Skin beauty food formula and preparation method of buccal tablets of skin beauty food formula

A technology for skin and food, which is applied in the field of skin beauty food formulations and the preparation of lozenges, which can solve the problems of enhancing the oral mucosa absorption of functional substances, and achieve the effect of avoiding the first-pass effect and prolonging the intake time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

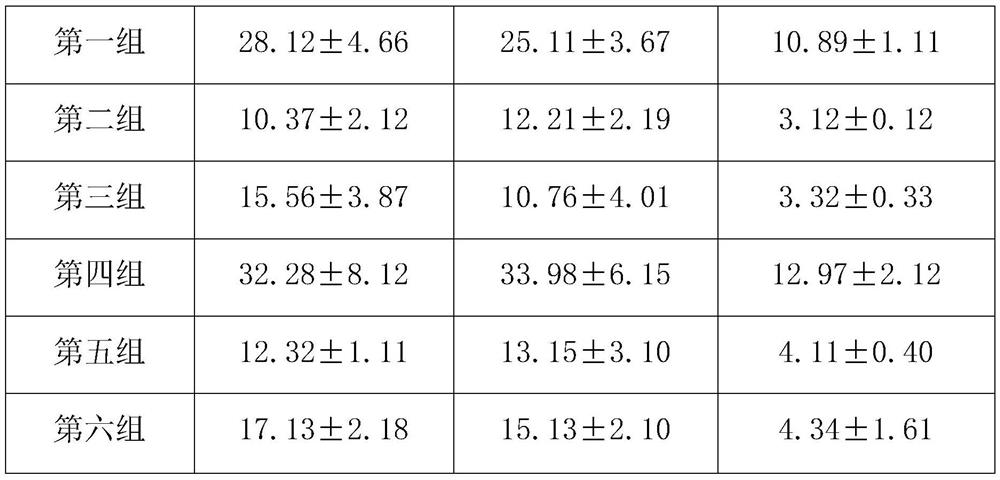

Examples

Embodiment 1

[0023] The content of each component of each 10000 flake skin beauty food is: collagen peptide 3kg, grape seed extract powder 170g, sodium hyaluronate 400g, nicotinamide 15g, vitamin C 100g and coenzyme Q1080g, mannitol 12kg, hydroxyl Propyl methylcellulose 680g, aspartame 68g, magnesium stearate 340g.

[0024] S1. Pass the collagen peptide, grape seed extract powder, sodium hyaluronate, niacinamide, vitamin C and coenzyme Q10 through a 30-80 mesh sieve respectively, and then mix for 20 minutes until uniform to obtain a mixed powder of functional raw materials;

[0025] S2. Pass mannitol, hydroxypropyl methylcellulose and aspartame through a 30-mesh sieve, put them in a wet mixing granulator, set the mixing speed at 1000 rpm, mix for 6 minutes, and then add 50% ethanol as a wetting agent , until the material is completely immersed in it, still set the stirring speed to 1000rpm, and the preparation time to 90s, then set the blast drying oven to 50°C, dry the material until the ...

Embodiment 2

[0036] The content of each component of each 10,000 flake skin beauty food is: collagen peptide 3kg, grape seed extract powder 330g, sodium hyaluronate 800g, nicotinamide 30g, vitamin C 330g and coenzyme Q10160g, mannitol 10kg, hydroxyl Propyl methylcellulose 300g, aspartame 40g, magnesium stearate 100g.

[0037] S1. Pass the collagen peptide, grape seed extract powder, sodium hyaluronate, niacinamide, vitamin C and coenzyme Q10 through a 30-80 mesh sieve respectively, and then mix for 20 minutes until uniform to obtain a mixed powder of functional raw materials;

[0038] S2. Pass mannitol, hydroxypropyl methylcellulose and aspartame through a 30-mesh sieve, put them in a wet mixing granulator, set the mixing speed at 1000 rpm, mix for 6 minutes, and then add 50% ethanol as a wetting agent , until the material is completely immersed in it, still set the stirring speed to 1000rpm, and the preparation time to 90s, then set the blast drying oven to 50°C, dry the material until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com