High-shape-preserving comfortable health-care fabric and preparation method thereof

A health-care fabric and comfortable technology, applied in the field of textile manufacturing, can solve problems such as poor environmental protection, insufficient elasticity of fabrics, and poor first-level health care functions, and achieve the ability to enhance elasticity and recover deformation, enhance elasticity, health care functions and environmental protection. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put the PET-1 with an intrinsic viscosity of 0.8 dl / g and the PET-2 with an intrinsic viscosity of 0.4 dl / g into an oven for heating and drying, and put them into the spinning machine in a ratio of 1:1 to slice them, and heat them at 120°C Pre-crystallization for 1 hour, drying at 165°C for 12 hours, followed by melt spinning, melt spinning process parameters: high viscosity PET-1 spinning temperature is 1 zone: 280 ℃, 2 zone: 285 ℃, 3 zone: 290 ℃, four zones: 290℃; the spinning temperature of low viscosity PET-2 is zone one: 290℃, zone two: 295℃, zone three: 295℃, zone four: 290℃; the fluctuation of spinning temperature is ±0.5℃ , the drafting ratio is 3 times, and the winding speed is 600m / min.

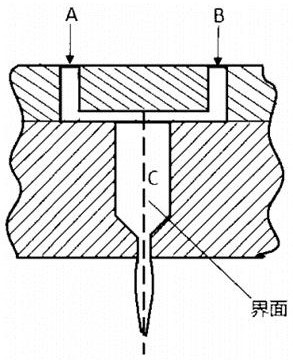

[0032] use as figure 1 In the composite spinning assembly shown, there are two melt flow channels A and B in component 1, and a co-extrusion flow channel C. High viscosity PET-1 and low viscosity PET-2 pass through melt flow channel A and B respectively. B enters the co-ext...

Embodiment 2

[0042] Put PET-1 with an intrinsic viscosity of 1.0 dl / g and PET-2 with an intrinsic viscosity of 0.6 dl / g in an oven, heat and dry them, put them into spinning machines at a ratio of 1: 1, and put them into slices at 120°C Pre-crystallization for 1 hour, drying at 165°C for 12 hours, followed by melt spinning, melt spinning process parameters: High viscosity PET-1 spinning temperature is 1st zone: 280°C, 2nd zone: 286°C, 3rd zone: 290°C , zone four: 290°C; low-viscosity PET-2 spinning temperature is zone one: 285°C, zone two: 290°C, zone three: 290°C, zone four: 285°C; spinning temperature fluctuation is ±0.5°C, pulling The elongation ratio is 3 times, and the winding speed is 600m / min.

[0043] use as figure 1 In the composite spinning assembly shown, there are two melt flow channels A and B in component 1, and a co-extrusion flow channel C. High viscosity PET-1 and low viscosity PET-2 pass through melt flow channel A and B respectively. B enters the co-extrusion flow chan...

Embodiment 3

[0053] Put PET-1 with an intrinsic viscosity of 1.2 dl / g and PET-2 with an intrinsic viscosity of 0.8 dl / g in an oven, heat and dry them, put them into spinning machines at a ratio of 1: 1 and slice them, and heat them at 120°C Pre-crystallization for 1 hour, drying at 165°C for 12 hours, followed by melt spinning, the process parameters of melt spinning: high viscosity PET-1 spinning temperature is 1st zone: 280°C, 2nd zone: 285°C, 3rd zone: 285°C , zone four: 280°C; low-viscosity PET-2 spinning temperature is zone one: 287°C, zone two: 293°C, zone three: 293°C, zone four: 285°C; spinning temperature fluctuation is ±0.5°C, pulling The elongation ratio is 3 times, and the winding speed is 600m / min.

[0054] use as figure 1 In the composite spinning assembly shown, there are two melt flow channels A and B in component 1, and a co-extrusion flow channel C. High viscosity PET-1 and low viscosity PET-2 pass through melt flow channel A and B respectively. B enters the co-extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com