In-situ manufacturing method of continuous fiber reinforced soft and hard mixed thermoplastic-based component

A continuous fiber, soft-hard hybrid technology, applied in the field of in-situ manufacturing of continuous fiber-reinforced soft-hard hybrid thermoplastic base components, can solve the problems of poor interface fusion of soft-hard hybrid materials, poor mechanical properties of soft-hard hybrid materials, etc. Chemical printing requirements, good mechanical properties, good fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

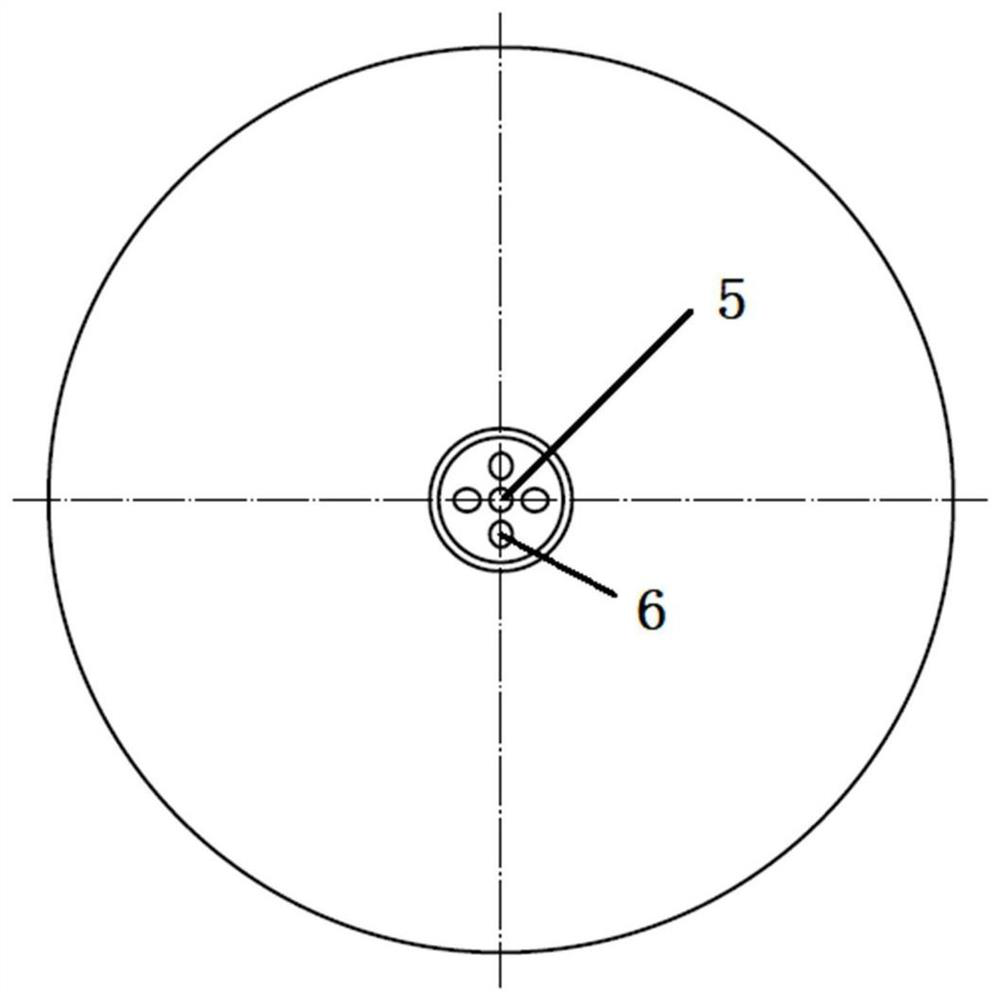

[0036] Such as figure 1 As shown, a continuous fiber reinforced soft-hard hybrid thermoplastic matrix member in-situ manufacturing method, including:

[0037] Step 1, input the model that needs to be manufactured and the corresponding process parameters: including layer thickness δ, interpolation accuracy I, nozzle posture P in the printing coordinate system N , printing speed S and nozzle control temperature T, etc.

[0038] Step 2: Slicing the input model according to the input layer thickness δ to obtain an initial slice path Path with n layers.

[0039] Step 3, calculate and obtain the center point P of the first layer of the slice path Path c , and bias the Path to P c The coordinate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com