Constant volume combustion internal combustion engine

A constant volume combustion, internal combustion engine technology, applied in combustion engines, mechanical equipment, machines/engines, etc., can solve the problems of incomplete combustion, low output power, insufficient intake air, etc. The effect of prolonging the air time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

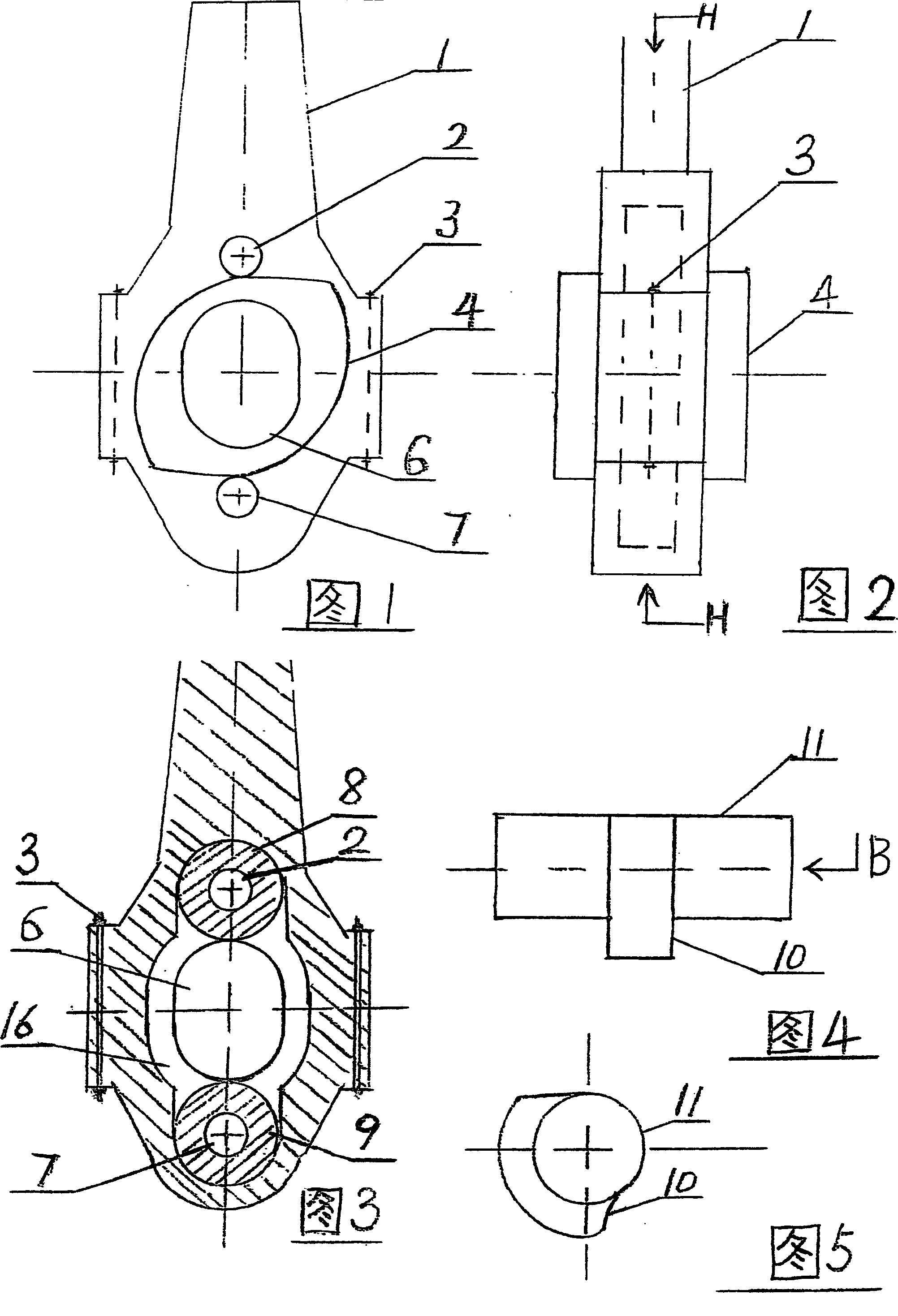

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. For the convenience of description, this structure is described based on the crankshaft connecting rod of a four-stroke motorcycle.

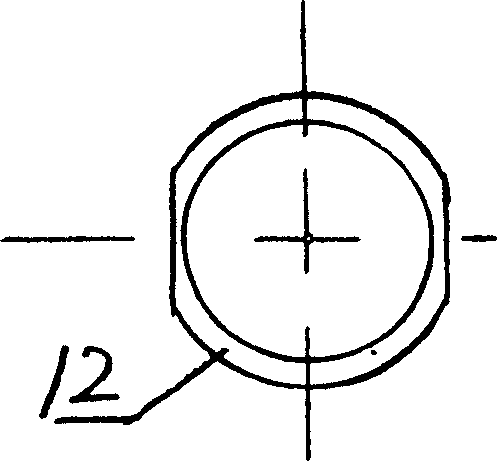

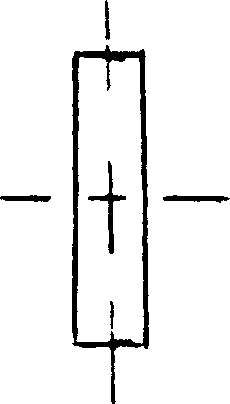

[0033] (1) The concrete way of the present invention is that the both sides of connecting rod big end are processed into the shape of corresponding cam 4, as figure 1 As shown, the crankshaft pin hole 6 on the connecting rod is processed into a long shape, such as figure 1 shown; the middle section of the crank pin 11 is processed into the shape of the cam 10, as Figure 5 As shown; the inside of the connecting rod is processed as image 3 The shape of shown 16 is so that the cam 10 on the crank pin 11 can move freely; two upper and lower bearings 8,9 are also arranged in the connecting rod, which are assembled on the upper and lower two bearing shafts 2,7, as image 3 Shown; also two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com