Porous zinc alloy bone tissue engineering scaffold coated with bioactive coating and preparation method thereof

A technology of bone tissue engineering and bioactivity, applied in coatings, tissue regeneration, prostheses, etc., can solve the problems of poor bioactivity, insufficient mechanical properties of high-porosity porous zinc alloy scaffolds, etc., and achieve excellent biocompatibility , Accelerate healing, good pore connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

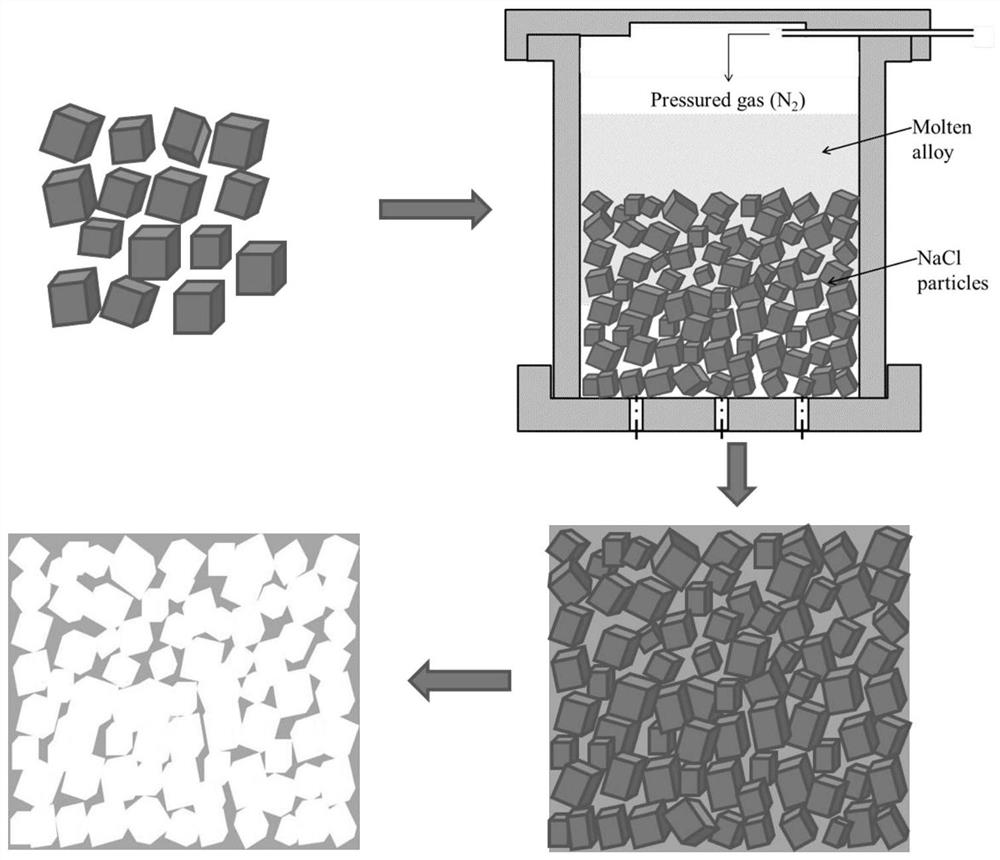

Method used

Image

Examples

Embodiment 1

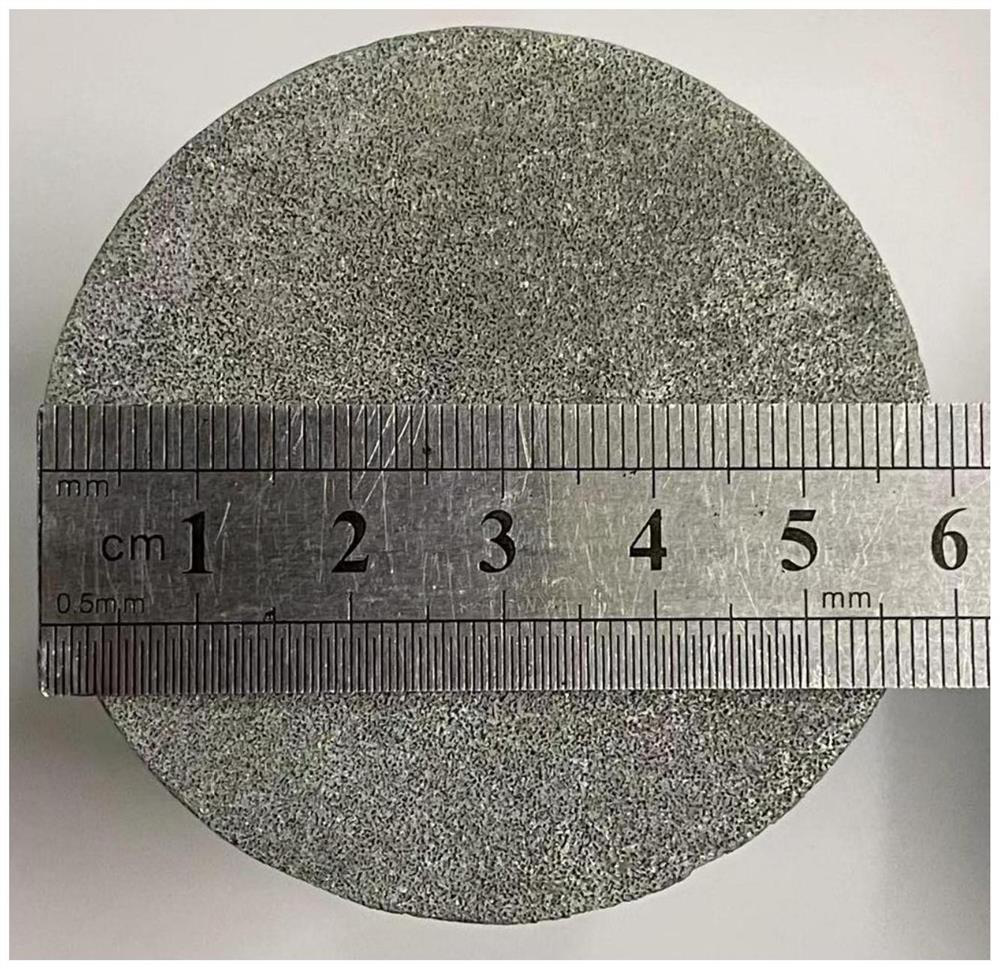

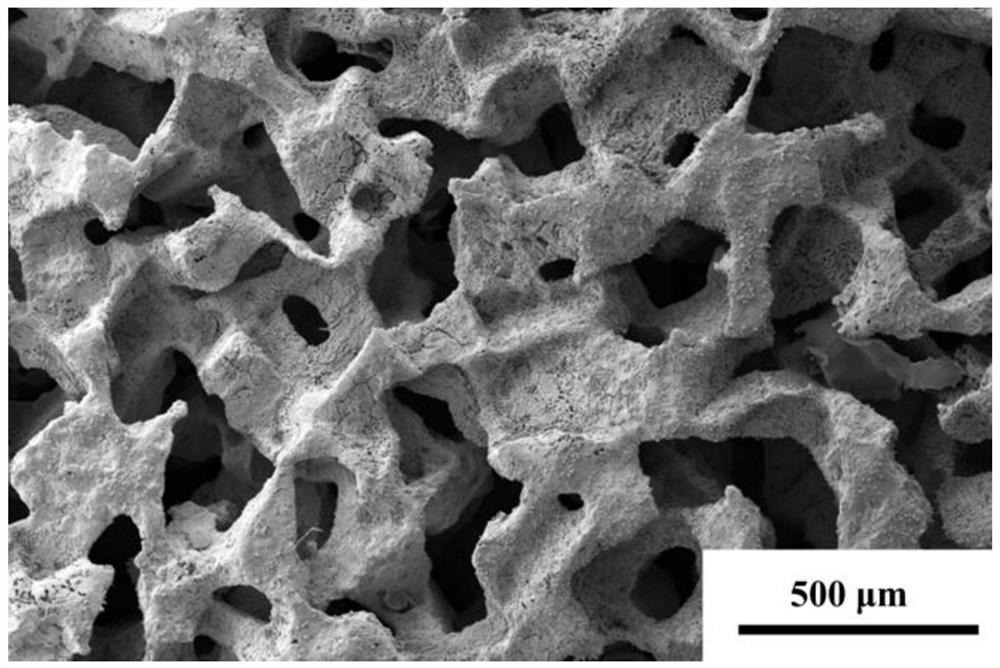

[0030] This embodiment relates to a preparation method of a porous zinc alloy bone tissue engineering scaffold coated with a bioactive coating (pectin coating), the pore size is 100 μm-300 μm, the porosity is 50%-70%, and a zinc-lithium alloy is used (Zn-0.8wt.% Li) as the matrix. image 3 The pore distribution and pore size of the porous zinc alloy are shown, and the porosity of the porous zinc alloy is measured by the drainage method. Specific method: put the cut porous sample (φ6×20mm) into a 25ml measuring cylinder filled with 10ml of water, connect the measuring cylinder to a vacuum machine, and vacuumize for about 5 minutes until all the gas in the porous metal is discharged. At this point, record the volume of water displaced by the porous scaffold (V 2 ). The volume of the porous sample is the volume (V 1 =565.2mm 3 ).

[0031] From this formula the porosity of porous samples can be obtained.

[0032] Specific implementation steps:

[0033] Screening of the pa...

Embodiment 2

[0044] This embodiment relates to a preparation method of a porous zinc alloy bone tissue engineering scaffold coated with a bioactive coating (chitosan coating), the pore size is 500 μm-800 μm, the porosity is 70%-90%, and zinc lithium is used Silver alloy (Zn-0.8wt.%Li-0.5wt.%Ag) was used as the matrix. The porosity of the porous zinc alloy was measured by the drainage method, and the steps were the same as in Example 1.

[0045] Specific implementation steps:

[0046] Screening of the particle size of sodium chloride particles: Pass the sodium chloride particles through 20-mesh and 32-mesh sieves respectively to obtain sodium chloride particles with a particle size ranging from 500 μm to 800 μm. After the screening is completed, dry at 500°C for 2 hours.

[0047] Put 300g of sodium chloride pellets into a mold whose size is Carry out preheating, preheat to 400 ℃ and keep warm. And during this process, the sodium chloride particles are continuously compacted to make the...

Embodiment 3

[0057] This example relates to a preparation method of a porous zinc alloy bone tissue engineering scaffold coated with a bioactive coating (sodium alginate coating), the pore size is 500 μm-800 μm, the porosity is 70%-90%, and zinc lithium is used Manganese alloy (Zn-0.8wt.%Li-0.5wt.%Mn) as the matrix. The porosity of the porous zinc alloy was measured by the drainage method, and the steps were the same as in Example 1.

[0058] Specific implementation steps:

[0059] Screening of the particle size of sodium chloride particles: Pass the sodium chloride particles through 20-mesh and 32-mesh sieves respectively to obtain sodium chloride particles with a particle size ranging from 500 μm to 800 μm. After the screening is completed, dry at 400°C for 6 hours.

[0060] Put 300g of sodium chloride pellets into a mold whose size is Carry out preheating, preheat to 400 ℃ and keep warm. And during this process, the sodium chloride particles are continuously compacted to make the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com