Carboxylate/phosphate dual dynamic covalent polymer network material and preparation method thereof

A technology of phosphate and carboxylate, applied in the field of crystallizable carboxylate/phosphate dual dynamic covalent polymer network materials and its preparation, can solve the problems of slow remodeling and complicated preparation process, and achieve operability Strong, simple preparation process, and improved remodeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Specifically, as an aspect of the technical solution of the present invention, the preparation method of a carboxylate / phosphate ester double dynamic covalent polymer network material includes: making a cyclic acid anhydride containing a long-chain side group, a ring Oxygen monomers and phosphoric acid group-containing compounds are pre-reacted in a uniformly mixed reaction system, and then undergo a curing reaction to obtain carboxylate / phosphate ester dual dynamic covalent polymer network materials (also denoted as "long-chain side group-containing Crystalline Carboxylate / Phosphate Dual Dynamic Covalent Polymer Network Materials").

[0020] The reaction mechanism of the present invention is: the present invention proposes the preparation method of the crystallizable carboxylate / phosphate dual dynamic covalent polymer network material containing long-chain side groups. The ring-opening curing reaction of the cyclic anhydride and the phosphoric acid group-containing com...

Embodiment 1

[0038] Mix diglycidyl hexahydrophthalate, dodecenyl succinic anhydride, and N-(phosphorylmethyl) glycine in a single-necked flask at a molar ratio of 1:1.33:0.34; place the mixed system at 120 Pre-react in an oil bath at ℃ for 1 h; pour the pre-reaction product into a polytetrafluoroethylene mold, put the mold into a vacuum oven, and vacuumize; the control system is cured under vacuum conditions, and the curing process is 15 °C for 2 h, 190 ℃ for 2 hours; after natural cooling, the solidified product was taken out of the oven to obtain a transparent light yellow film material (ie, the aforementioned crystallizable transesterification-type dynamic covalent polymer network material containing long-chain side groups).

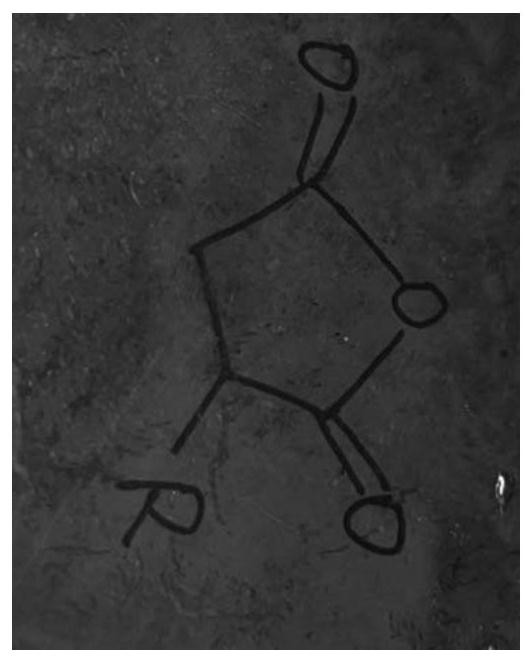

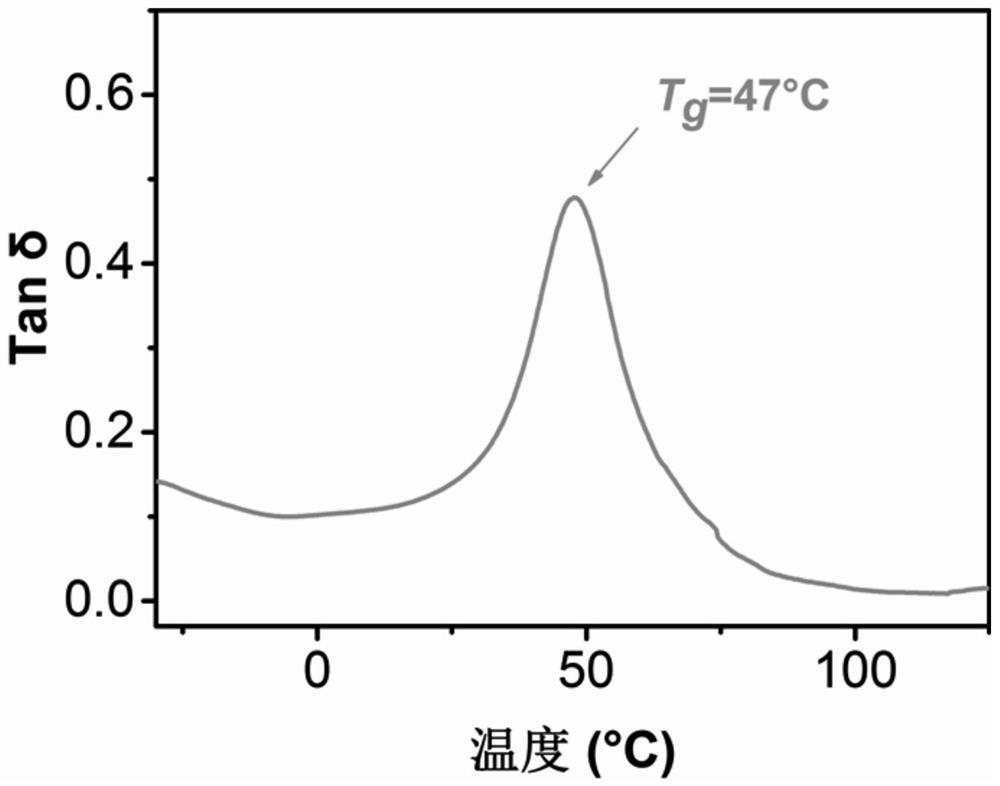

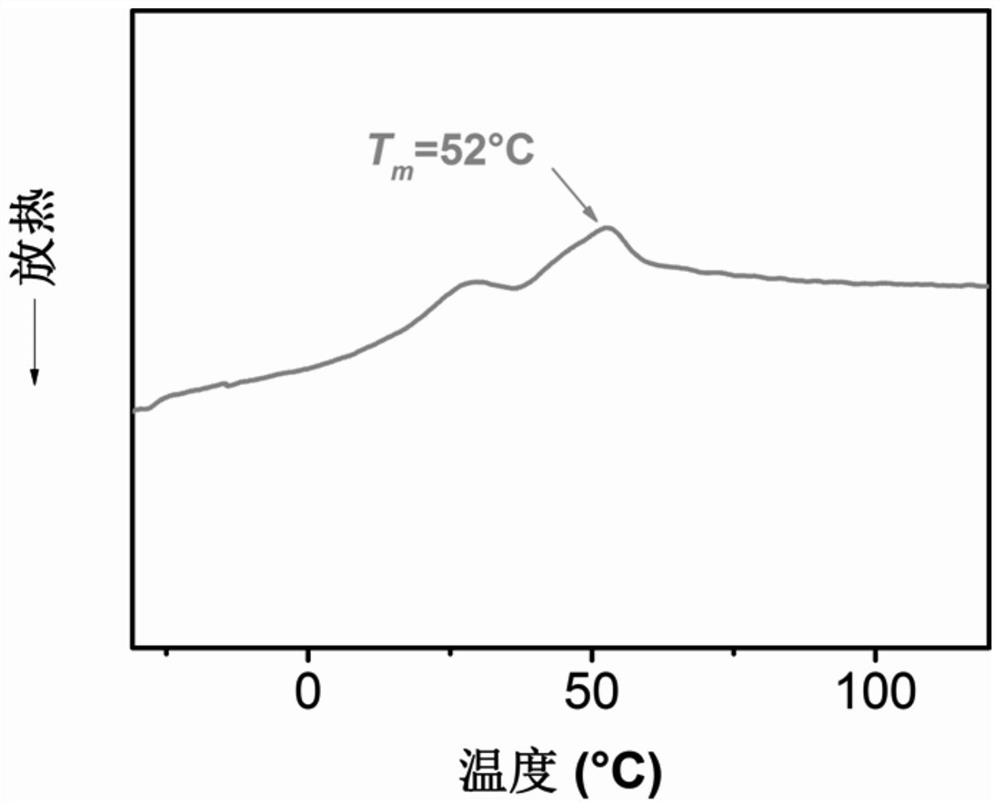

[0039] After the polymer network material prepared in this example was cut into pieces, it was hot-pressed at 160°C for 10 minutes using a flat vulcanizer, and the complete material ( figure 1 ). Also, the material has a glass transition temperature of 47°C ( f...

Embodiment 2

[0041] Mix diglycidyl hexahydrophthalate, dodecyl succinic anhydride, and N-(phosphorylmethyl) glycine in a single-necked flask at a molar ratio of 1:1.33:0.34; place the mixed system in Pre-react in an oil bath at 120°C for 2 hours; pour the pre-reaction product into a polytetrafluoroethylene mold, put the mold into a vacuum oven, and vacuumize; the control system is cured under vacuum conditions, and the curing process is 150°C for 1 hour , React at 190°C for 2 hours; after natural cooling, take the solidified product out of the oven to obtain a transparent light yellow film material.

[0042] After the polymer network material prepared in this example is cut into pieces, it can be hot-pressed at 130°C for 20 minutes with a flat vulcanizer, and the complete material can be obtained again. Please refer to figure 1 shown. Moreover, the glass transition temperature of the material is 55°C, the crystalline melting temperature is 67°C, the elongation at break is 150%, the Young'...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com