A high-temperature bending-resistant porous ceramic material and its preparation method and application

A porous ceramic and high-temperature technology, applied in the field of preparation of ceramic materials, can solve problems such as inapplicable metal melt purification, unfavorable industrial production, complicated process flow, etc., to improve high-temperature mechanical properties, thermal shock stability, and high-temperature mechanical properties Excellent thermal shock stability, high efficiency filtration and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In an alternative embodiment, boride-Al 2 O 3 -The preparation method of the MgO slurry includes: the boride-Al 2 O 3 -MgO powder, vegetable adhesive and deionized water, wet mixed uniformly to obtain B 2 O 3 -Al 2 O 3 -MgO slurry.

[0034] Preferably, boride-Al 2 O 3 -The mass ratio of MgO powder, vegetable adhesive and deionized water is 100:3~12:25~40.

[0035] Preferably, the vegetable adhesive is one of starch glue, dextrin glue, carboxymethyl cellulose glue, and lignin glue.

[0036] In an alternative embodiment, boride-Al 2 O 3 -The preparation of MgO powder includes: combining boride, α-alumina (α-Al 2 O 3 ) and magnesium oxide (MgO) are mixed uniformly by a three-dimensional mixer.

[0037] Preferably, borides, α-alumina (α-Al 2 O 3 ) and magnesium oxide (MgO) in a mass ratio of 1:0.6 to 1:0.4 to 0.6.

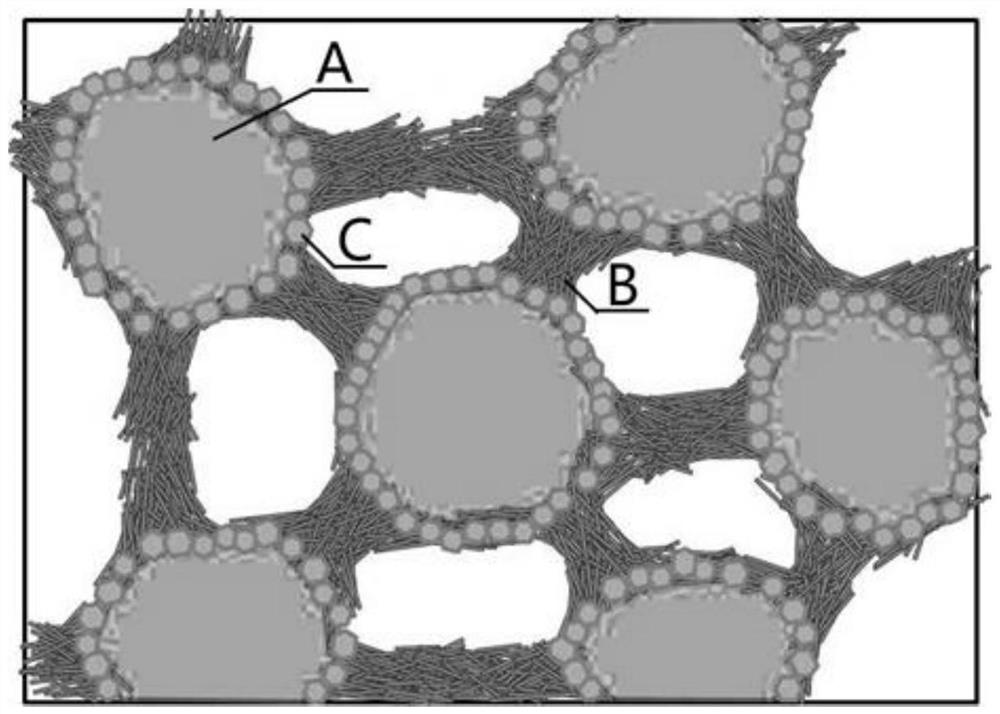

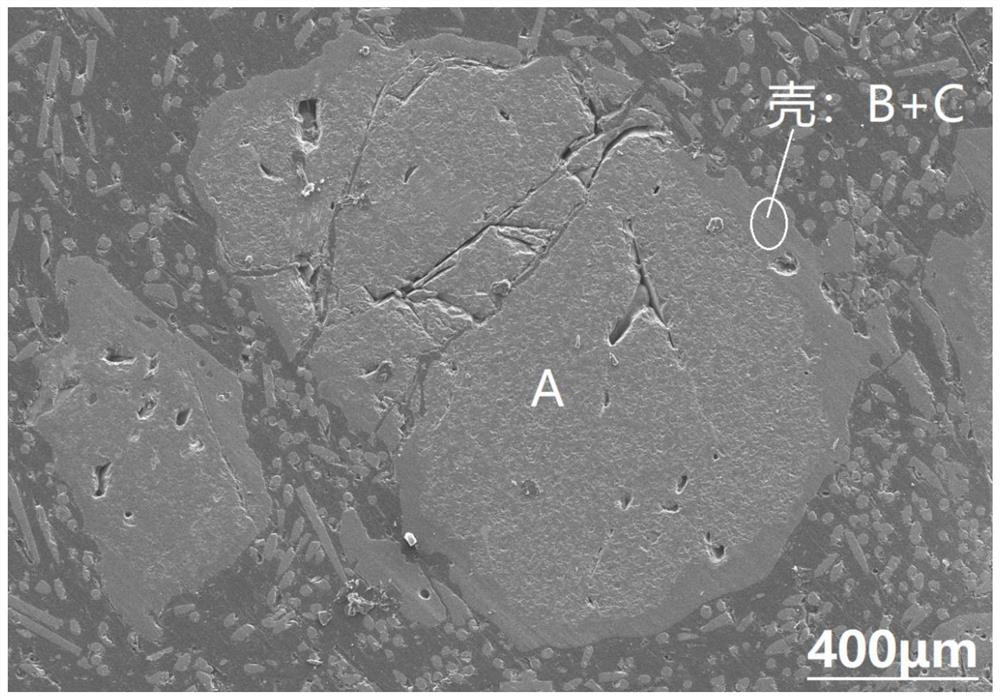

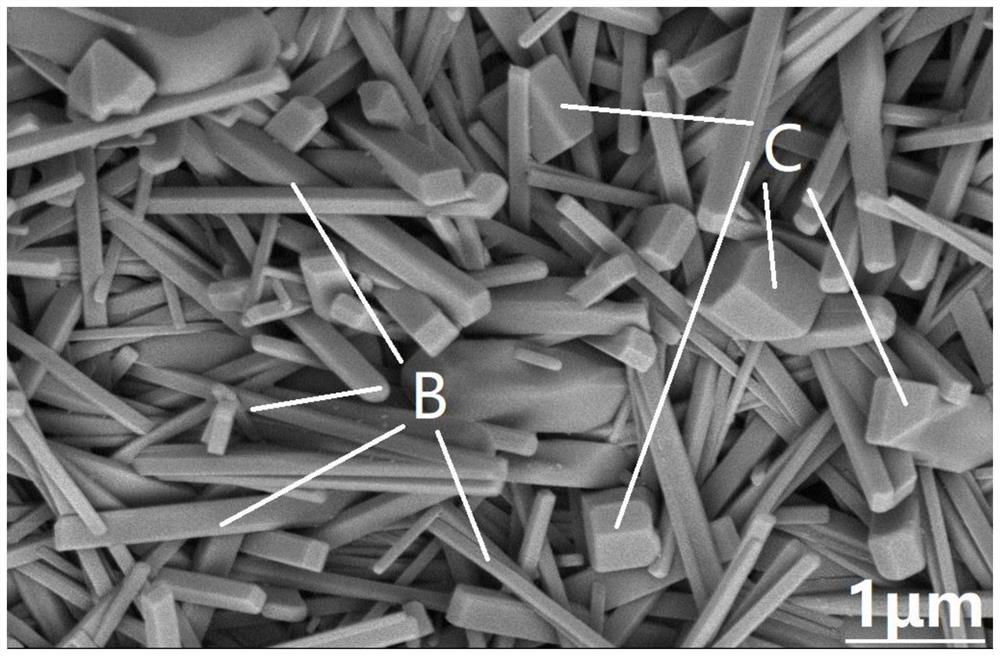

[0038] Boride-Al prepared by the above ratio 2 O 3-After the MgO slurry is sintered by endogenous reaction, the magnesia-aluminum spinel tend...

Embodiment 1

[0053] Preparation B 2 O 3 -Al 2 O 3 -MgO powder: weigh industrial grade boron oxide (B 2 O 3 ), α-alumina (α-Al 2 O 3 ), magnesium oxide (MgO), and mix them uniformly in a three-dimensional mixer according to the mass ratio of 1:0.8:0.4, and the mixing time is 4h to obtain B 2 O 3 -Al 2 O 3 -MgO mixed powder;

[0054] Preparation B 2 O 3 -Al 2 O 3 -MgO slurry: B with a mass ratio of 100:3:25 2 O 3 -Al 2 O 3 -MgO mixed powder, starch glue, deionized water ingredients, added to the mixer for wet mixing for 2h, to obtain B 2 O 3 -Al 2 O 3 -MgO slurry;

[0055] Preparation of thixotropic ceramic blanks: the above B 2 O 3 -Al 2 O 3 -MgO slurry and white corundum alumina ceramic particles are mixed in a mass ratio of 1:4, the particle size of white corundum alumina ceramic particles is 10-20 mesh, and the three-dimensional mixer is used to mix for 2 hours, so that B 2 O 3 -Al 2 O 3 -MgO slurry is well coated on the surface of alumina ceramic particles ...

Embodiment 2

[0061] Preparation B 2 O 3 -Al 2 O 3 -MgO powder: weigh industrial grade boron oxide (B 2 O 3 ), α-alumina (α-Al 2 O 3 ), magnesium oxide (MgO), and mix them uniformly in a three-dimensional mixer according to the mass ratio of 1:1:0.6, and the mixing time is 12h to obtain B 2 O 3 -Al 2 O 3 -MgO mixed powder;

[0062] Preparation B 2 O 3 -Al 2 O 3 -MgO slurry: B with a mass ratio of 100:12:25 2 O 3 -Al 2 O 3 - MgO mixed powder, dextrin glue and deionized water are added into the mixer for wet mixing for 8h to obtain B 2 O 3 -Al 2 O 3 -MgO slurry;

[0063] Preparation of thixotropic ceramic blanks: the above B 2 O 3 -Al 2 O 3 -MgO slurry and brown corundum alumina ceramic particles are mixed in a mass ratio of 1:6. The particle size of the brown corundum alumina ceramic particles is 5-10 meshes. The three-dimensional mixer is used to mix for 6 hours, so that B 2 O 3 -Al 2 O 3 -MgO slurry is well coated on the surface of alumina ceramic particles to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com