Method and equipment for recovering lithium battery slurry

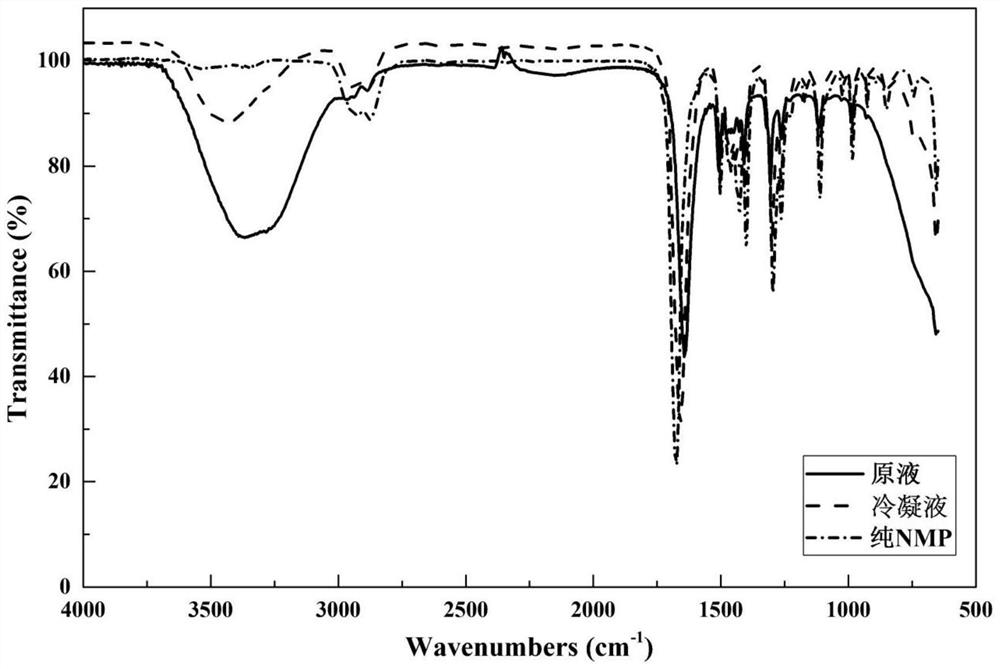

A recycling method and technology for lithium batteries, applied in battery recycling, recycling technology, separation methods, etc., can solve problems such as unfavorable industrial application, poor centrifugal effect, easy introduction of impurities, etc. The effect of NMP purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

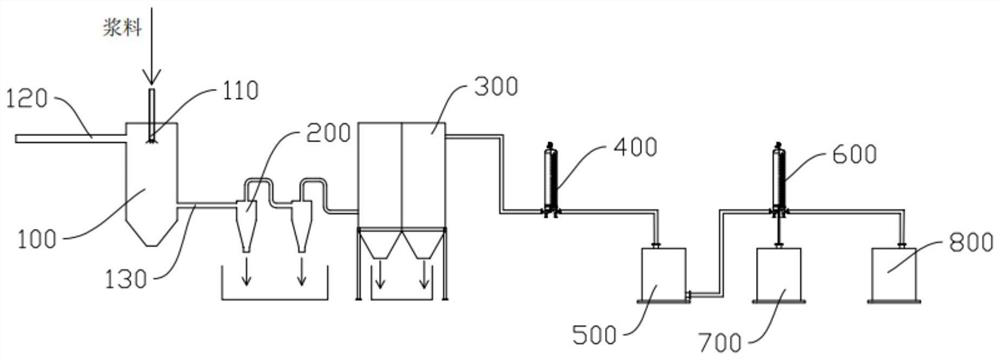

[0035] A centrifugal spray drying system, consisting of a spray chamber 100, two cyclone separators 200, a bag filter 300, a condenser 400, a condensate storage tank 500, a rectification tower 600, an aqueous phase collector 700 and an NMP collector 800 The upper part of the spray chamber 100 is provided with a centrifugal nozzle 110, and the two sides are respectively provided with a hot air inlet 120 and a hot air outlet 130, and the hot air outlet 130 is connected with the inlet of the cyclone separator 200, the cyclone separator 200, the bag filter 300, the condensation The device 400, the condensate storage tank 500 and the rectification column 600 are connected in sequence.

[0036] A kind of recovery method that contains NMP waste lithium battery slurry, concrete steps are as follows:

[0037] S1: Take 1000L NMP waste slurry and use a dual-shaft crusher with a knife distance of 50mm for coarse crushing at a speed of 100r / min. Take the NMP waste slurry and put it in a ba...

Embodiment 2

[0041] A centrifugal spray drying system, consisting of a spray chamber 100, two cyclone separators 200, a bag filter 300, a condenser 400, a condensate storage tank 500, a rectification tower 600, an aqueous phase collector 700 and an NMP collector 800 The upper part of the spray chamber 100 is provided with a centrifugal nozzle 110, and the two sides are respectively provided with a hot air inlet 120 and a hot air outlet 130, and the hot air outlet 130 is connected with the inlet of the cyclone separator 200, the cyclone separator 200, the bag filter 300, the condensation The device 400, the condensate storage tank 500 and the rectification column 600 are connected in sequence.

[0042] A kind of recovery method that contains NMP waste lithium battery slurry, concrete steps are as follows:

[0043] S1: Take 1000L NMP waste slurry and use a dual-shaft crusher with a knife distance of 10mm for coarse crushing at a speed of 500r / min. Take the NMP waste slurry and put it in a ba...

Embodiment 3

[0047] A centrifugal spray drying system, consisting of a spray chamber 100, two cyclone separators 200, a bag filter 300, a condenser 400, a condensate storage tank 500, a rectification tower 600, an aqueous phase collector 700 and an NMP collector 800 The upper part of the spray chamber 100 is provided with a centrifugal nozzle 110, and the two sides are respectively provided with a hot air inlet 120 and a hot air outlet 130, and the hot air outlet 130 is connected with the inlet of the cyclone separator 200, the cyclone separator 200, the bag filter 300, the condensation The device 400, the condensate storage tank 500 and the rectification column 600 are connected in sequence.

[0048] A kind of recovery method that contains NMP waste lithium battery slurry, concrete steps are as follows:

[0049] S1: Take 1000L NMP waste slurry and use a dual-shaft crusher with a knife distance of 30mm for coarse crushing at a speed of 300r / min. Take the NMP waste slurry and put it in a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com