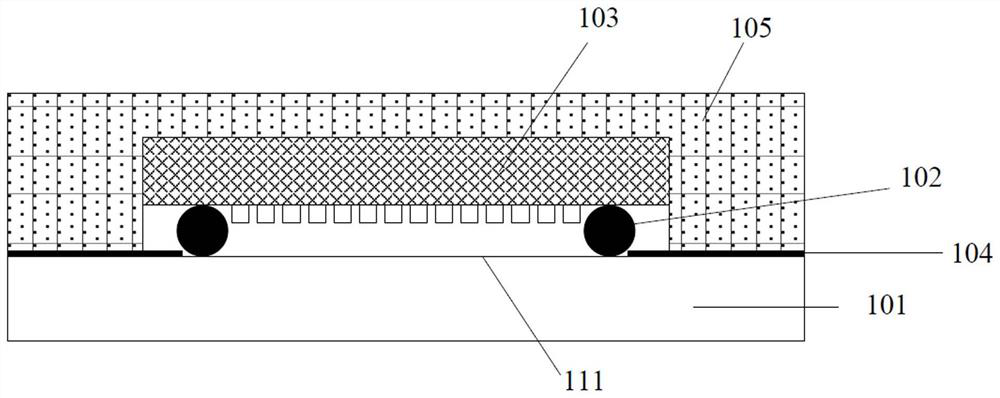

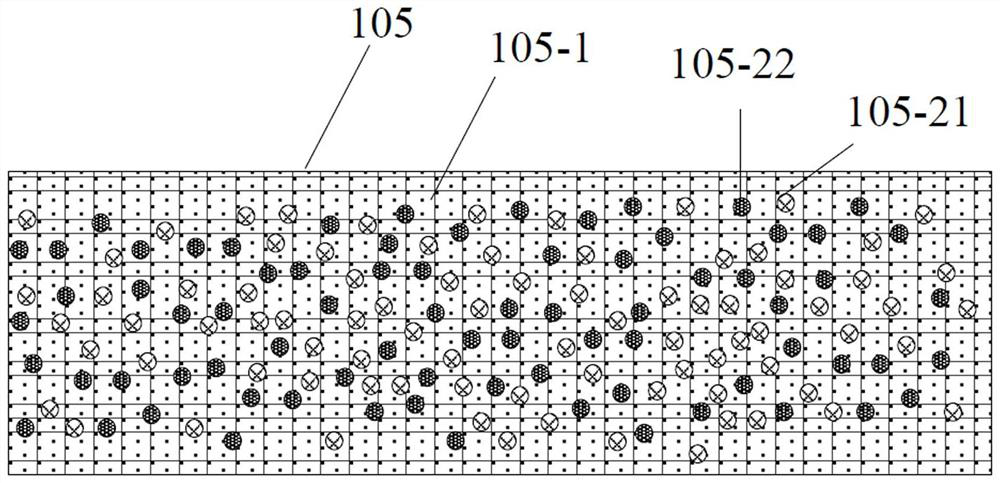

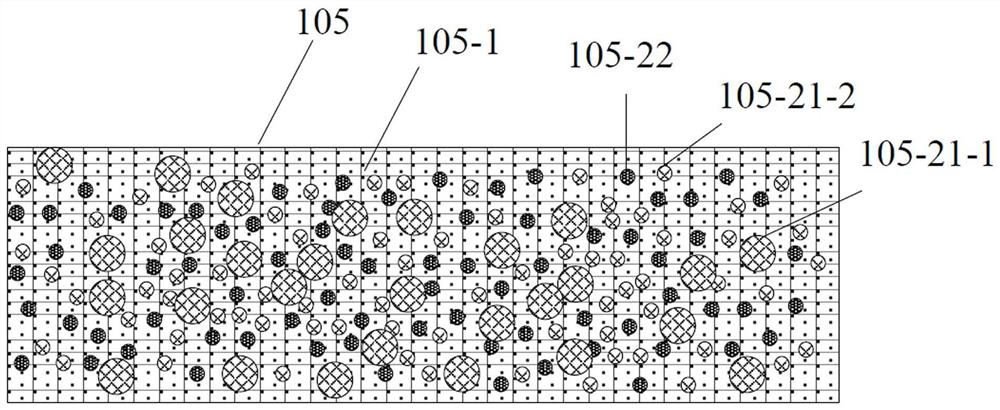

[0053] Such as figure 2 with Figure 4 As shown, the packaging resin composition (105) involved in this embodiment includes: a resin matrix (105-1) and a filler, wherein the resin matrix includes epoxy resin and epoxy resin curing agent, and the filler includes a thermally conductive filler (105 -21) and shielding filler (105-22), the thermal conductivity of the thermally conductive filler at 25°C exceeds 2W / (m·K), and the electrical conductivity of the shielding filler at 25°C exceeds 10 2 S / m, the mass percentage of the shielding filler and the thermal conductive filler in the encapsulation resin composition is 40-70%.

[0054] The thermal conductivity of the above-mentioned encapsulating resin composition and thermally conductive filler was measured at a temperature of 25° C. using a thermal conductivity meter.

[0055] The shielding performance of the above packaging resin composition is measured based on the near-field shielding effectiveness method in the frequency rang...

Embodiment 2

[0081] The following components of the encapsulation resin composition are by mass percentage:

[0082] (1) Epoxy resin: bisphenol A type epoxy resin, 35%

[0083] (2) Epoxy resin curing agent: acid anhydride, 15%

[0084] (3) Thermally conductive filler: spherical alumina with a particle size of 200nm, 40%

[0085] (4) Shielding filler: dendritic copper powder with a particle size of 500nm, 10%

[0086]First put the epoxy resin, epoxy resin curing agent, thermally conductive filler, and shielding filler into the mixer, and mechanically stir and mix at a speed of 500 rpm for 15 minutes. The above mixture was then put into a twin-screw extruder, melt-extruded and granulated at 150° C. to obtain an encapsulating resin composition for surface acoustic wave devices.

[0087] The performance of the obtained encapsulating resin composition for surface acoustic wave devices is as follows after testing:

[0088] Density: 1.08g / cm 3 ;

[0089] Thermal conductivity: 3.3W / (m·K);

...

Embodiment 3

[0093] The following components of the encapsulation resin composition are by mass percentage:

[0094] (1) Epoxy resin: bisphenol A type epoxy resin, 30%

[0095] (2) Epoxy resin curing agent: acid anhydride, 10%

[0096] (3) Curing catalyst: 5%

[0097] (4) Toughening agent: core-shell structure of styrene-butadiene copolymer coated on the outside of styrene-acrylic block copolymer, particle size is 500nm, 5%

[0098] (5) The first thermally conductive filler: spherical AlN with a particle size of 300nm, 20%

[0099] (6) The second thermally conductive filler: spherical AlN with a particle size of 100nm, 10%

[0100] (7) Shielding filler: dendritic copper powder with a particle size of 500nm, 20%

[0101] First put epoxy resin, epoxy resin curing agent, curing catalyst, toughening agent, first thermally conductive filler, second thermally conductive filler, and shielding filler into a mixer, and mechanically stir and mix at a speed of 500 rpm for 15 minutes. Then the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com