Aluminum-plastic composite bag for food packaging and processing method thereof

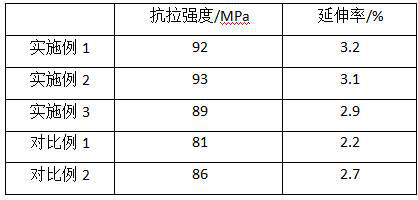

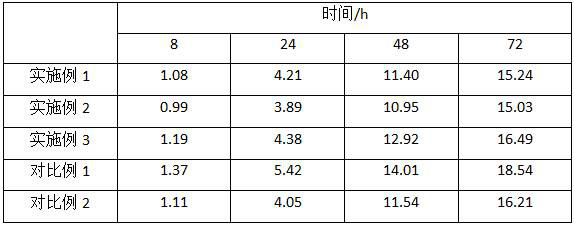

A technology of aluminum-plastic composite and food packaging, which is applied in the direction of chemical instruments and methods, applications, layered products, etc., can solve the problems of low elongation, tensile strength and poor corrosion resistance of aluminum foil, and achieve improved corrosion resistance, Hard to crack and break, the effect of slowing down the migration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The processing method of 1235 double zero foil is:

[0036](1) Melting and casting: According to the mass percentage of the chemical composition of the aluminum alloy strip: Si: 0.086%, Fe: 0.4%, Cu: 0.005%, Mn: 0.005%, Mg: 0.005%, Cr: 0.01%, Zn: 0.0051 %, V: 0.02%, Ti: 0.030%, other individual impurities ≤ 0.01%, total impurities ≤ 0.05%, the balance is Al, the balance is Al for smelting, refining, and casting into ingots, the melting temperature is 755 ±5°C, refining temperature is 695±5°C, casting speed is 60mm / min, water temperature is 25±5°C;

[0037] (2) Sawing and milling: sawing and milling the ingot in step (1), the thickness of the ingot after sawing and milling is 580mm;

[0038] (3) Soaking: The ingot after sawing and milling is heated in two stages, the first stage is kept at 570°C for 8 hours, and the second stage is held at 490°C for 2 hours;

[0039] (4) Hot rolling: After soaking, the ingot is roughly rolled for 16 passes, and the ingot is processed t...

Embodiment 2

[0046] The processing method of 1235 double zero foil is:

[0047] (1) Melting and casting: According to the mass percentage of the chemical composition of the aluminum alloy strip: Si: 0.09%, Fe: 0.43%, Cu: 0.01%, Mn: 0.005%, Mg: 0.01%, Cr: 0.005%, Zn: 0.005 %, V: 0.03%, Ti: 0.013%, other individual impurities ≤ 0.01%, total impurities ≤ 0.05%, the balance is Al, smelting, refining, and casting into ingots, the melting temperature is 755±5℃, The refining temperature is 695±5°C, the casting speed is 60mm / min, and the water temperature is 25±5°C;

[0048] (2) Sawing and milling: sawing and milling the ingot in step (1), the thickness of the ingot after sawing and milling is 560mm;

[0049] (3) Soaking: The ingot after sawing and milling is heated in two stages, the first stage is kept at 580°C for 6 hours, and the second stage is held at 500°C for 1.5 hours;

[0050] (4) Hot rolling: After soaking, the ingot is roughly rolled for 16 passes, and the ingot is processed to a thi...

Embodiment 3

[0057] The processing method of 1235 double zero foil is:

[0058] (1) Melting and casting: according to the mass percentage of the chemical composition of the aluminum alloy strip: Si: 0.10%, Fe: 0.37%, Cu: 0.005%, Mn: 0.01%, Mg: 0.005%, Cr: 0.005%, Zn: 0.01 %, V: 0.025%, Ti: 0.02%, other individual impurities ≤ 0.01%, total impurities ≤ 0.05%, the balance is Al, smelting, refining, and casting into ingots, the melting temperature is 755±5℃, The refining temperature is 695±5°C, the casting speed is 60mm / min, and the water temperature is 25±5°C;

[0059] (2) Sawing and milling: sawing and milling the ingot in step (1), the thickness of the ingot after sawing and milling is 560mm;

[0060] (3) Soaking: The ingot after sawing and milling is heated in two stages, the first stage is kept at 560°C for 9 hours, and the second stage is held at 480°C for 2.5 hours;

[0061] (4) Hot rolling: After soaking, the ingot is roughly rolled 16 times, and the ingot is processed to a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com