Bottom-holding protection system with water-saving circulation and for cantilever construction

A protection system and cantilever technology, applied in separation methods, bridges, filtration and separation, etc., can solve the problems of inability to protect water resources, recycling, etc., and achieve the effect of improving construction efficiency, realizing recycling, and achieving remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

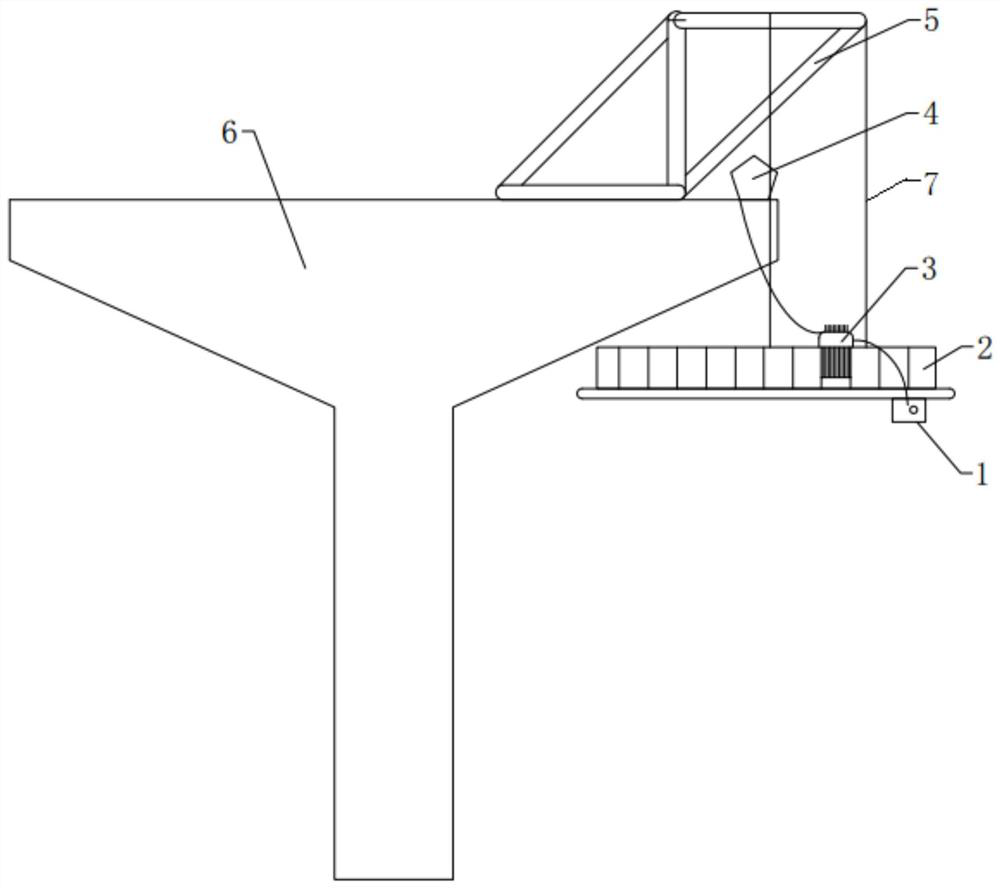

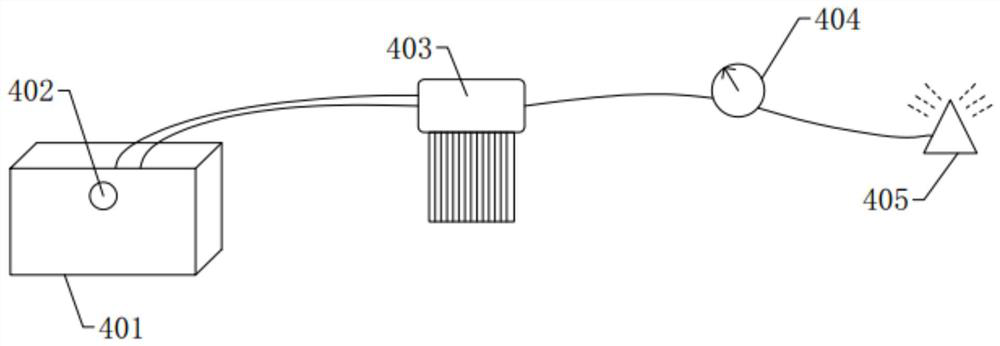

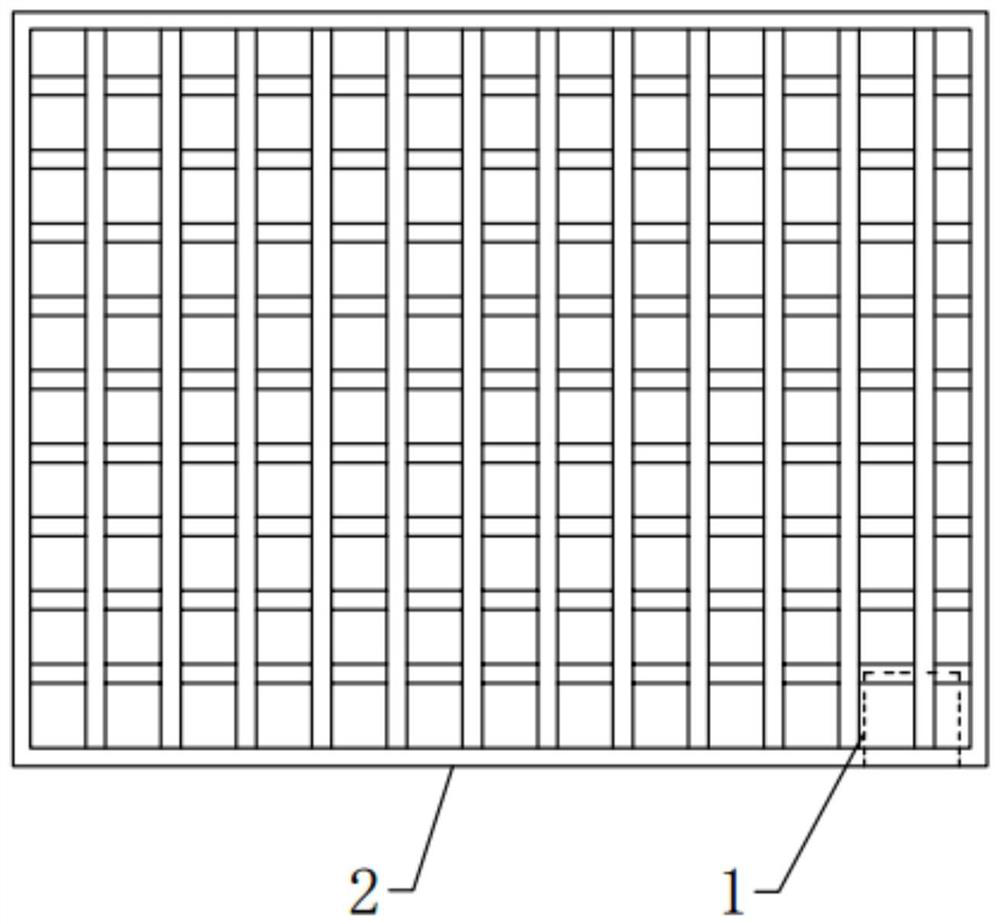

[0036] Such as Figure 1-5 As shown, a bottom protection system with water-saving circulation for cantilever construction includes a bottom protection platform 2 arranged under one side of the pier 6, and the bottom protection platform 2 includes a bottom steel plate 201 and a bottom steel plate 201 fixedly installed The protection plate 202 that is set up vertically all around, the upper surface of described bottom steel plate 201 is the inclined bottom surface 203, and the inner side of described protection plate 202 is fixedly installed with grid plate 204, and described grid plate 204 and bottom steel plate 201 There is a gap on the upper surface, which is set so that when the water left on the surface of the pier 6 falls on the bottom protection platform 2, it can pass through the grid plate 204 and fall on the top of the bottom steel plate 201, between the grid plate 204 and the bottom steel plate 201 The size of the gap is 10-20cm, which can be used to prevent the water...

Embodiment 2

[0050] Such as Figure 1-4 , Image 6 As shown, the difference between this embodiment and the above-mentioned embodiments is only that the mud is filtered in a different manner. In this embodiment, the filtering device includes a support block 103 installed on the inner wall of the water storage tank 1, and the above support block 103 is placed There is a filter housing 104 with an open top, the bottom surface of the filter housing 104 is an inverted cone structure, and the bottom surface of the filter housing 104 is provided with a number of through holes 106, placed inside the filter housing 104 Filter element 105 is arranged, and wherein, filter element 105 is non-woven fabric or sponge, can adopt non-woven fabric or sponge to filter mud earlier when water flows into water storage tank 1 like this, and water then flows from through hole 106 to The water storage tank 1 realizes the filtering effect on the mud. When cleaning, only the non-woven fabric or the sponge needs to...

Embodiment 3

[0052] Such as Figure 1-4 , Figure 7 As shown, the difference between this embodiment and the above-mentioned embodiments is only that the mud is filtered in a different manner. In this embodiment, the filter device includes a filter plate 107 installed vertically inside the water storage tank 1, and the filter plate 107 is used for filtering gauze or non-woven fabric, the bottom of the water storage tank 1 is provided with a downwardly recessed mud collection area 108 for collecting mud, and the mud collection area 108 is arranged on one side of the filter plate 107, so The bottom of the mud collection area 108 is connected with a mud discharge pipe 109. In the actual construction process, the water on the bottom protection platform 2 flows into the position with the mud collection area 108. As the water level rises, the water flows through the filter plate 107 after filtering. On the other side of the filter plate 107, the mud gradually sinks into the position of the mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com