Bimetallic FMG desulfurizer for wet oxidation desulfurization

A technology of wet oxidation and desulfurizer, which is applied in combustible gas purification, combustible gas purification/transformation, removal of gas pollutants, etc., can solve the problem of high degradation rate of complex iron desulfurizer, low complex degradation rate The problem of large consumption of chemicals can achieve the effect of good oxidation regeneration, low cost of chemicals, and enhanced utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

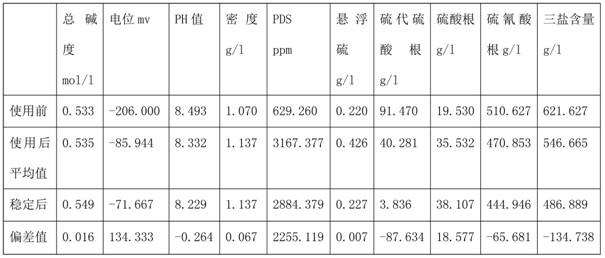

Image

Examples

Embodiment 1

[0032] A bimetallic FMG desulfurizer for wet oxidative desulfurization, prepared from the following raw materials in parts by weight: 1.65 parts of ferrous salt, 0.55 parts of manganese salt, 2.6 parts of organic complexing agent, 2.3 parts of metal corrole, anthraquinone- 2.7—0.5 part of disulfonic acid, 0.5 part of polyethylene glycol, 15 parts of absorbent, 0.1 part of stabilizer, 0.05 part of sedimentation agent, 0.05 part of corrosion inhibitor, and appropriate amount of water.

Embodiment 2

[0034] A bimetallic FMG desulfurizer for wet oxidative desulfurization, prepared from the following raw materials in parts by weight: 3 parts of ferrous salt, 1 part of manganese salt, 8 parts of organic complexing agent, 3.2 parts of metal corrole, anthraquinone- 2.7—2.5 parts of disulfonic acid, 5 parts of polyethylene glycol, 25 parts of absorbent, 2 parts of stabilizer, 0.3 part of sedimentation agent, 1.5 parts of corrosion inhibitor, and appropriate amount of water.

Embodiment 3

[0036] A bimetallic FMG desulfurizer for wet oxidative desulfurization, prepared from the following raw materials in parts by weight: 5 parts of ferrous salt, 2.5 parts of manganese salt, 9 parts of organic complexing agent, 3.8 parts of metal corrole, anthraquinone- 2.7—4.8 parts of disulfonic acid, 15 parts of polyethylene glycol, 40 parts of absorbent, 3 parts of stabilizer, 0.8 part of sedimentation agent, 2.5 parts of corrosion inhibitor, and appropriate amount of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com