Preparation method and construction method of quick-setting polymer synthetic modified emulsified asphalt water shutoff agent

A technology of emulsified asphalt and water blocking agent, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., which can solve the problems of increasing mining costs, loss of plugging effect, formation plugging and reduction of oil displacement effect and other problems, to achieve the effects of long pressure duration, reduced duration, and improved mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

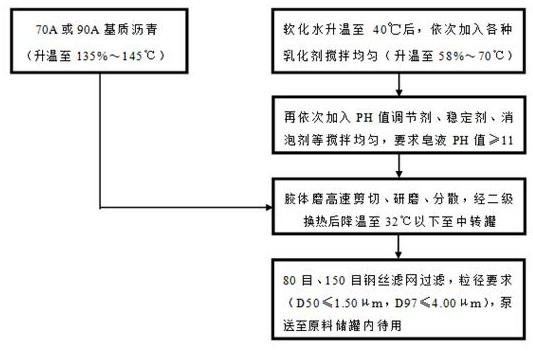

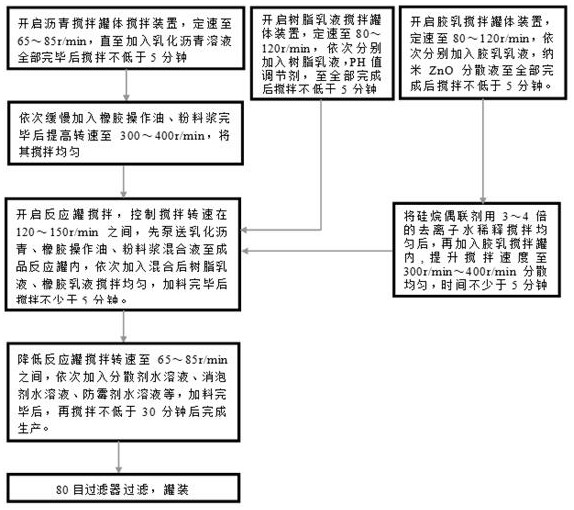

Method used

Image

Examples

Embodiment 1

[0042] 1. Composition

[0043] Composition of anionic emulsified asphalt solution (take 1000 kg formulation quantity as an example)

[0044] Chambord 70A base asphalt 480kg, mid-crack fast-setting type (LT-405A) tall oil anionic emulsifier 7kg, mid-crack fast-setting type (PM-3372) potassium oleate anionic emulsifier 5kg, non-ionic alkylphenol polyoxygen Vinyl ether emulsifier (OP-10) 2.0kg, isotridecyl alcohol polyoxyethylene ether emulsifier (1310) 2.5kg, non-ionic phosphate emulsifier (RE-610) 1.0kg, sodium carboxymethylcellulose (CMC) 0.8 kg, silicone defoamer (BYK-024) 0.6 kg, sodium hydroxide 50% aqueous solution 1.9 kg, demineralized water 499.2 kg.

[0045] Composition of powder slurry (take 100 kg formula quantity as an example)

[0046] Nano light calcium carbonate 23kg, wollastonite 18kg, kaolin 14kg, sodium bentonite 1.5, sodium hydroxide 0.3kg, polyacrylic acid ammonium salt dispersant 1.8kg, alkyl polyoxyethylene ether (OP-20) 0.6kg, isomer thirteen Alcohol po...

Embodiment 2

[0060] 1. Composition

[0061] Composition of anionic emulsified asphalt solution (take 1000 kg formulation quantity as an example)

[0062] Chambord 70A base asphalt 522kg, mid-crack fast-setting type (LT-405A) tall oil anionic emulsifier 8.5kg, mid-crack fast-setting type (PM-3372) potassium oleate anionic emulsifier 5.3kg, non-ionic alkylphenol Polyoxyethylene ether emulsifier (OP-10) 2.7kg, isomeric tridecyl alcohol polyoxyethylene ether emulsifier (1310) 3.1kg, non-ionic phosphate emulsifier (RE-610) 1.3kg, carboxymethyl fiber Sodium plain (CMC) 1.0 kg, silicone defoamer (BYK-024) 0.7 kg, sodium hydroxide 50% aqueous solution 2.1 kg, demineralized water 453.3 kg.

[0063] Composition of powder slurry (take 100 kg formula quantity as an example)

[0064] Nano light calcium carbonate 22 kg, wollastonite 18 kg, kaolin 14 kg, sodium bentonite 1.5, sodium hydroxide 0.3 kg, polyacrylic acid ammonium salt dispersant 1.8 kg, alkyl polyoxyethylene ether (OP-20) 0.6 kg, isomerize...

Embodiment 3

[0070] 1. Composition

[0071] Composition of anionic emulsified asphalt solution (take 1000 kg formulation quantity as an example)

[0072] Chambord 70A base asphalt 497kg, mid-crack fast-setting type (LT-405A) tall oil anionic emulsifier 8kg, mid-crack fast-setting type (PM-3372) potassium oleate anionic emulsifier 5kg, non-ionic alkylphenol polyoxygen Vinyl ether emulsifier (OP-10) 2.5kg, isomerized tridecyl alcohol polyoxyethylene ether emulsifier (1310) 3kg, non-ionic phosphate emulsifier (RE-610) 1.2kg, sodium carboxymethylcellulose ( CMC) 0.9 kg, silicone defoamer (BYK-024) 0.6 kg, sodium hydroxide 50% aqueous solution 2 kg, demineralized water 479.8 kg.

[0073] Composition of powder slurry (take 100 kg formula quantity as an example)

[0074] Nano light calcium carbonate 22.5kg, wollastonite 18kg, kaolin 14.5kg, sodium bentonite 1.5, sodium hydroxide 0.3kg, polyacrylic acid ammonium salt dispersant 1.8kg, alkyl polyoxyethylene ether (OP-20) 0.6kg, isomerization Tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com