Papermaking filler additive and preparation method thereof

A technology of papermaking fillers and additives, applied in the field of papermaking, can solve the problems of high price, difficulty in recycling titanium dioxide, and limiting the wide application of titanium dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

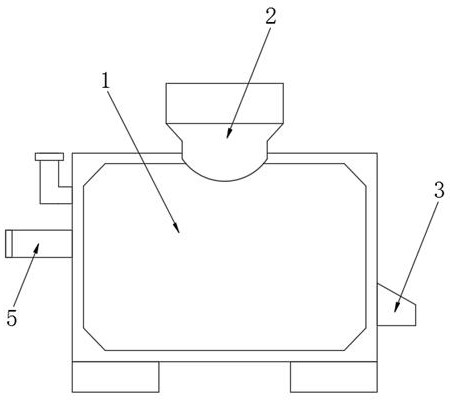

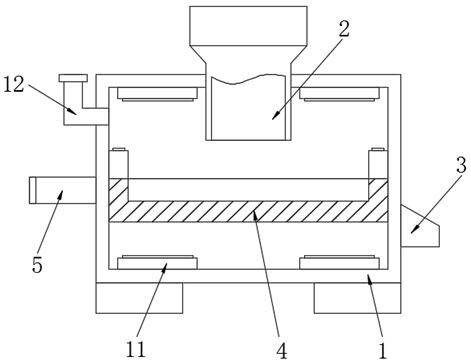

[0038] See Figure 1-3 Shown, a papermaking filler additives, comprising the following parts by weight of the starting raw soil 80 parts of diatomaceous earth, 5 parts of titanium dioxide composite powder, 6 parts of the modified fly ash, fibrous wollastonite, 1 part of 20 parts of compound flocculant ;

[0039] The packing paper additives prepared by the following steps:

[0040] A step, into the original soil with diatomaceous earth, titanium dioxide composite powder, fly ash and the modified wollastonite fibers kneader, at a rotation speed of 800r / min condition, controlling the internal temperature of the kneader was 40 ℃ , stirred and mixed for 45 min, to give the product a;

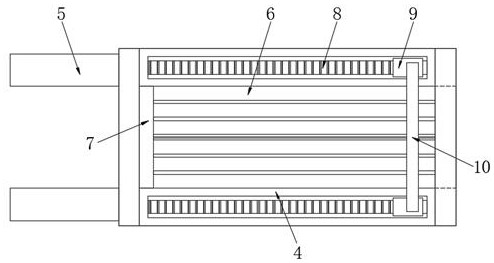

[0041] Step two, the product was put into a drying apparatus for drying, a product 2 is fed by a hopper inside drying box 1, the product falls inside a rack 4 of 5 trough 6, two start linear motor operation switch 9, the two linear motors 9 are two linear slide surface of the slide 8, driven scraper pla...

Embodiment 2

[0052] See Figure 1-3 Shown, a papermaking filler aids, comprising 100 parts by weight of the parts of the original soil material diatomaceous earth, 10 parts of titanium dioxide composite powder, 8 parts of modified fly ash, wollastonite fiber 3 parts, 30 parts Compound Flocculant ;

[0053] The packing paper additives prepared by the following steps:

[0054] A step, into the original soil with diatomaceous earth, titanium dioxide composite powder, fly ash and the modified wollastonite fibers kneader, at a rotation speed of 1200r / min condition, controlling the internal temperature of the kneader was 50 ℃ stirring and mixing 60min, to give the product a;

[0055] Step two, the product was put into a drying apparatus for drying, a product 2 is fed by a hopper inside drying box 1, the product falls inside a rack 4 of 5 trough 6, two start linear motor operation switch 9, the two linear motors 9 are two linear slide surface of the slide 8, driven scraper plate 10 of sub-product ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com