Composite double-layer catalyst and method for preparing ethylbenzene and/or propylbenzene through carbon dioxide/carbon monoxide hydrogenation coupling benzene alkylation

A composite double-layer, catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, molecular sieve catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

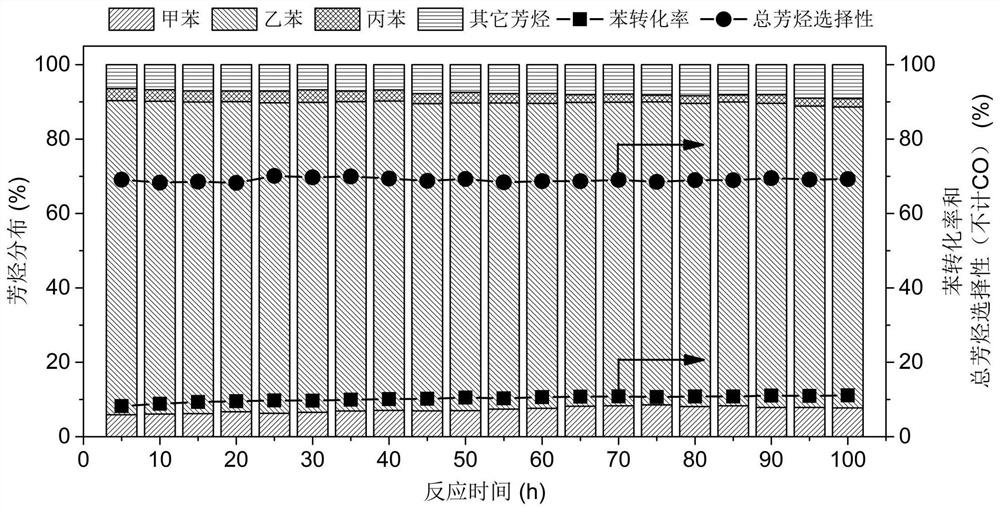

Image

Examples

preparation example Construction

[0039] In the present invention, the preparation method of the CHA molecular sieve preferably comprises the following steps:

[0040] Mixing silicon source, aluminum source, phosphorus source, template agent and polar solvent (hereinafter referred to as the second mixing) for hydrothermal reaction to obtain CHA molecular sieve precursor;

[0041] The CHA molecular sieve precursor is calcined (hereinafter referred to as the second calcination) to obtain the CHA molecular sieve.

[0042] In the invention, silicon source, aluminum source, phosphorus source, template agent and polar solvent are mixed for hydrothermal reaction to obtain CHA molecular sieve precursor. In the present invention, the silicon source is preferably one or more of silica sol, silicon dioxide, white carbon black, tetraethyl orthosilicate, tetrapropyl orthosilicate and water glass, more preferably silicon Sol or silicon dioxide, the silicon dioxide is preferably nano silicon dioxide, and the particle size o...

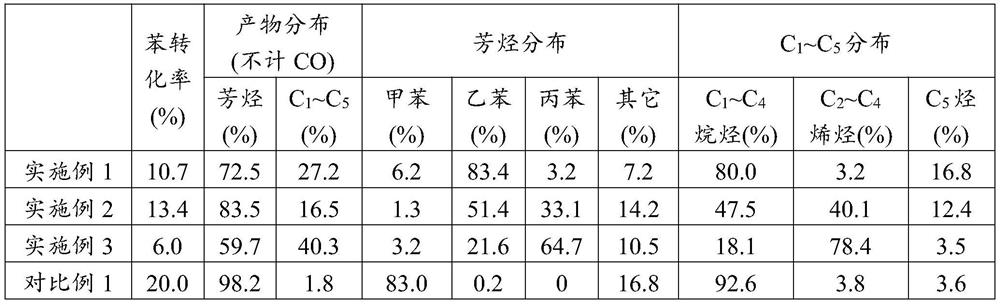

Embodiment 1

[0088] Ammonium carbonate aqueous solution is added dropwise in the mixed solution of zinc nitrate and zirconium nitrate (the molar concentration of zinc ion is 0.01mol / L, and the molar concentration of zirconium ion is 0.1mol / L), carries out co-precipitation reaction, after reaction finishes, After centrifuging and washing the solid product with deionized water until the washing liquid is neutral, put the solid product in an oven for drying at a drying temperature of 100°C. After drying to constant weight, the solid product is calcined at a temperature of 500 ℃, the holding time for calcination is 3h, and the heating rate from room temperature to the temperature of calcination is 5℃ / min to obtain ZnZrO x .

[0089] Silica sol, pseudoboehmite, phosphoric acid, tetraethylammonium hydroxide and deionized water are mixed for hydrothermal reaction, wherein tetraethylammonium hydroxide, silica sol (calculated as silicon dioxide), pseudoboehmite The molar ratio of bauxite (calculat...

Embodiment 2

[0094] Ammonium carbonate aqueous solution is added dropwise in the mixed solution of zinc nitrate and zirconium nitrate (the molar concentration of zinc ion is 0.01mol / L, and the molar concentration of zirconium ion is 0.1mol / L), carries out co-precipitation reaction, after reaction finishes, After centrifuging and washing the solid product with deionized water until the washing liquid is neutral, put the solid product in an oven for drying at a drying temperature of 100°C. After drying to constant weight, the solid product is calcined at a temperature of 500 ℃, the holding time for calcination is 3h, and the heating rate from room temperature to the temperature of calcination is 5℃ / min to obtain ZnZrO x .

[0095] Silica sol, pseudoboehmite, phosphoric acid, tetraethylammonium hydroxide and deionized water are mixed for hydrothermal reaction, wherein tetraethylammonium hydroxide, silica sol (calculated as silicon dioxide), pseudoboehmite The molar ratio of bauxite (calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com