Preparation method of MPP electric power tube with heat resistance

A technology of heat resistance and power pipe, applied in the field of power pipe, can solve the problems of shortening the service life of the pipe, oxidation and brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a MPP power tube with heat resistance, and the preparation method of the MPP power tube with heat resistance includes the following process:

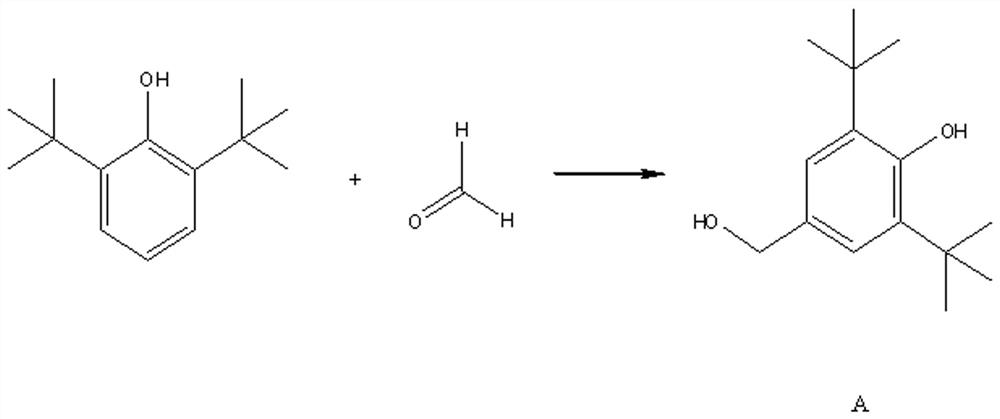

[0046] S1: Weigh 60 parts of polypropylene, 10 parts of glass fiber, 4 parts of silane coupling agent, 5 parts of stearic acid, 3 parts of paraffin and 2 parts of antioxidant by weight and mix them evenly to obtain electricity Pipe heat-resistant layer blend;

[0047] S2: Prepare the material for the flame-retardant layer of the power tube;

[0048] S3: Add the power tube heat-resistant layer blend and power tube flame-retardant layer material prepared in S1 and S2 to different silos for drying and preheating, and extrude through a single-screw extruder;

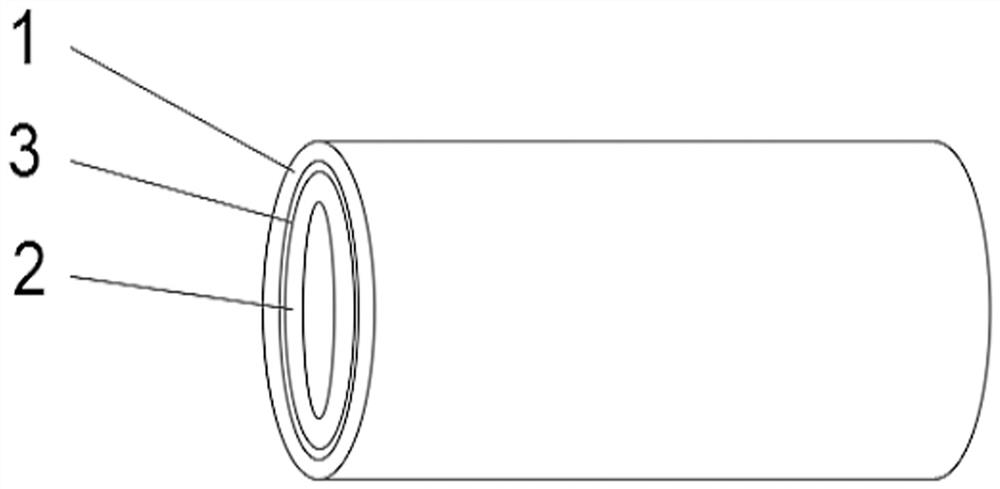

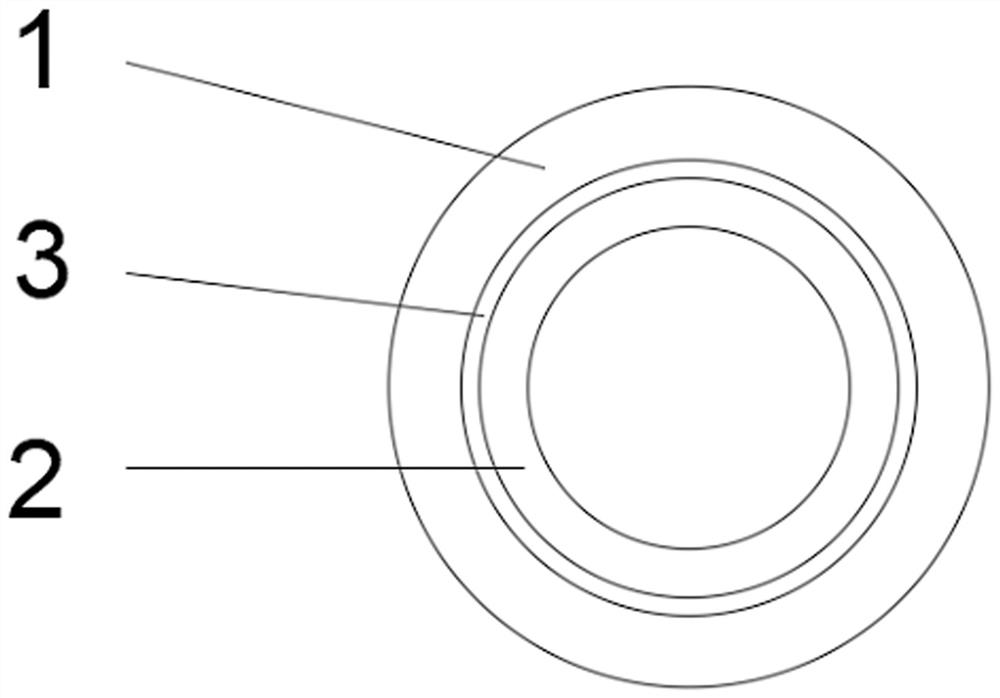

[0049] S4: Double-layer co-extrusion method is used to extrude the heat-resistant layer 1 of the power tube and the flame-retardant layer 2 of the power tube through a single-screw extruder, and the materials are heated, melted, and plasticized by the extrud...

Embodiment 2

[0060] This embodiment is a MPP power tube with heat resistance, and the preparation method of the MPP power tube with heat resistance includes the following process:

[0061] S1: Weigh 60 parts of polypropylene, 10 parts of glass fiber, 2 parts of silane coupling agent, 1 part of stearic acid, 1 part of paraffin and 1 part of antioxidant in parts by weight and mix evenly to obtain electricity Pipe heat-resistant layer blend;

[0062] S2: Prepare the material for the flame-retardant layer of the power tube;

[0063] S3: Add the power tube heat-resistant layer blend and power tube flame-retardant layer material prepared in S1 and S2 to different silos for drying and preheating, and extrude through a single-screw extruder;

[0064] S4: Double-layer co-extrusion method is used to extrude the heat-resistant layer 1 of the power tube and the flame-retardant layer 2 of the power tube through a single-screw extruder, and the materials are heated, melted, and plasticized by the extru...

Embodiment 3

[0075] This embodiment is a MPP power tube with heat resistance, and the preparation method of the MPP power tube with heat resistance includes the following process:

[0076] S1: Weigh 70 parts of polypropylene, 30 parts of glass fiber, 4 parts of silane coupling agent, 5 parts of stearic acid, 3 parts of paraffin and 2 parts of antioxidant by weight and mix them evenly to obtain electricity Pipe heat-resistant layer blend;

[0077] S2: Prepare the material for the flame-retardant layer of the power tube;

[0078] S3: Add the power tube heat-resistant layer blend and power tube flame-retardant layer material prepared in S1 and S2 to different silos for drying and preheating, and extrude through a single-screw extruder;

[0079] S4: Double-layer co-extrusion method is used to extrude the heat-resistant layer 1 of the power tube and the flame-retardant layer 2 of the power tube through a single-screw extruder, and the materials are heated, melted, and plasticized by the extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com